printing press

A technology of printing presses and gears, applied in printing presses, printing, rotary printing presses, etc., can solve problems such as increasing work preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

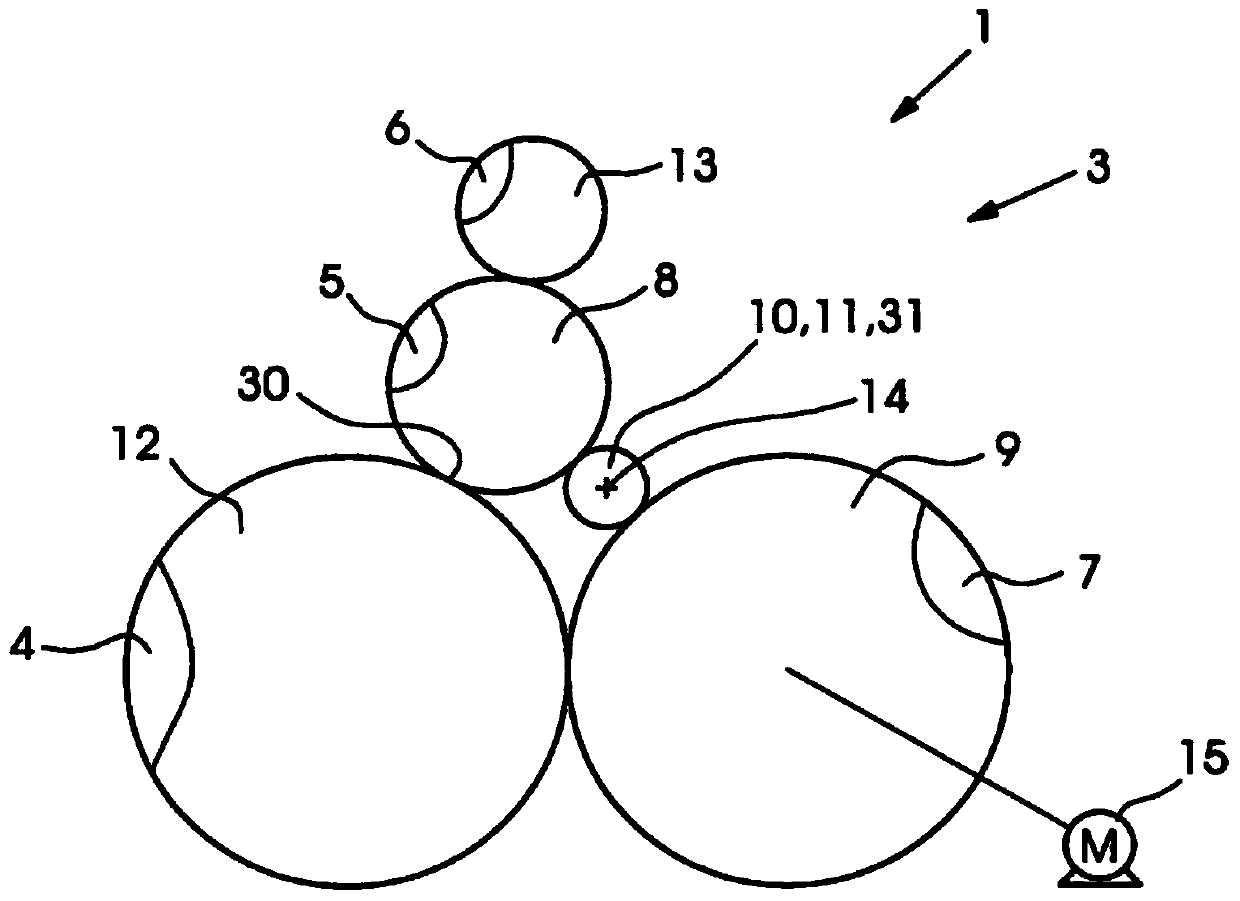

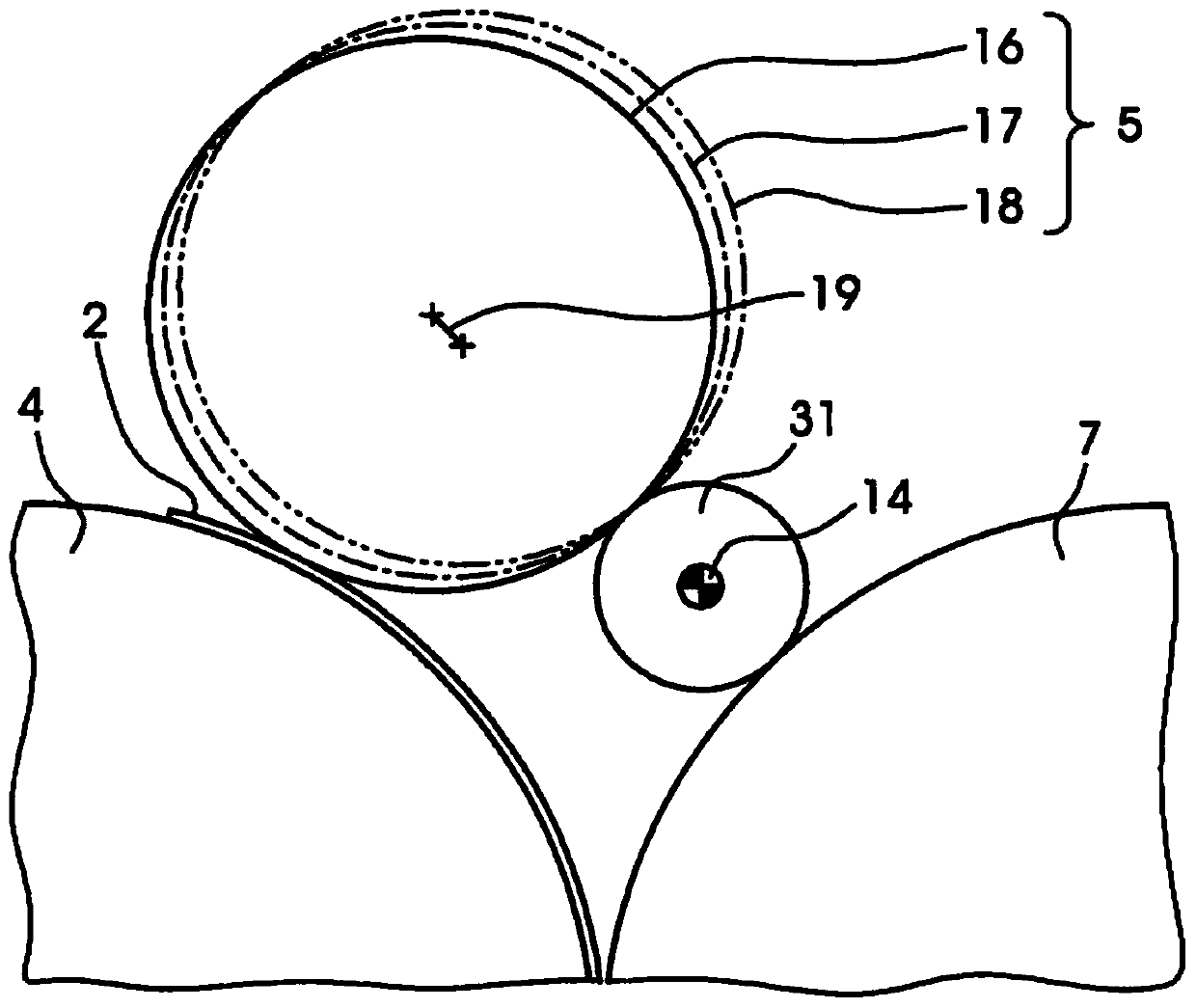

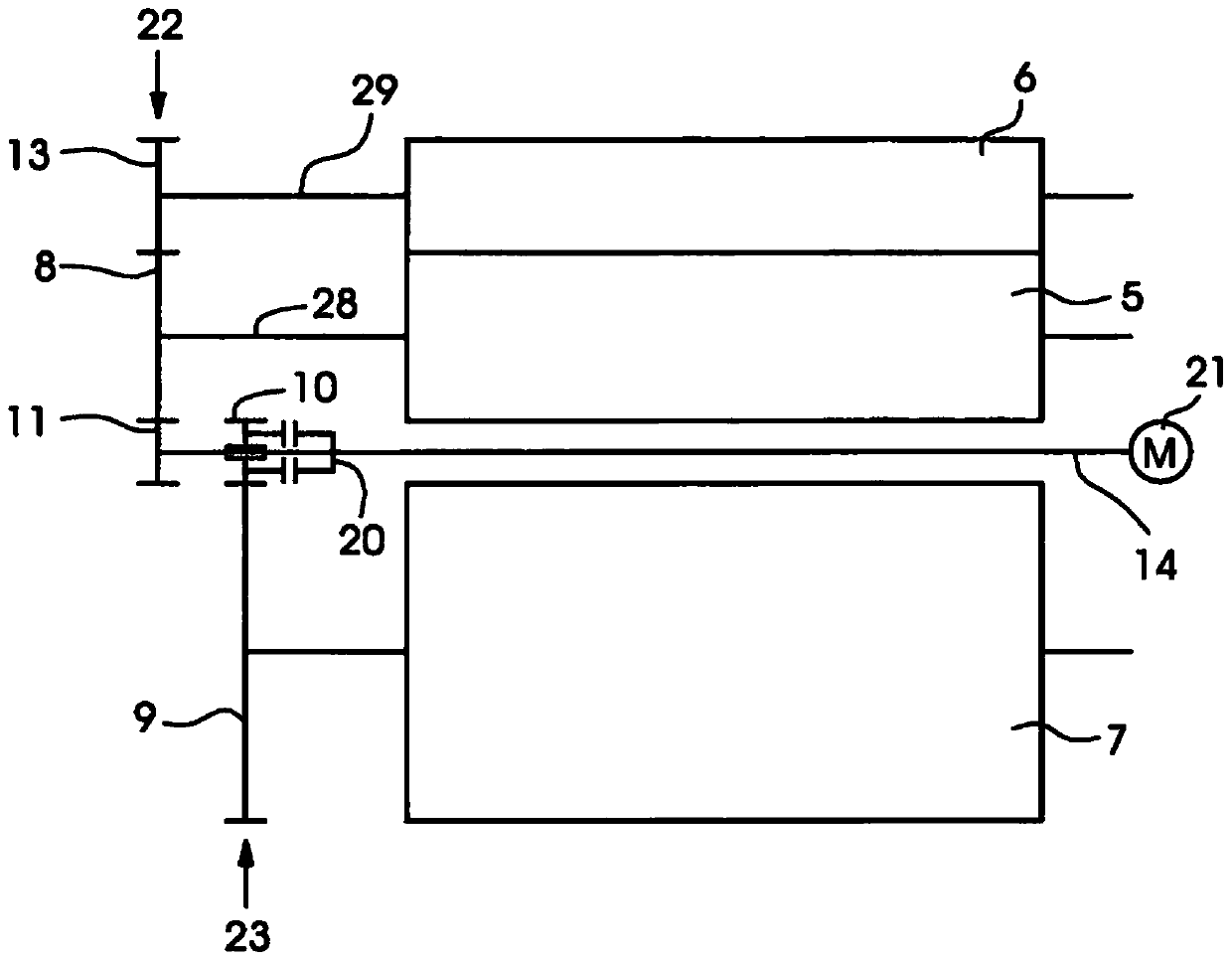

[0029] exist figure 1 A printing press 1 for offset lithographic printing on sheets 2 is shown partially in the middle. A varnishing unit 3 for varnishing a sheet 2 printed in an offset printing unit is shown in this detail. The varnishing unit 3 comprises an impression cylinder 4 for transporting the sheets 2 and an application cylinder 5 for applying varnish to the respective transported sheets 2 . During varnishing, the embossing cylinder 4 and the application cylinder 5 together form an embossing nip 30 in which a coating liquid (varnish) is transferred from the application cylinder 5 to the conveyed sheet 2 . The anilox roller 6 rests against the application cylinder 5 and supplies the varnish to this application cylinder. In the sheet transport arrangement, a sheet transport drum 7 is arranged upstream of the impression cylinder 4 , which feeds the sheets 2 one after the other onto the impression cylinder 4 . The impression cylinder 4 and the sheet transfer drum 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com