An automatic transmission pulley

An automatic variable speed and pulley technology, which is applied to belts/chains/gears, transmission components, transmission devices, etc., can solve the problems of lack of high-quality and low-cost adjustable speed transmission devices, complex and changeable operating objects and environments, and complex speed regulation methods, etc. problem, to achieve the effect of large speed change, convenient installation and use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

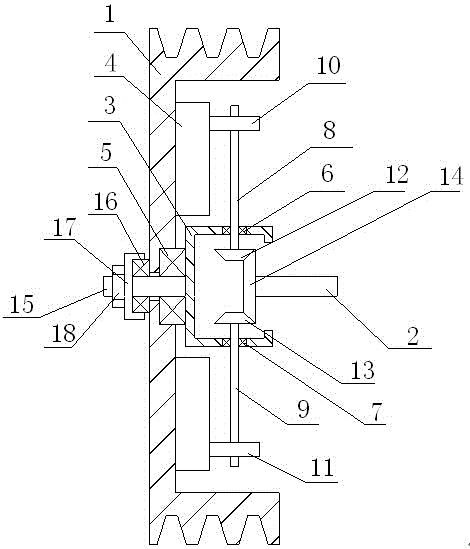

[0015] Such as figure 1 An automatic variable speed pulley shown includes a wheel body 1, a fixed shaft 15, an output shaft 2 and a fixed frame 3, and a friction disc 4 fixedly connected to the wheel body 1 is arranged inside the wheel body 1, and the wheel body 1 is connected and fixed through a bearing a5 The frame 3 and the upper and lower ends of the fixed frame 3 are respectively connected to the transmission shaft a8 and the transmission shaft b9 through the bearing c6 and the bearing d7, and the transmission shaft a8 and the transmission shaft b9 are respectively provided with a friction wheel a10 that can slide along the transmission shaft a8 and the transmission shaft b9 and friction wheel b11, friction wheel a10 and friction wheel b11 press the friction disc 4, the transmission shaft a8 and the transmission shaft b9 mesh with the output gear 14 through the gear a12 and the gear b13 respectively, the output gear 14 is connected to the output shaft 2, and the fixed fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com