Coir rope uncoiling crusher

A crusher and crushing mechanism technology, applied in the field of crushers and brown rope de-rotating crushers, can solve the problems of low work efficiency, inability to meet mass production, high labor intensity, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

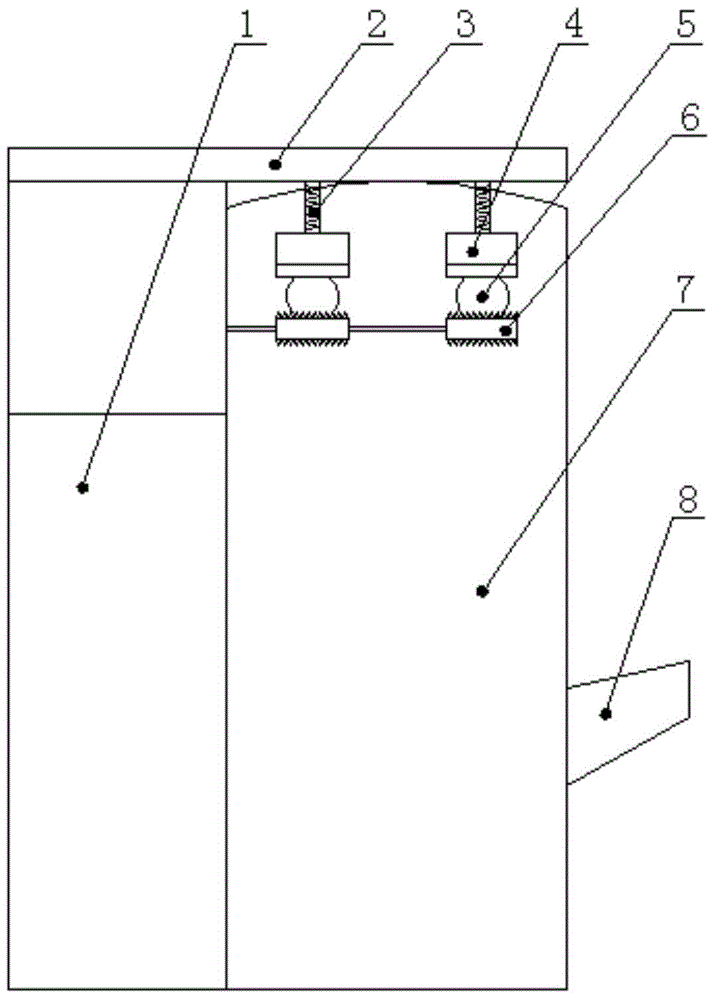

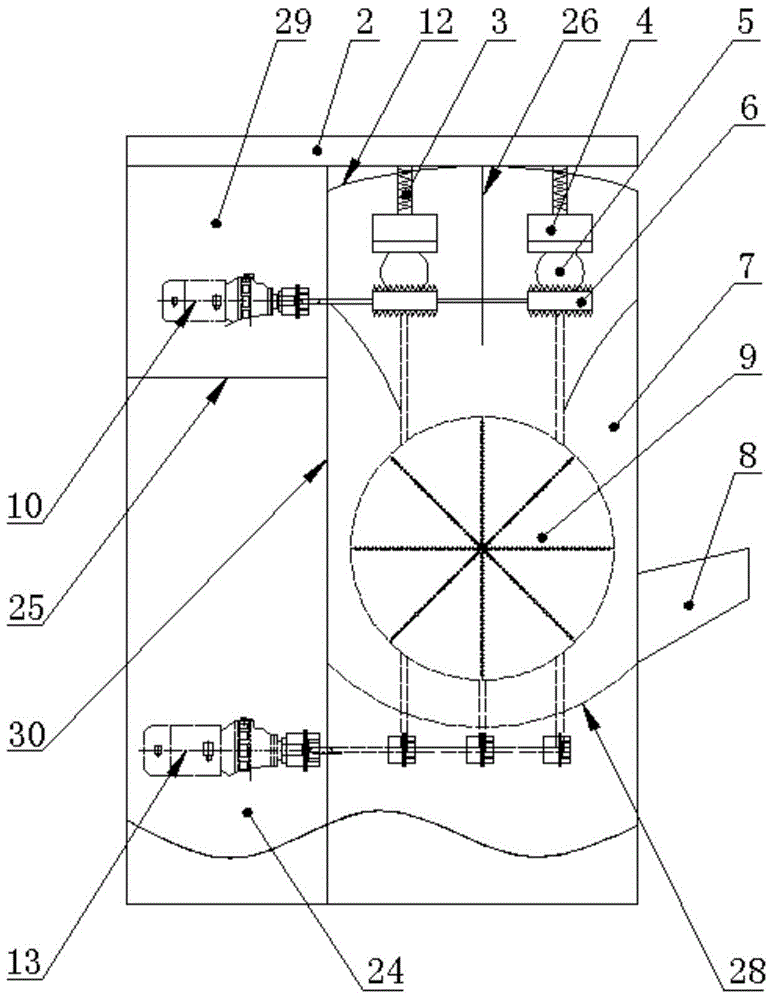

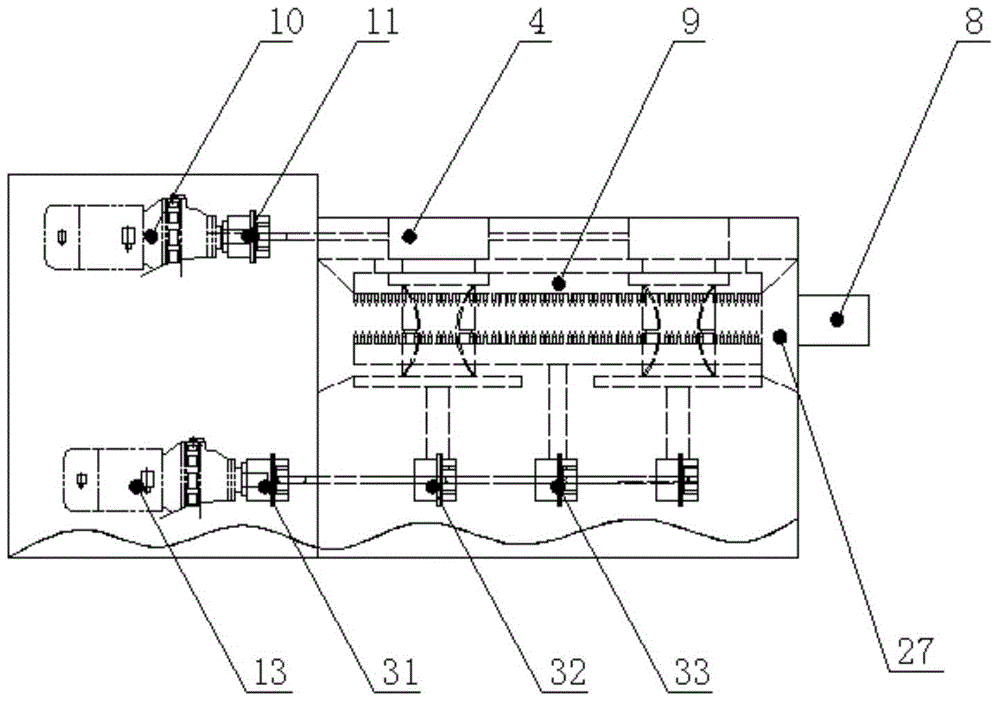

[0027] A palm rope detwisting crusher, which is composed of a cabinet, a feeding mechanism, a decomposition mechanism, and a discharge port; the cabinet is composed of a motor cabin 1 and a decomposition cabin 7, and the motor cabin and the decomposition cabin pass through the central guard plate that runs through the machine body longitudinally 30 apart; the feed mechanism and the discharge port 8 are respectively installed on the top and the side of the decomposition cabin outer wall, the feed mechanism is made up of the feed port 5, the briquetting block 4 and the feed roll 6, the briquetting block and the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com