A calibration device and calibration method for the relationship between pretightening force and pretightening torque

A calibration device and pre-tightening force technology, applied to measuring devices, force/torque/work measuring instruments, and measuring torque/torsion force during tightening, can solve problems such as wire breakage, calibration data, discontinuity, and easy entanglement of wires , to achieve the real effect of the calibration result

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

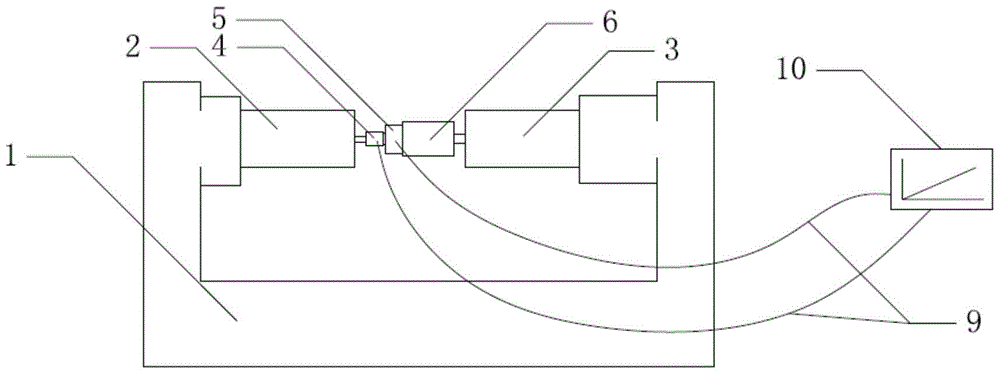

[0025] This embodiment provides a device for calibrating the relationship between pre-tightening force and pre-tightening torque, which is mainly used for calibrating the relationship between pre-tightening force and pre-tightening torque of separation nuts. Its structure is as follows: figure 1 As shown, it includes a device 1 capable of providing a torsional load, a torsional force sensor sleeve 4, a pressure sensor tooling 5, a separation nut sleeve 6 and a data processing device 10; the device 1 capable of providing a torsional load is an existing device, including The equipment body, the torsion end fixture 2 and the fixed end fixture 3, the equipment body includes a bottom plate and two side plates parallel to each other, the torsion end fixture 2 and the fixed end fixture 3 are respectively installed on the inner side of the two side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com