Automatic die changing device of bending machine

An automatic die changing and bending machine technology, applied in the field of bending machines, can solve the problems of affecting the service life of the bending machine, bending and deformation of the rotating shaft, and occupying a large space, so as to achieve a small occupied space and improve the efficiency of die changing. Efficient, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

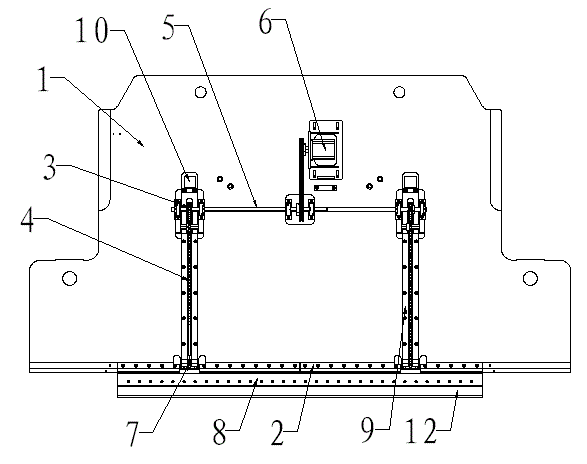

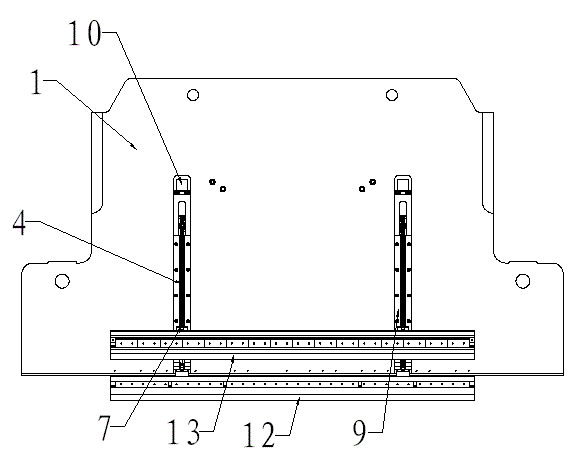

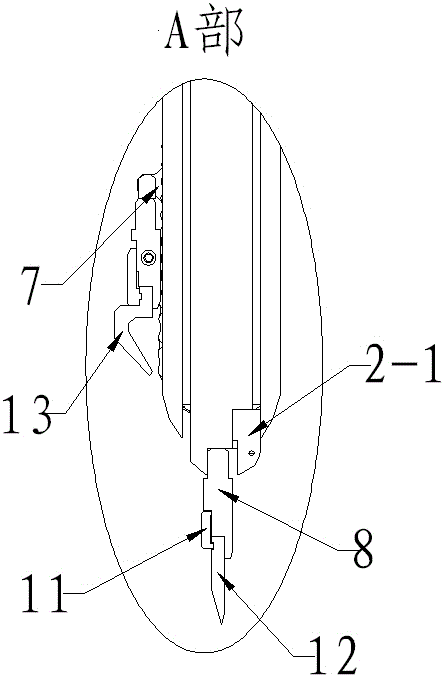

[0023] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

[0024] Such as Figure 1-Figure 4 Shown: an automatic mold changing device for a bending machine, including a slider 1, the lower end of the slider 1 is provided with a clamping device 2; two sets of chain transmission devices are installed in parallel on the slider 1, so The chain transmission device includes a sprocket 3 and an endless chain 4 meshed with the sprocket 3. The two sprockets 3 are connected to the drive motor 6 through a horizontal rotating shaft 5. The endless chain 4 vertically surrounds the slide Outside the block 1, the endless chain 4 is provided with two connecting parts 7, the connecting parts 7 are hinged with the mold handle 8, and the sliding block 1 is provided with a lifting guide rail 9, and the connecting parts 7 are slidingly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com