Automatic punch

A punching machine and automatic technology, applied in the field of punching machines, can solve the problems of difficult punching accuracy, poor carrying capacity, time-consuming, etc., and achieve the effect of ensuring automatic production of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

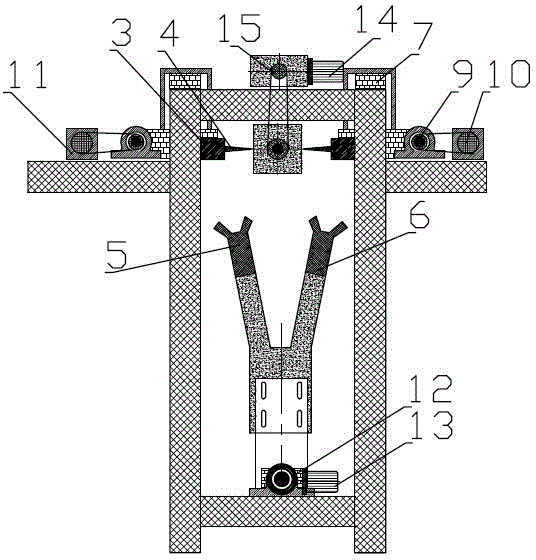

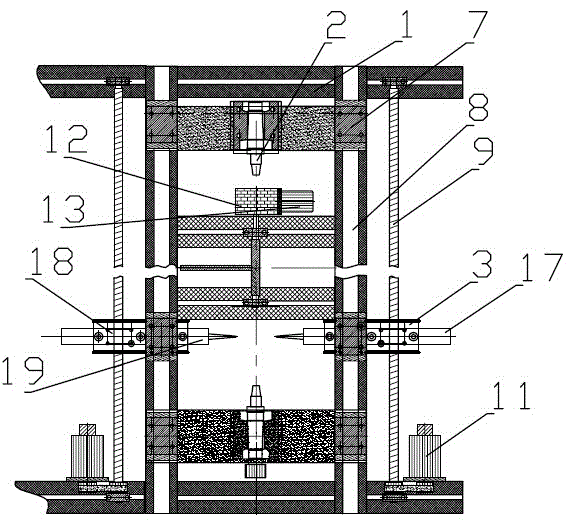

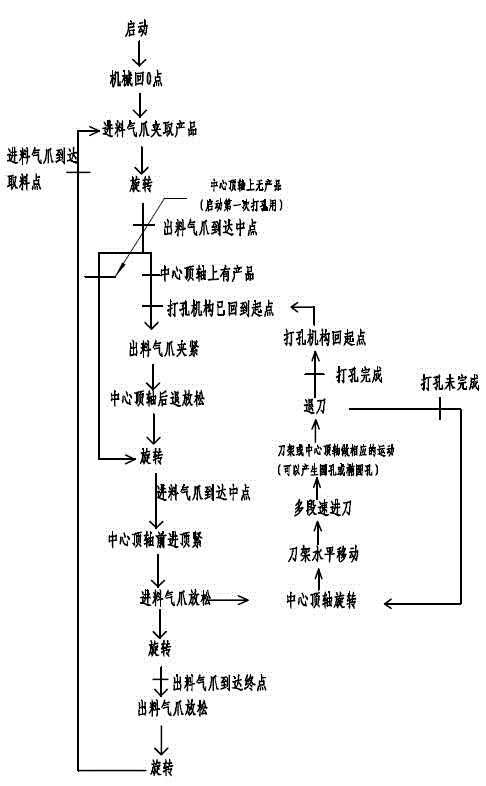

[0019] Such as figure 1 with figure 2 As shown, the present invention provides an automatic punching machine, which includes a body 1, a clamping device that swings laterally is provided on the base of the body 1, and a rotatable working clamping device is provided on the upper end of the body. The working clamping device has a first position for clamping the product and a second position for releasing the clamped product. Both sides of the working clamping device are provided with a punching mechanism that can move parallel to and perpendicular to the product. The clamping The holding device includes a feed air claw 5 and a discharge air claw 6, the feed air claw 5 has a first position for clamping unprocessed products and a second position for swinging and installing unprocessed products on the working clamping device, The discharge air claw 6 has a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com