H-girder welding deformation control device

A control device and welding deformation technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of welding angle deformation of H-shaped beams, and achieve the effect of reducing residual stress, avoiding influence, and reasonable welding sequence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

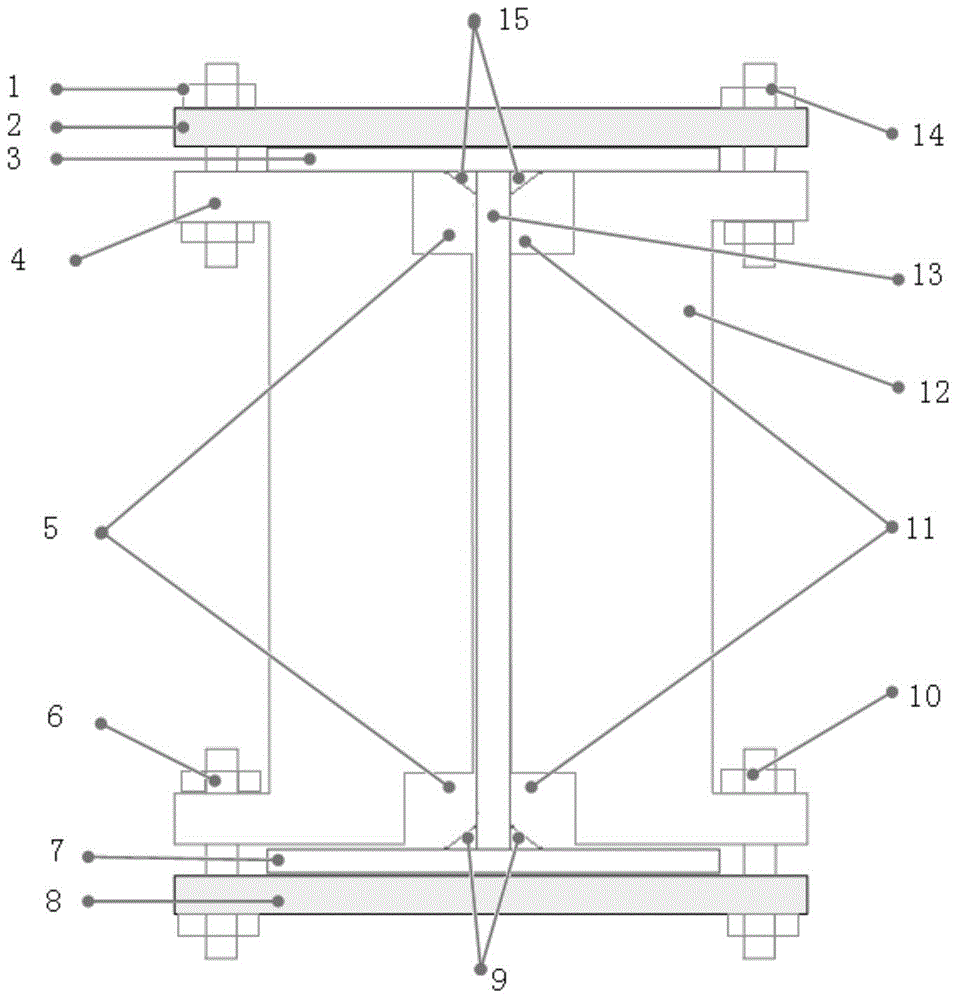

[0042] An H-shaped beam welding deformation control device, its structure is as follows figure 1 As shown, it mainly includes an upper pressure plate 2 connected to the upper surface of the upper wing plate 3 , a left pressure plate 4 and a right pressure plate 12 symmetrically connected to both sides of the web 13 , and a lower pressure plate 8 connected to the lower surface of the lower wing plate 7 . The left pressure plate 4 and the right pressure plate 12 are respectively connected with the upper pressure plate 2 and the lower pressure plate 8 through the upper left screw 1, the lower left screw 6, the upper right screw 14 and the lower right screw 10, thereby controlling the position of the upper wing plate 3 and the lower wing plate 7 during welding No angular deformation will occur, and the inner sides of the left pressing plate 4 and the right pressing plate 12 are arranged on the left and right sides of the web 13 . A left welding process hole 5 and a right welding p...

Embodiment 2

[0055] The above-mentioned device is used to control the welding deformation of the H-shaped beam. Web size: length 1200mm, height 144mm, 6.0mm. Welding method: manual welding, no virtual welding exists. Under the action of the deformation control device, the geometric dimensions of the H-shaped girder are basically unchanged.

Embodiment 3

[0057] H-beam-QSTE700 welding deformation control

[0058] The above-mentioned device is used to control the welding deformation of the H-shaped beam. Web size: length 400mm, height 76mm, 4.0mm. Welding method: manual welding, no virtual welding exists. Under the action of the deformation control device, the welding deformation of the H-shaped beam composed of high-strength steel plates of 700 MPa is well controlled.

[0059] The patented method and device of the present invention can be used to realize the control of the H-shaped beam in the welding deformation process, ensure the size and assembly accuracy of the H-shaped beam after welding, reduce unnecessary post-weld straightening procedures, and can be widely used in similar structures. In welding deformation control, it has important reference and application value for welding auxiliary positioning and precision assurance of large structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com