A coupled symbiotic double-alkali flue gas desulfurization method

A flue gas, double alkali technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high cost and poor desulfurization effect of desulfurizing agents, and achieve lower operating costs, significant environmental protection value and economy. Benefit, the effect of solving water balance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

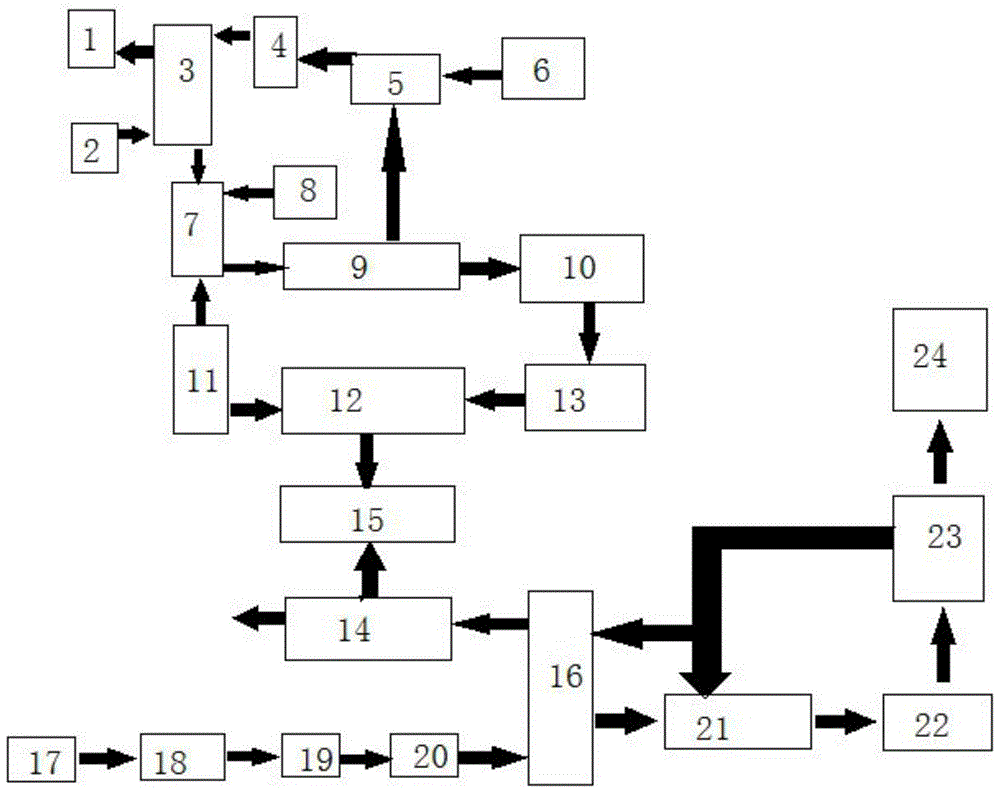

[0023] Such as figure 1 Shown, a kind of coupled symbiotic double-alkali flue gas desulfurization method comprises the following steps:

[0024] (1) Calcium carbide pretreatment: place calcium carbide 17 in crusher 18 and pulverize into powder with particle size≤3mm, and after passing through 130 mesh sieves, place it in storage bin 19 for use;

[0025] (2) Acetylene generation: the calcium carbide powder in the storage bin 19 in step 1) is discharged in the acetylene generator 16 through the buffer bin 20, the water and the calcium carbide powder are 1.1 according to the mass ratio, and the gas phase of the acetylene generator 16 is controlled The temperature of the part is 95°C, the temperature of the liquid phase part is 100°C, and the pressure of the entire acetylene generating device 16 is controlled to be 6kpa, and the stirring speed is adjusted to be 45r / min, and the gas in the acetylene generating device 16 is discharged from the top of the device. into the washing to...

Embodiment 2

[0031] Such as figure 1 Shown, a kind of coupled symbiotic double-alkali flue gas desulfurization method comprises the following steps:

[0032] (1) Calcium carbide pretreatment: place calcium carbide 17 in crusher 18 and pulverize into powder with particle size≤3mm, and after passing through 120 mesh sieves, place it in storage bin 19 for use;

[0033] (2) Acetylene generation: the calcium carbide powder in the storage bin 19 in step 1) is discharged in the acetylene generator 16 through the buffer bin 20, the water and the calcium carbide powder are 0.85 according to the mass ratio, and the gas phase of the acetylene generator 16 is controlled The temperature of the part is 88°C, the temperature of the liquid phase part is 90°C, and the pressure of the entire acetylene generating device 16 is controlled to be 4kpa, and the stirring speed is adjusted to be 30r / min, and the gas in the acetylene generating device 16 is discharged from the top of the device. into the washing to...

Embodiment 3

[0039] Such as figure 1 Shown, a kind of coupled symbiotic double-alkali flue gas desulfurization method comprises the following steps:

[0040] (1) Calcium carbide pretreatment: place calcium carbide 17 in crusher 18 and pulverize into powder with particle size≤3mm, and after passing through 140 mesh sieve, place it in storage bin 19 for use;

[0041] (2) Acetylene generation: the calcium carbide powder in the storage bin 19 in step 1) is discharged in the acetylene generator 16 through the buffer bin 20, the water and the calcium carbide powder are 1.2 according to the mass ratio, and the gas phase of the acetylene generator 16 is controlled The temperature of the part is 100°C, the temperature of the liquid phase part is 110°C, and the pressure of the entire acetylene generating device 16 is controlled to be 7kpa, and the stirring speed is adjusted to be 70r / min, and the gas in the acetylene generating device 16 is discharged from the top of the device. into the washing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com