An automatic optical detection mechanism for a liquid crystal module

An automatic optical detection and liquid crystal module technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as low work efficiency, difficult connection operation, damage to liquid crystal modules, etc., and achieve low probability of missed detection or false detection , to avoid the difficulty of connection operation and to speed up the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

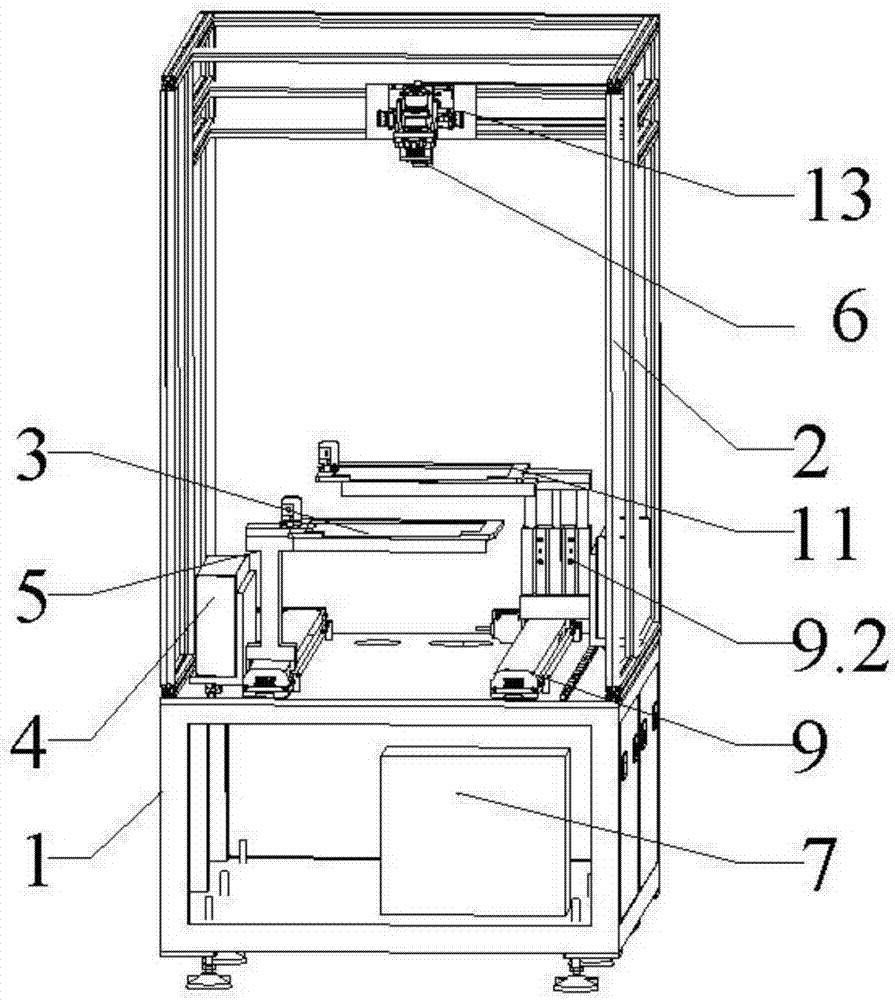

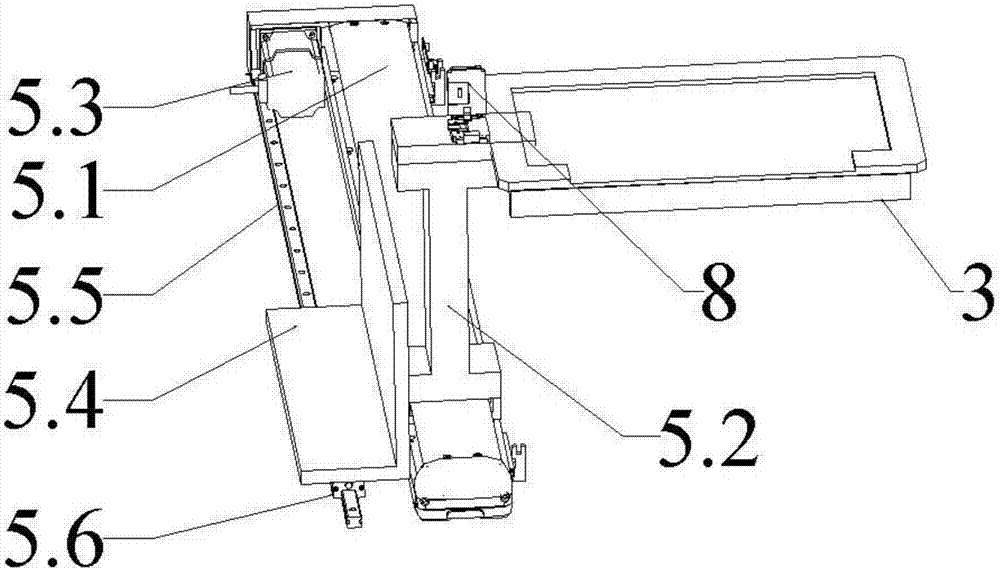

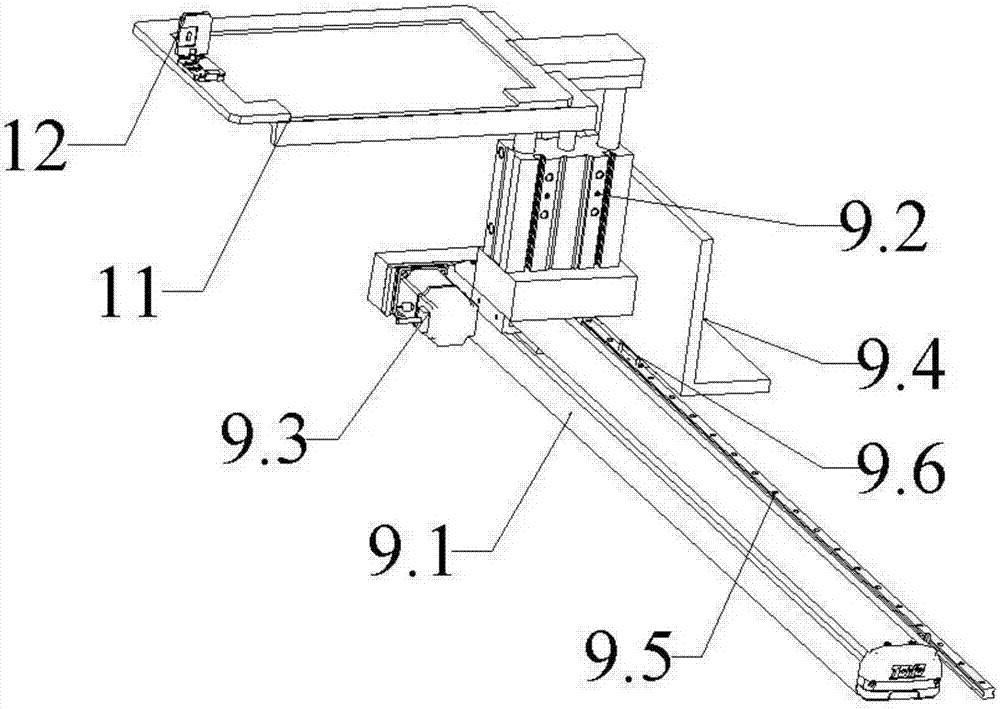

[0031] Such as Figure 1~5 As shown, an automatic optical inspection mechanism for a liquid crystal module includes a carrying platform 1 and a bracket 2 fixed on the upper end of the carrying platform 1. A control unit 7 is arranged inside the carrying platform 1, and a first carrying mechanism is arranged on the upper end surface of the carrying platform 1. Tool 3, the first carrying tool 3 is mainly used to carry the liquid crystal module to ensure that the liquid crystal module can be stably at the position to be detected. The first carrying fixture 3 is generally made according to the shape and size of the liquid crystal module, and a special fixture can also be used to fix the liquid crystal module on the first carrying fixture 3 .

[0032] The carrying platform 1 is also installed with a first graphic signal generating device 4 that sends image signals to the liquid crystal module placed on the first carrying fixture 3, and the first graphic signal generating device 4 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com