A self-cleaning air filter device for nuclear power plant air cooling system and its realization method

An air filtration device and air cooling system technology, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of reduced air volume at the air inlet, increased wind resistance, and reduced efficiency of air coolers, so as to ensure normal operation, The effect of reducing wind resistance and ensuring operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

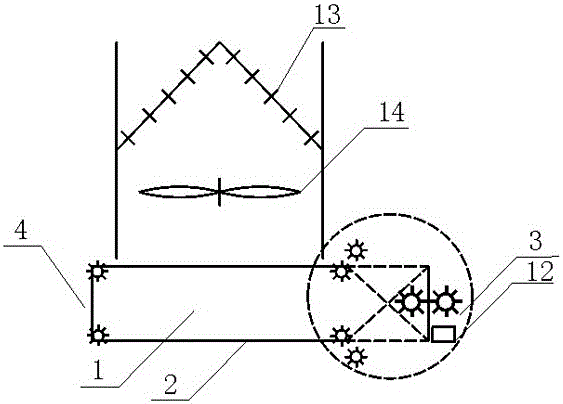

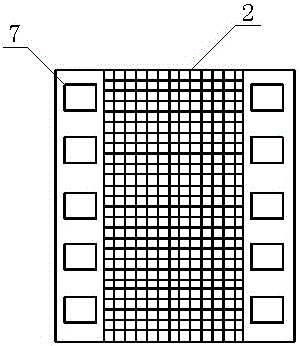

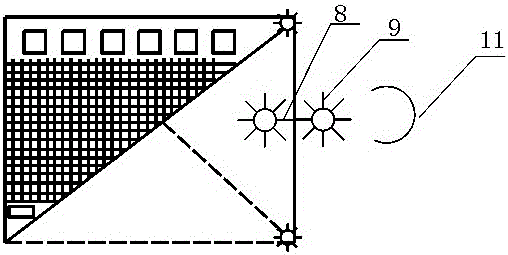

[0027] The invention provides an air filtering device for a nuclear power plant unit type air cooler, such as figure 1 As shown, the air filtering device is arranged under the condensing device, the condensing device includes a finned tube 13 and a fan 14 arranged below the finned tube 13, and the air filtering device includes a frame 1, which is arranged on the frame The metal filter screen 2 on the top 1, the cleaning device 3 located on one side of the metal filter screen 2, the guide device 4, and a group of motors located on the frame 1 (the motor is an internal structure, so it is not shown); as Figure 4 As shown, the guide device 4 includes a guide shaft 5, guide teeth 6 arranged at both ends of the guide shaft 5, the guide teeth 6 are coaxially installed, when embedded in the metal filter screen 2, the The metal filter screen 2 can balance and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com