Electric leakage prevention mechanical structure of electric tool

A technology of electric tools and motor structures, applied in electric components, electrical components, electromechanical devices, etc., can solve problems such as hidden safety hazards and electric tools leakage, and achieve extended service life, good mechanical strength and insulation performance, and avoid rapid aging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

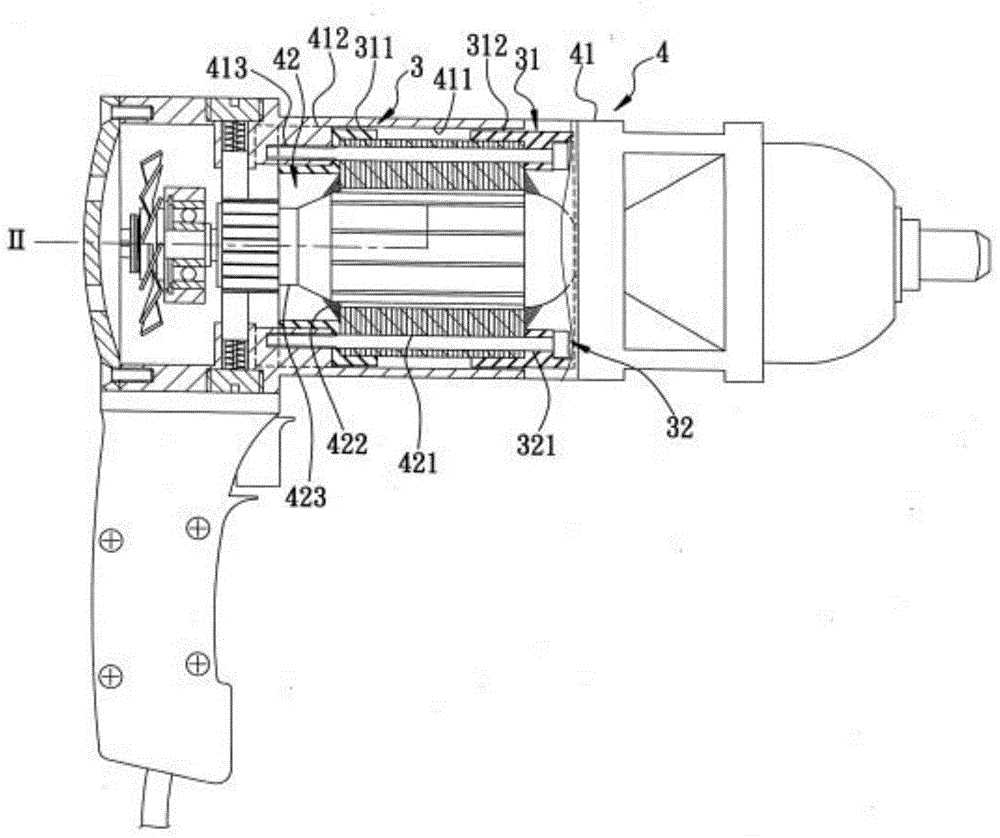

[0022] see figure 1 , shows the anti-leakage motor structure of the electric tool of the present invention.

[0023] The leak-proof motor structure 3 is arranged between the housing 41 of the electric tool 4 and the motor 42, the inner surface 411 of the housing 41 is provided with a plurality of locking parts 412, and each locking part 412 is provided with a The screw hole 413 fixed to the anti-leakage motor structure 4, the motor 42 has a stator 421 assembled on the inner side of the anti-leakage motor structure 3 and arranged in the casing 41 along the axis II and has a plurality of coils 422 , and a rotor 423 that rotates relative to the stator 421.

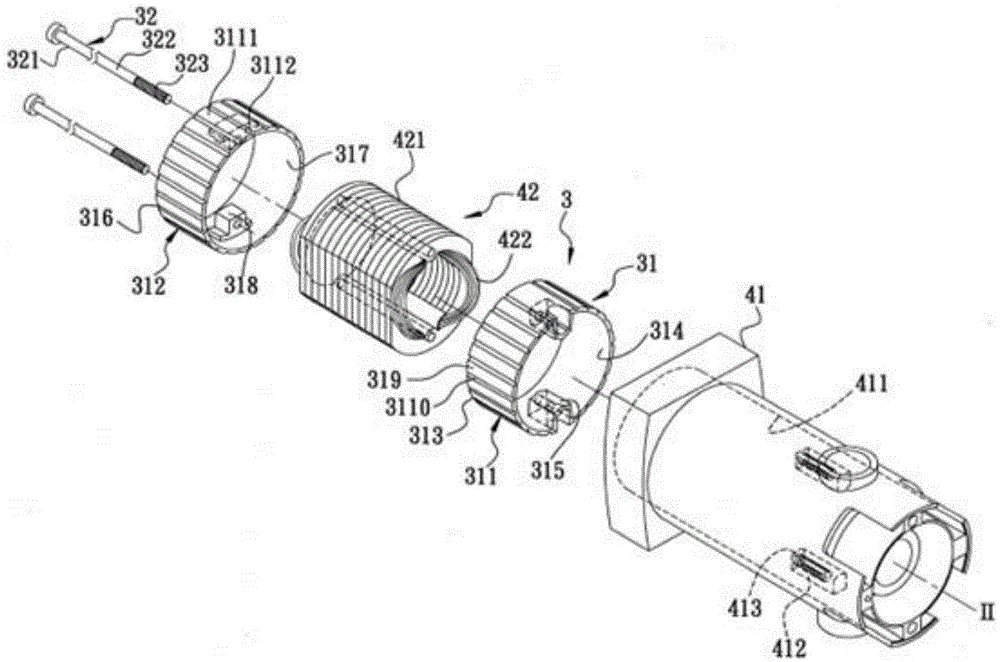

[0024] The leakage-proof motor structure 3 includes a sheath unit 31 disposed between the housing 41 and the motor 42 , and a connection unit 32 combining the sheath unit 31 to the stator 421 and the housing 41 .

[0025] The sheath unit 31 is made of an insulating material (such as phenolic plastic), and includes a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com