Intermediate casing ring repairing method

A repair method and intermediary technology, which is applied in the field of intermediary casing ring repair, can solve the problems of intermediary casing scrapping and affecting the deformation of the intermediary casing body, and achieve the effect of reducing repair costs and avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The suspension ring repair method of a kind of intermediary case, comprises the following steps:

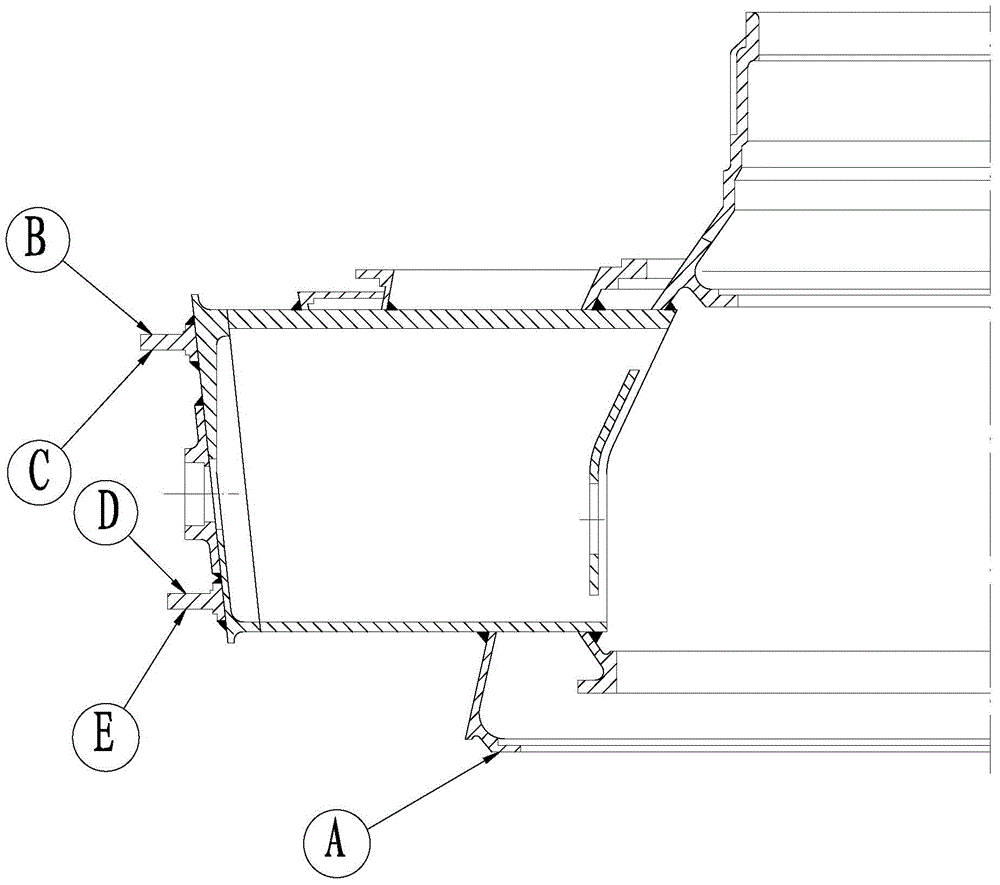

[0038] Step 1: set as figure 1 The intermediate casing shown is hoisted to the workbench of the vertical drilling machine (Z3080X25), and the end surface A is used as the reference plane, and the intermediate casing is aligned by installing side-to-point to ensure that the runout of the end surface B is not greater than 0.02mm, and then through the clamp The tight end face D fixes the intermediate casing on the workbench;

[0039] Step 2: Use a punch to punch a point at the center of the threaded pin, and then use a φ4mm~φ6.8mm drill bit to drill the threaded pin at the punch point in sequence. The drill speed is 150-200r / min, the drilling depth is 10-12mm, and the drill The cutting process is manual feeding, and the drilling de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com