Method for synthesizing GME zeolite molecular sieve

A technology of zeolite molecular sieve and synthesis method, which is applied in the synthesis field of GME type zeolite molecular sieve, can solve the problems such as high synthesis cost of GME zeolite, and achieve the effects of low cost and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] With 1.0 grams of NaF, 2.29 grams of 30% aqueous sodium hydroxide solution, 7.14 grams of 50% PEG 300 (polyethylene glycol with an average molecular weight of about 300) solution, 10.4 grams of water, 0.78 grams of sodium metaaluminate and The 40% silica sol solution of 7.14 grams is mixed homogeneously, and the molar proportion of gained mixture is:

[0024] 10SiO 2 : Al2O3: 5.0NaF: 2.8Na 2 O: 2.5PEG300: 140H 2 o

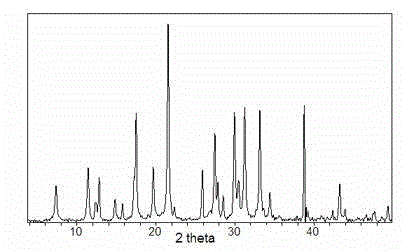

[0025] Move the above mixture into the reactor at 105 o C was crystallized for 120 hours, washed and dried after the reaction, and was identified as a molecular sieve with a GME structure by XRD (see figure 1 ), the content of impurities is less than 1%, and no CHA-type zeolite is found in the product.

[0026]

Embodiment 2

[0028] With 0.5 grams of NaF, 2.29 grams of 30% sodium hydroxide aqueous solution, 7.14 grams of 50% PEG 300 (polyethylene glycol with an average molecular weight of about 300) solution, 10.4 grams of water, 0.78 grams of sodium metaaluminate and The 40% silica sol solution of 7.14 grams is mixed homogeneously, and the molar proportion of gained mixture is:

[0029] 10SiO 2 : Al2O3: 2.5NaF: 2.8Na 2 O: 2.5PEG300: 140H 2 o

[0030] Move the above mixture into the reactor at 105 o C was crystallized for 120 hours. After the reaction was completed, after washing and drying, the main product was identified by XRD as a molecular sieve with a GME structure, and its purity was 98%. No CHA-type zeolite was found in the product.

[0031]

Embodiment 3

[0033] With 1.0 grams of NaF, 2.29 grams of 30% aqueous sodium hydroxide solution, 14.28 grams of 50% PEG 300 (polyethylene glycol with an average molecular weight of about 300) solution, 10.4 grams of water, 0.78 grams of sodium metaaluminate and The 40% silica sol solution of 7.14 grams is mixed homogeneously, and the molar proportion of gained mixture is:

[0034] 10SiO 2 : Al2O3: 5.0NaF: 2.8Na 2 O: 5.0PEG300: 140H 2 o

[0035] Move the above mixture into the reactor at 105 o C was crystallized for 120 hours. After the reaction, after washing and drying, the main product was identified by XRD as a molecular sieve with a GME structure, and its purity was 92%. No CHA-type zeolite was found in the product.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com