Remote monitoring method and system for oil and gas production

A remote monitoring system and remote monitoring technology, applied in general control systems, electrical program control, control/regulation systems, etc., can solve problems such as the inability to realize remote monitoring, the inability to realize the overall monitoring of equipment-related oil fields, and the inability to share data. To achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

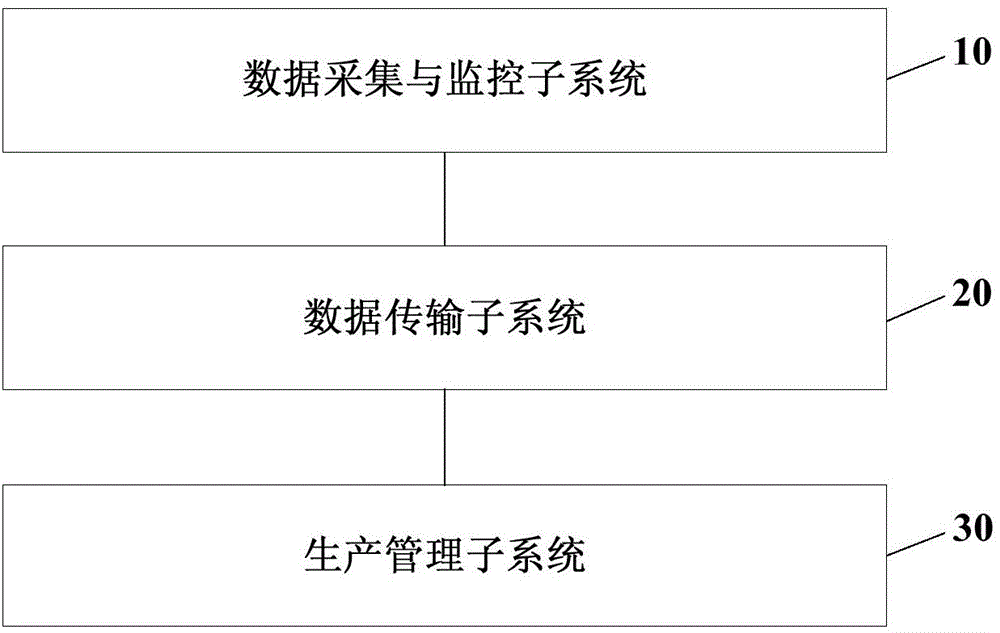

[0024] figure 1 It is a schematic structural diagram of a remote monitoring system according to an embodiment of the present invention. Such as figure 1 As shown, the system includes:

