Shovel loading control system and shovel loading control method for loader

A control system and loader technology, applied in the direction of earth movers/shovels, construction, etc., can solve the problems of aging handles or switches, inability to perform quick operation shovel loading, affecting work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

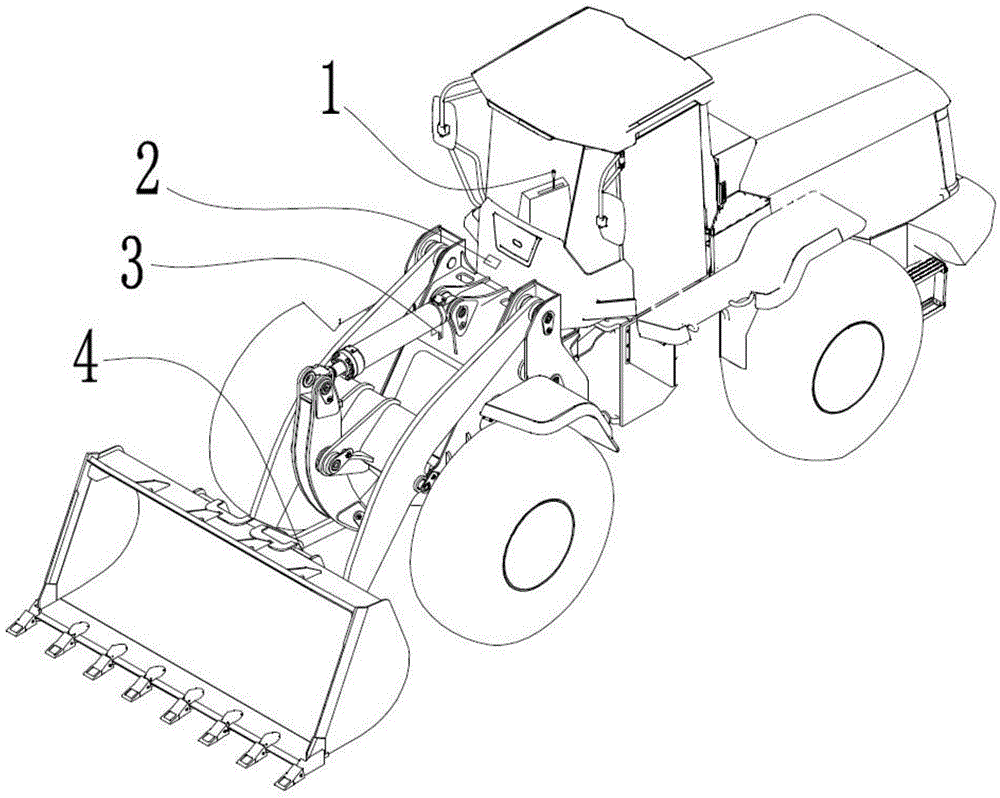

[0021] Such as figure 1 figure 2 As shown, the shovel loading control system of the loader in this embodiment includes a bucket, a lifting device hinged with the bucket for lifting the bucket, a rotary bucket cylinder that pushes the bucket to rotate around the front end of the lifting device, and the lifting device Including the boom and the boom cylinder for lifting the boom, the bucket is hinged at the front end of the boom, and the bucket cylinder pulls the bucket to turn back and forth around the front end of the boom through the linkage mechanism. An electric control valve 3 for controlling the action of the bucket cylinder is installed on the driving oil circuit of the bucket cylinder, the electronic control unit 2 is connected to the electric control valve 3, and the control switch 1 and the bucket bucket angle sensor 4 are connected to the electronic control unit 2 , wherein the bucket rotation angle sensor 4 is used to detect the rotation angle of the bucket so as ...

Embodiment 2

[0023] Such as Figure 3 to Figure 5 As shown, the shovel loading control system of the loader in this embodiment includes a bucket, a lifting device hinged with the bucket for lifting the bucket, a rotary bucket cylinder that pushes the bucket to rotate around the front end of the lifting device, and the lifting device Including the boom and the boom cylinder for lifting the boom, the bucket is hinged at the front end of the boom, and the bucket cylinder pulls the bucket to turn back and forth around the front end of the boom through the linkage mechanism. An electric control valve 3 for controlling the movement of the bucket cylinder is installed on the driving oil circuit of the bucket cylinder. The electronic control unit 2 is connected to the electric control valve 3. The boom rotation angle sensor 6, bucket bucket rotation angle sensor 4, The pressure sensor 5 and the like are connected to the electronic control unit 2, wherein the bucket rotation angle sensor 4 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com