LDPE (Low-Density Polyethylene) high-foamed composite aluminized film and preparation method thereof

A high-foaming, composite plating technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve problems such as easy damage, non-wear resistance, and damaged products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

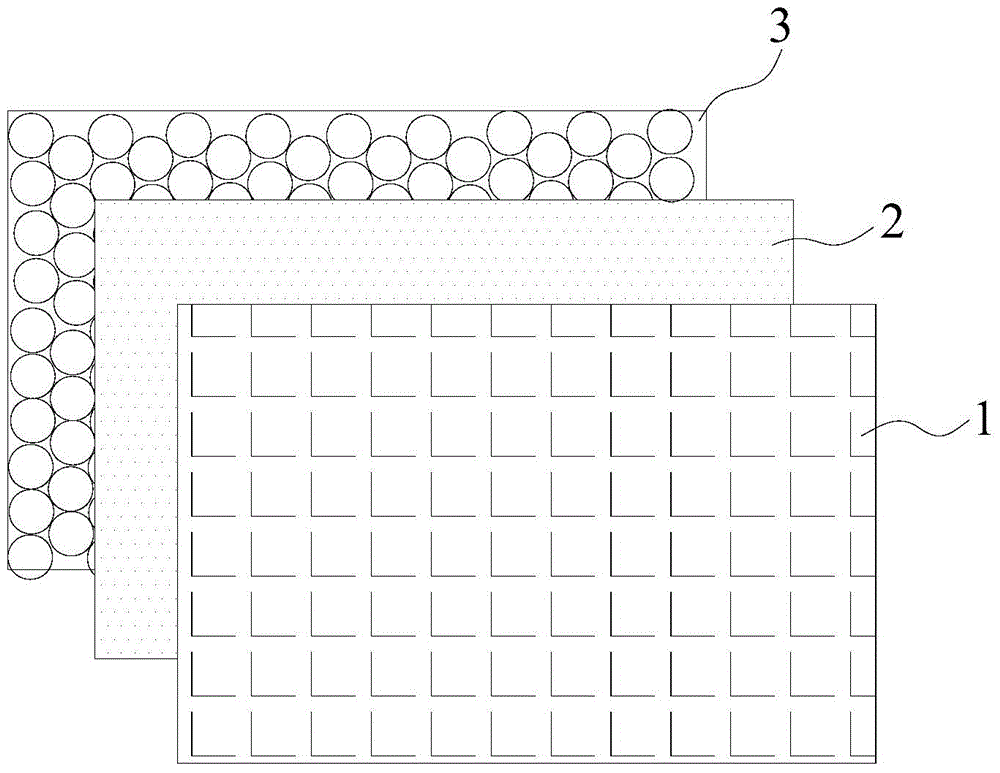

[0040] The LDPE high-foaming composite aluminized film of this embodiment, such as figure 1 As shown, it includes an aluminized film 1, specifically a PET aluminized film, wherein a layer 3 of LDPE formed by high foaming is laminated on the aluminized film 1, that is, a pearl cotton layer, the aluminized film 1 and the sheet A PE adhesive layer 2 is arranged between the material layers 3, that is, the aluminized film 1 and the sheet material layer 3 are bonded together through the PE adhesive layer 2.

[0041] Among them, in order to make the LDPE high-foam composite aluminized film have better strength and shock resistance at the same time, the thickness ratio of the aluminized film 1, the PE adhesive layer 2 and the sheet layer 3 is 1:0.5:2.0. The thickness of the material layer 3 is 1.5 mm.

[0042] The PE adhesive layer used in this embodiment—PE film is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com