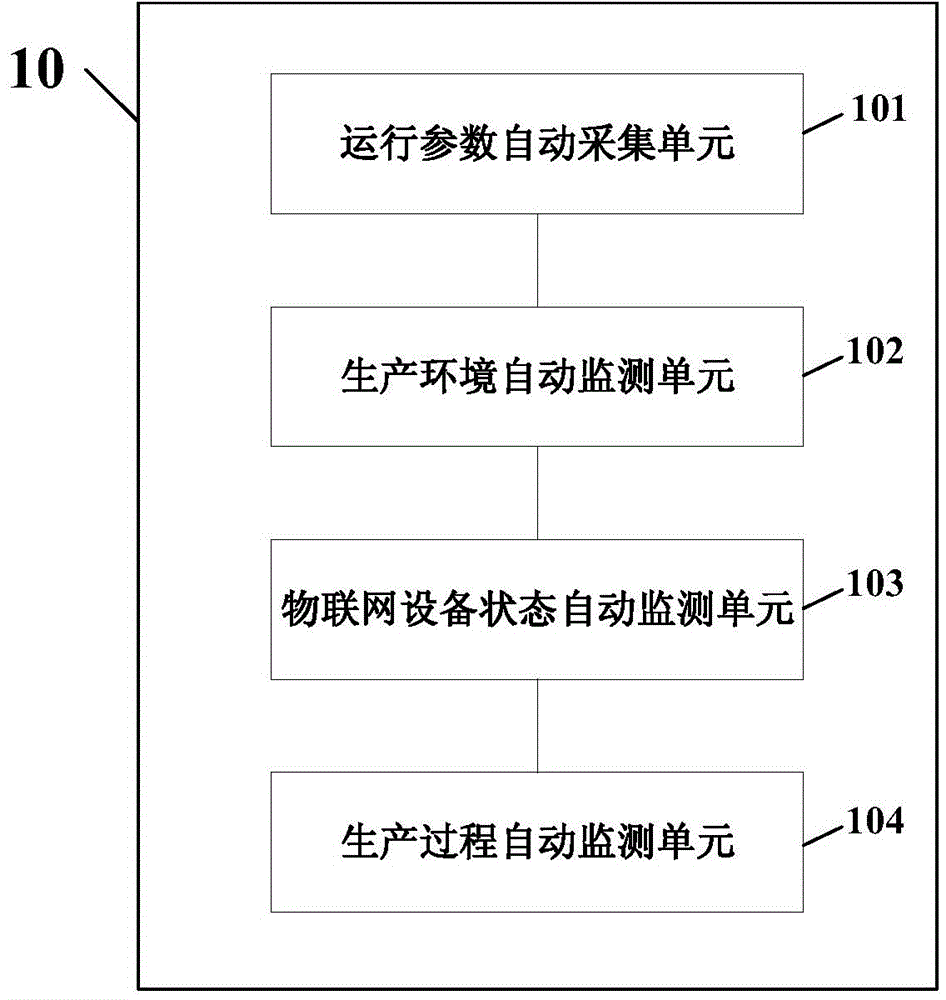

[0025] The data acquisition and monitoring subsystem 10 is set on the oil and gas production site, including sensors installed on the production equipment, RTU (Remote Terminal Unit, remote data terminal) or DCS (Distributed Control System, distributed control system), used for automatic collection State parameters of production equipment, and standardize production state parameters, parameter accuracy, equipment identification and attributes to form monitoring data;

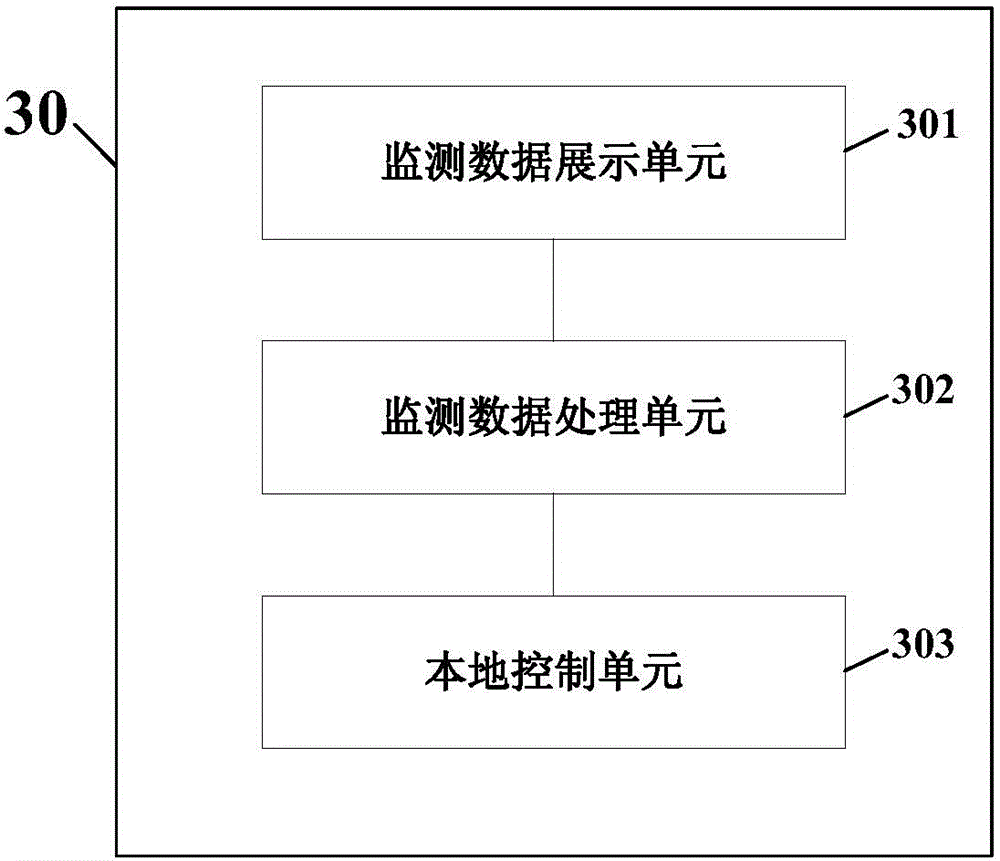

[0026] The data transmission subsystem 20 is used to receive and transmit monitoring data to the production man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com