All-permeable brick mold

A technology of permeable bricks and moulds, applied in the directions of moulds, mould separation devices, mould auxiliary parts, etc., can solve the problems of incapable and incomplete permeable pavement, cement mortar connection layer does not have water permeable function, etc., to ensure the quality of brick body, reduce The effect of floor space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

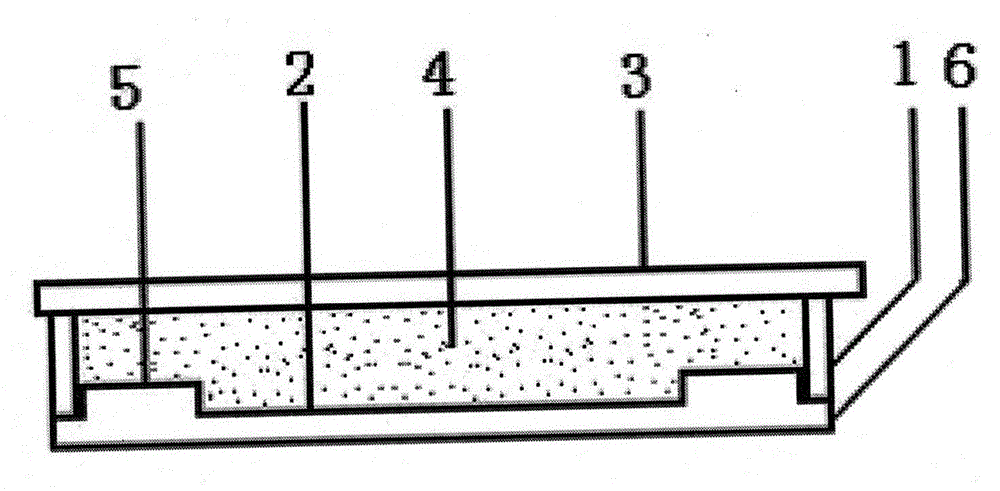

[0012] In the embodiment of the accompanying drawings, the present invention is composed of a side formwork 1, a bottom plate 2, and a supporting plate 3. The side formwork 1 is square or rectangular according to the shape requirements of the brick body 4. The inside of the side formwork 1 The length of the side is the same as that of the outer side of the brick body 4, and the height is equal to the height of the brick body 4.

[0013] Bottom plate 2 is the forming plate of brick body 4 protruding part and mortar connecting groove, and bottom plate 2 has protruding platform 5 and positioning platform 6, and the specification of protruding platform 5 is equal to the specification of mortar connecting groove, and the outer edge length of protruding platform 5 is equal to brick body 4, the outer length of the bottom plate 2 is the same as the outer length of the side formwork 1, the inner length of the side formwork 1 is the same as the outer length of the protruding platform 5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com