Novel dual annular guide rail double rotation parallel mechanism

A ring-shaped guide, double-ring technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of complex structure, inability to support satellites, limiting the rotational ability and flexibility of the mechanism, and achieve the effect of superior stiffness performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Combine below Attached picture The present invention is described in detail with specific examples.

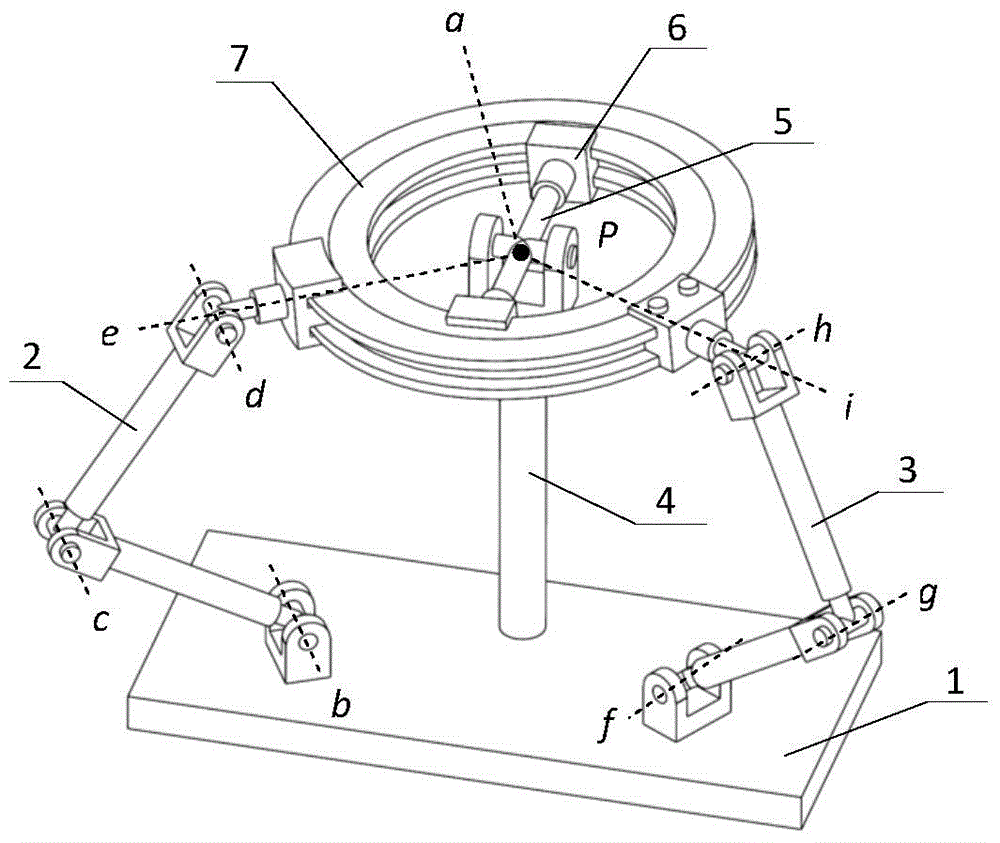

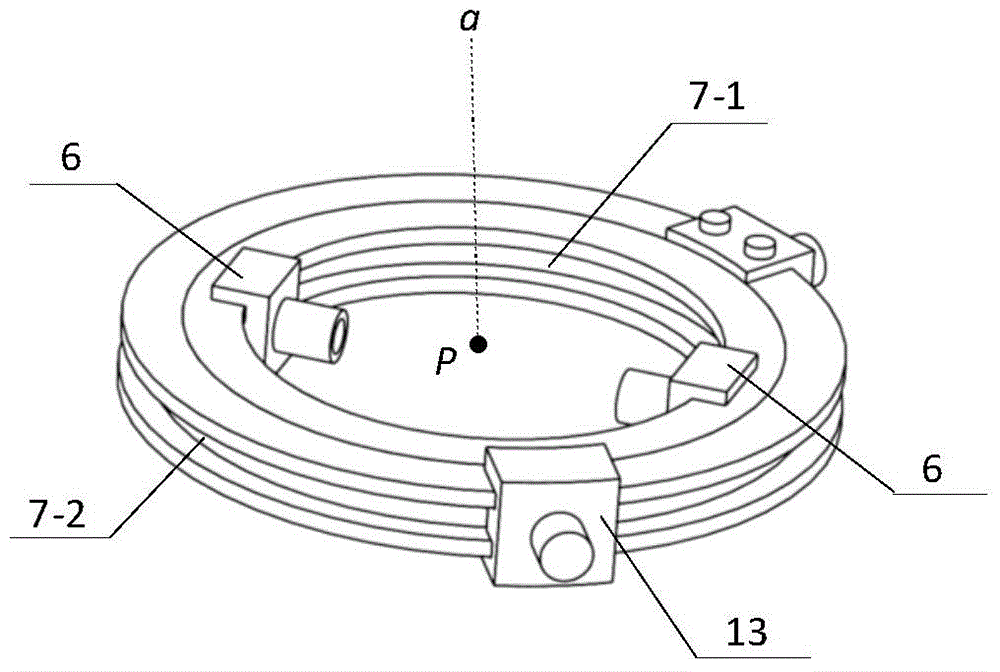

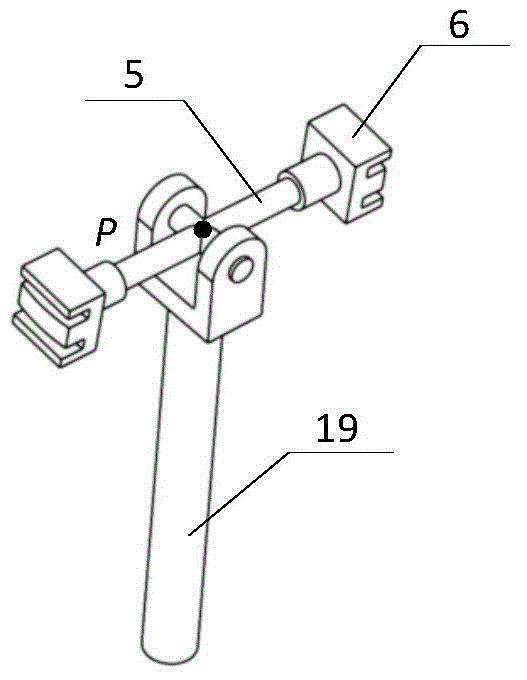

[0018] Such as Attached a kind of present invention new type Double circular guide rail two-rotation parallel mechanism, which includes a static platform 1 and a moving platform 7, and a driven branch chain 4, a first driving branch chain 2 and a second driving branch chain are connected between the static platform 1 and the moving platform 7 Chain 3, the moving platform includes an active circular guide rail 7-2, a driven circular guide rail 7-1 is fixed on the inner wall circumference of the active circular guide rail, and the upper and lower symmetrical center planes of the driven circular guide rail The upper and lower symmetrical center planes of the active annular guide rail coincide with each other, and the center point of the driven annular guide rail coincides with the center point of the active annular guide rail to form the center point of the moving plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com