Automatic rotary indexing mechanism of tightening machine

A technology of automatic rotation and indexing mechanism, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low operation accuracy, inability to meet the requirements of high-beat operation, etc., achieve accurate indexing, simple structure, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

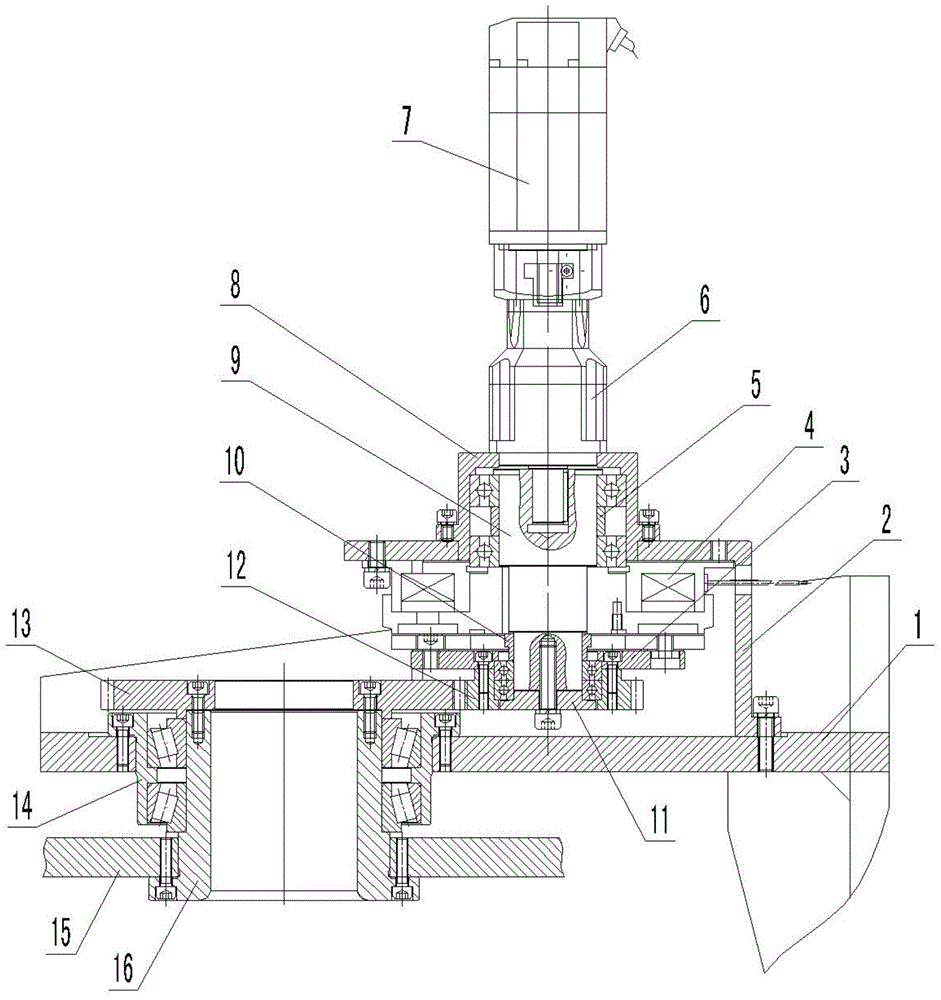

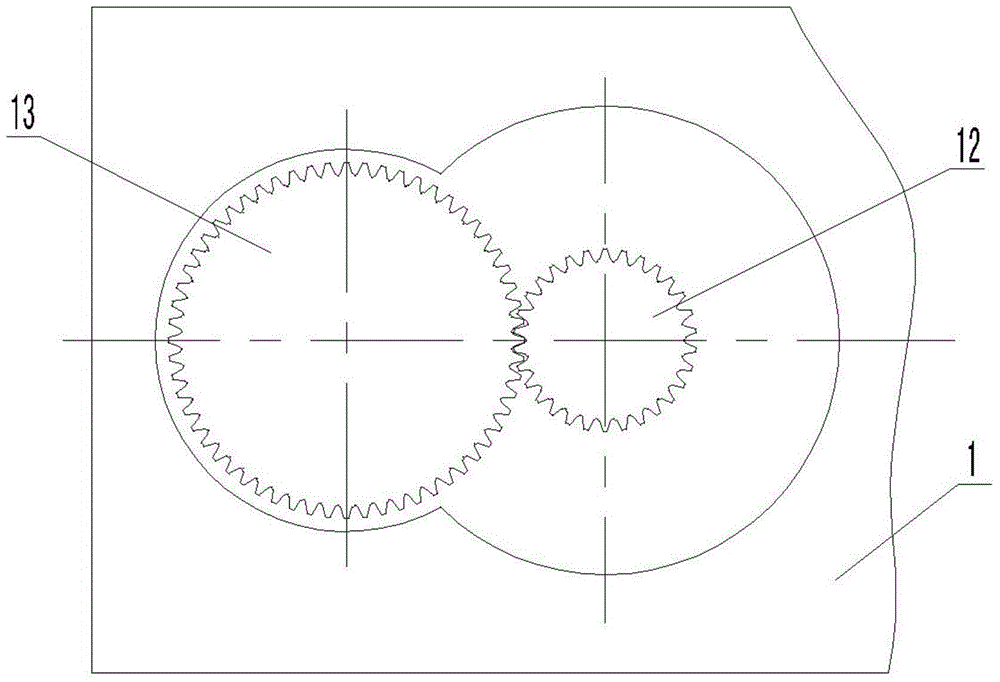

[0020] see figure 1 with figure 2 , the structural form of the automatic rotation indexing mechanism of the screwing machine in this embodiment is: a pair of driving gear 12 and driven gear 13 meshed with each other are set, and a servo drive mechanism is set for driving the driving gear 12 with the central point of the driving gear 12 "O" rotates as the center of rotation, and the driven gear 13 takes the center point "O" as the center and rotates around the driving gear 12 according to the set index; the upper rotating plate 15 is fixed to the driven gear 13 through the upper rotating shaft 16 connected to realize the indexing function of the driven gear 13 together with the upper rotating plate 15 and the upper rotating shaft 16.

[0021] In the specific implementation, the corresponding structure is set as:

[0022] The output end of the servo motor 7 is connected with the input end of the planetary reducer 6, and the servo motor 7 and the planetary reducer 6 are integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com