Filling mining method of near-horizontal ore body

A backfill mining and ore body technology, applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of high ore recovery rate, small surface damage, large panel production capacity, etc., and achieve high ore recovery rate and filling. The effect of fast bonding and many drainage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

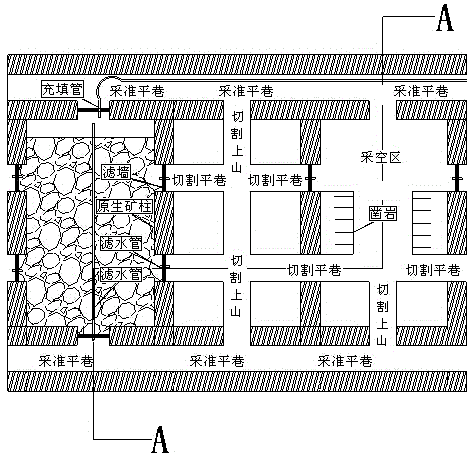

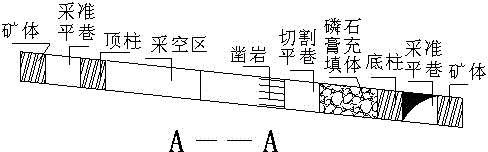

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] When mining the ore blocks in a mine in Kaiyang, Guizhou, the ore body dip angle is about 5°, and the concrete column roof protection mining method is adopted. The exposed area of the empty field is large, the hidden danger of empty area collapse is large, and the cost of concrete column support is high. Low work efficiency.

[0025] Now adopt the near-horizontal thin ore body mining method provided by the invention to carry out filling and mining of the ore body. Firstly, carry out the mining work: construct a mining level road every 42.6 meters along the ore body direction, and adopt the level road anchor net support; cutting work: mine the level road in the vein, and follow the ore body inclination every 23 meters The construction cuts up the mountain and connects with the upper and lower mining level roads to form a large mining house with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com