Variable-speed LED adhesive dispensing packaging device

A packaging equipment and dispensing technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large overall impact of the workbench and adverse effects of processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

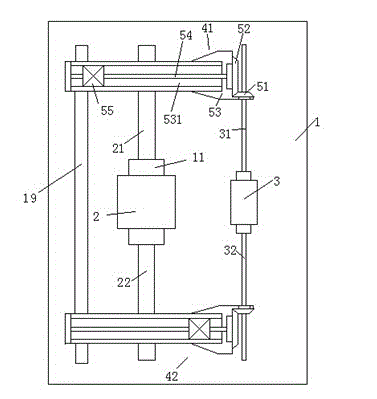

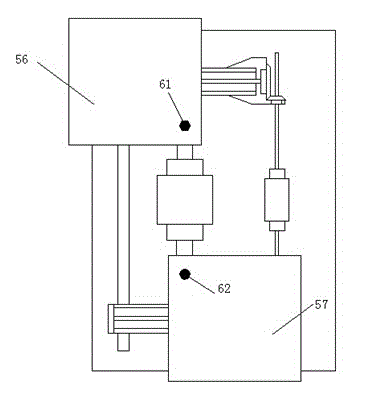

[0014] Attached below Figure 1-2 , the present invention will be described in detail.

[0015] A variable-speed LED dispensing and packaging equipment, including a frame 1, a front slide assembly 42, a rear slide assembly 41, a longitudinal drive motor 2 and a transverse drive motor 3, wherein the frame 1 is longitudinally provided with Rack rail 19, the rear slide assembly 41 and said The front slide assembly 42 is separately arranged on the frame 1 front and back and is slidably matched with the frame guide rail 19; and said The front slide assembly 42 is fixedly arranged on the frame 1, and the front and rear ends of the longitudinal drive motor 2 and the transverse drive motor 3 are provided with gearboxes 11;

[0016] The front end of the longitudinal drive motor 2 is connected to the front longitudinal drive screw 22, the rear end is connected to the rear longitudinal drive screw 21, and the rear longitudinal drive screw 21 is connected to the wire on the rear slide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com