Novel feeding device

A feeding device and a new type of technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unusable, high manufacturing cost, and poor versatility of the vibrating plate, so as to achieve enhanced versatility and control manufacturing costs , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

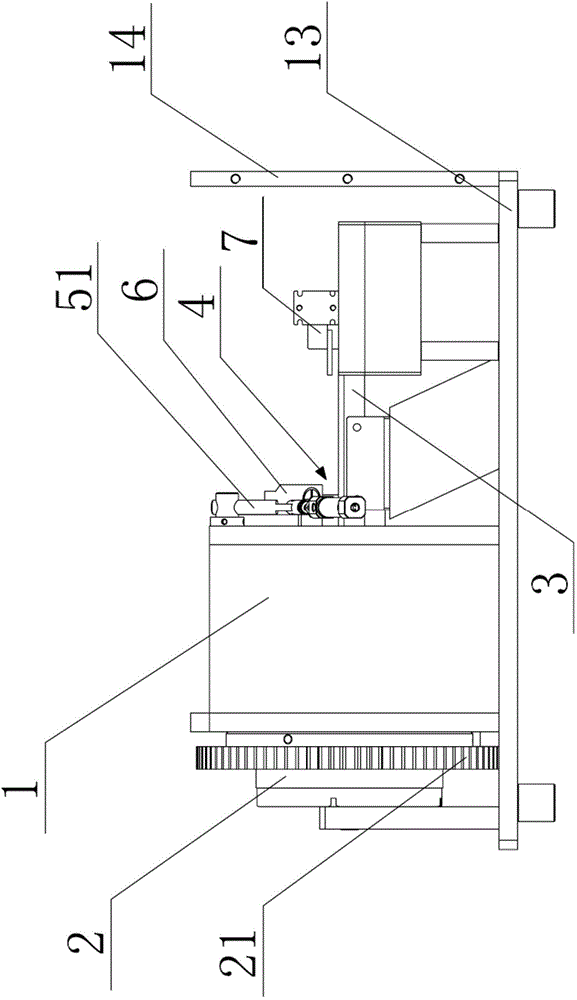

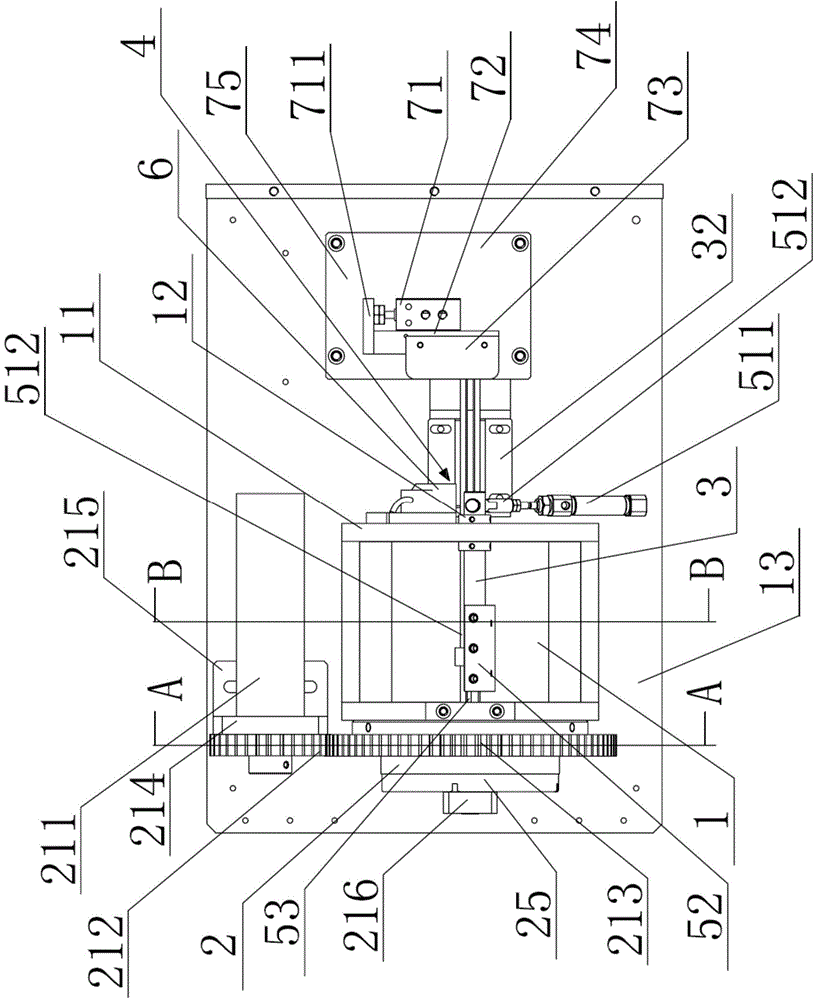

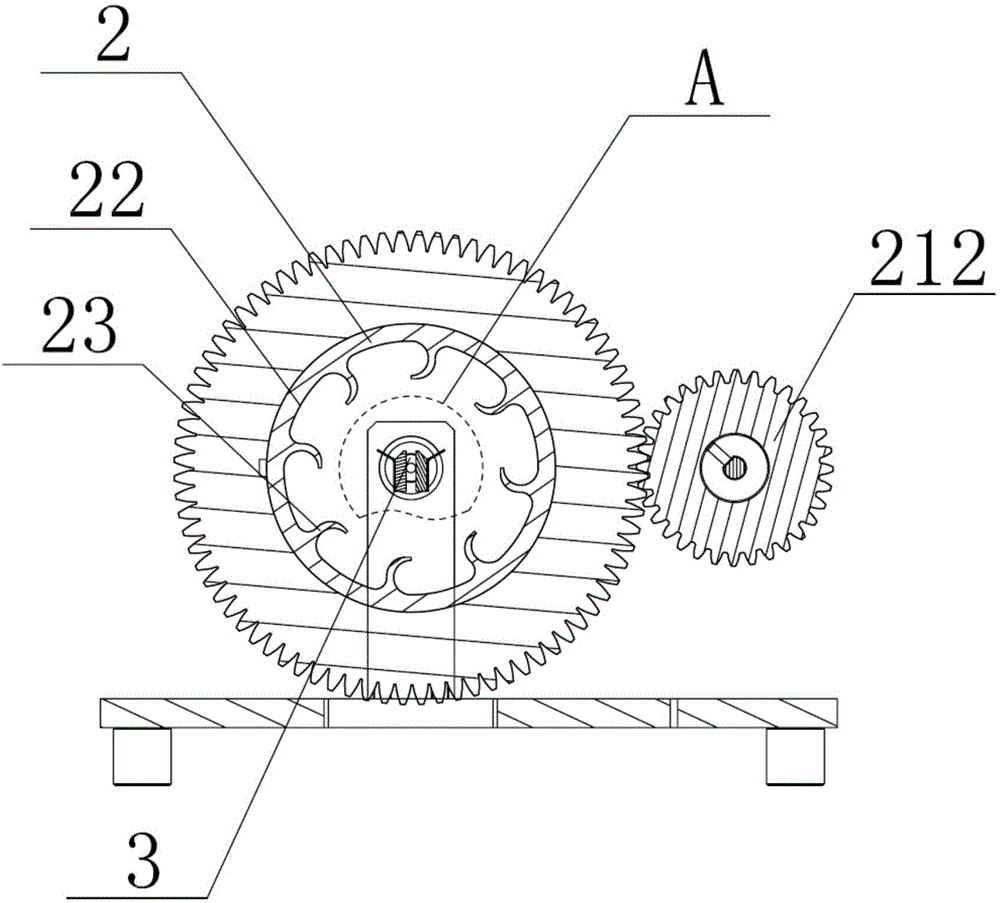

[0047] In order to achieve the purpose of the present invention, as Figure 1-6 As shown, in some of the embodiments of the new feeding device of the present invention, it includes a silo 1, a wheel body 2 and a feeding trough 3; the silo 1 includes a granary baffle 11, a base plate 13 and a side plate 14, which It constitutes the warehouse. Of course, in addition to the granary of this structure, we can also set the two sides in various forms such as spherical, circular, and integral molding, which will not be listed here; the wheel body 2 is tangent to the warehouse 1, the wheel body 2 is driven to rotate by the first drive unit 21, a plurality of blades 23 are arranged in the inner cavity 22 of the wheel body 2, and the inner cavity 22 between the plurality of blades 23 forms a stirring chamber 24, and in order to further stabilize the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com