Pneumatic ejector pin clamp

A thimble, air pressure technology, applied in the field of workpiece accessories, can solve the problems of affecting the clamping effect, easy to shake up and down, insufficient clamping force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

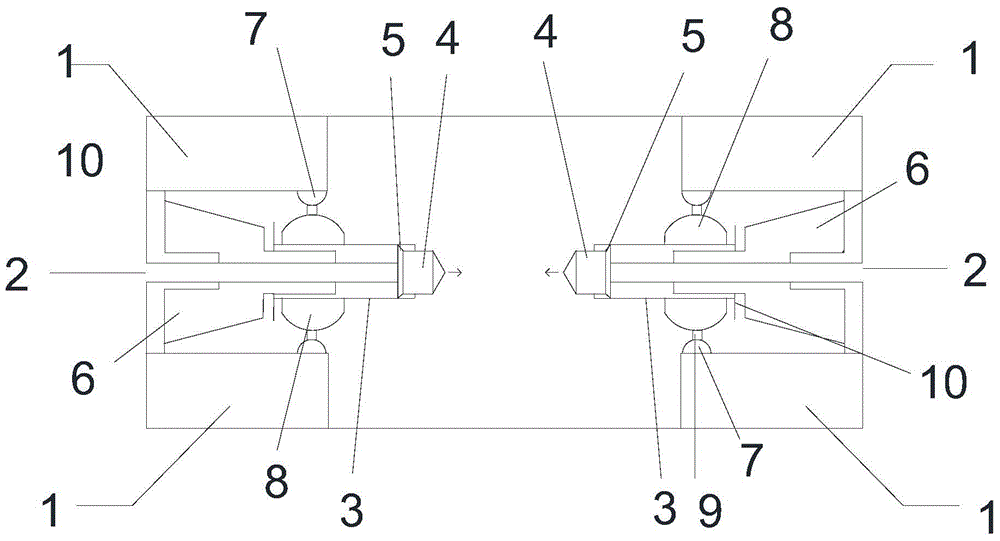

[0011] like figure 1 As shown, the air pressure thimble clamp includes four fixed blocks 1 located at the top corners, an air pressure thimble is arranged between the upper and lower two fixed blocks 1, and the air pressure thimble includes air passages 2 on both sides, The air passage 2 communicates with the cylinder 3, and the other side of the cylinder 3 is provided with a collet 4, and the collet 4 is connected in the cylinder 3 through an airtight ring 5, and the outer periphery of the air pressure thimble is provided with The expansion ring 6, the section of the expansion ring 6 is trapezoidal, and part of the upper bottom surface of the trapezoidal section extends into the cylinder 3.

[0012] According to the above structure, the collet moves back and forth through the air pressure in the air circuit in the cylinder. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com