Trolley allowing vertical placement of paper tubes

A trolley and paper tube technology, applied in trolleys, multi-axle trolleys, motor vehicles, etc., can solve the problem of unfavorable enterprise management, sorting, rectification, cleaning, cleaning, safety, literacy) management, different types of paper tubes are mixed together, search Models are prone to errors and other problems, so as to achieve the effect of convenient sorting and storage, saving workshop space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

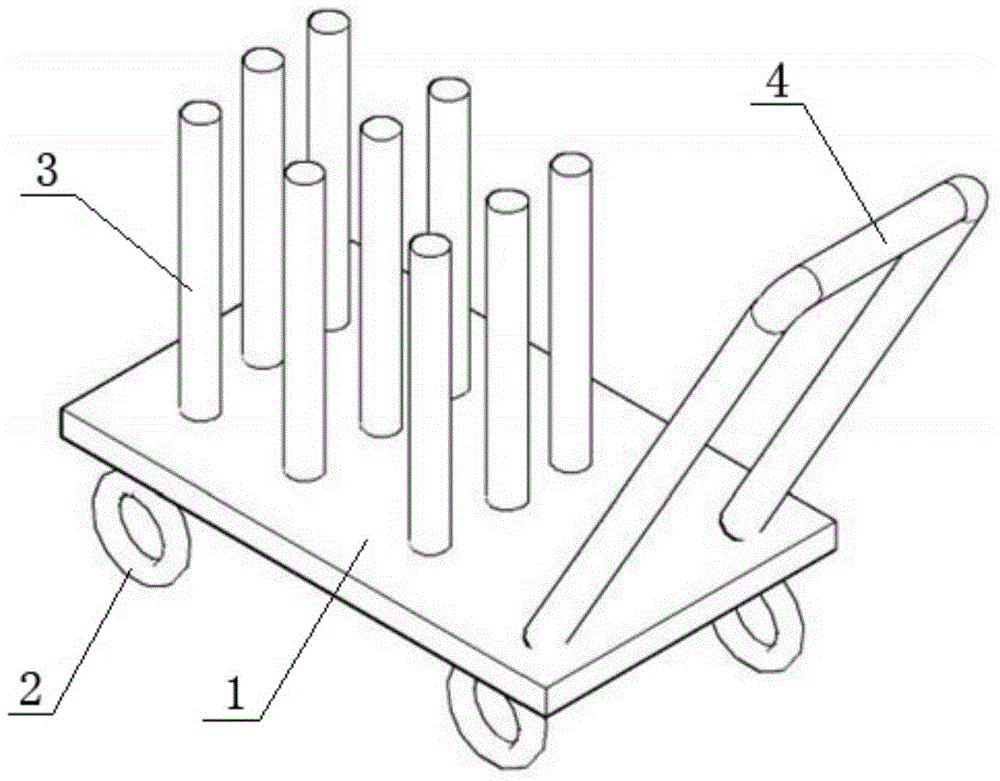

[0010] Such as figure 1 As shown, the trolley in the embodiment that can stand paper tubes is an improvement made on the basis of a conventional trolley, and several vertical tubes 3 are arranged on the pallet 1 of the trolley.

[0011] Such as figure 1 As shown, the height of the vertical pipe 3 is 15-25cm, preferably 20cm. The height of the vertical tube 3 can not be too low or too high, if it is too low, the stability of the paper tube cannot be guaranteed, and if it is too high, it is not conducive to the picking and placing of the paper tube. The vertical pipe 3 can be a steel pipe, which is directly welded on the supporting plate 1 .

[0012] The caster 2 at the bottom of the trolley adopts the universal caster 2, and the universal caster 2 can turn 360 degrees freely, so that it is convenient for the turning and dragging of the trolley to promote. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com