Compositions containing purified non-Hevea rubber and related purification methods

A non-Hevea plant, non-Hevea technology for use in compositions containing purified non-Hevea rubber and related purification fields, capable of solving complex and necessary problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0090] Example 1 (Purification of rubber from TKS plant matter)

[0091] As described in more detail herein, rubber was isolated and purified from samples of TKS harvested plant matter according to the following procedure. Crude TKS harvested plant matter was prepared by adding the harvested plant matter and toluene to an Erlenmeyer flask (the flask was stoppered after material addition to minimize any evaporation of the solvent) with stirring. Add to toluene at room temperature (plant matter added at a weight / volume ratio of 1:20 or 100 g harvested plant matter / 2000 mL toluene). TKS Harvested plant matter consists primarily of root material from rubber grass plants (the plants were about 2-3 years old at the time of harvesting) that are harvested and washed thoroughly with water to remove all visible dirt , and dry. (The washed and dried roots have been pebble-milled, sieved, and separated by a water-based flotation process to separate most of the cellulosic plant materia...

example 2

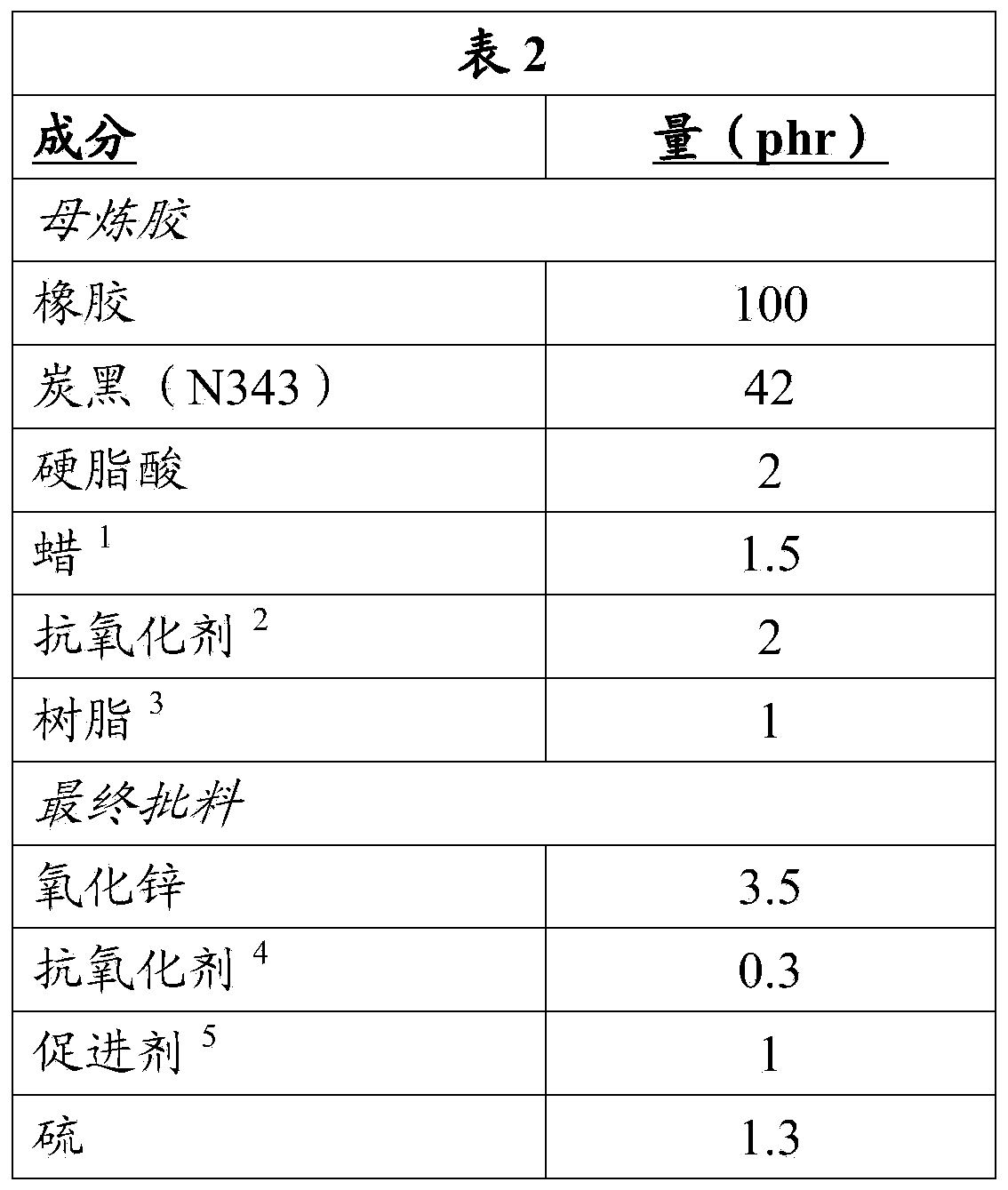

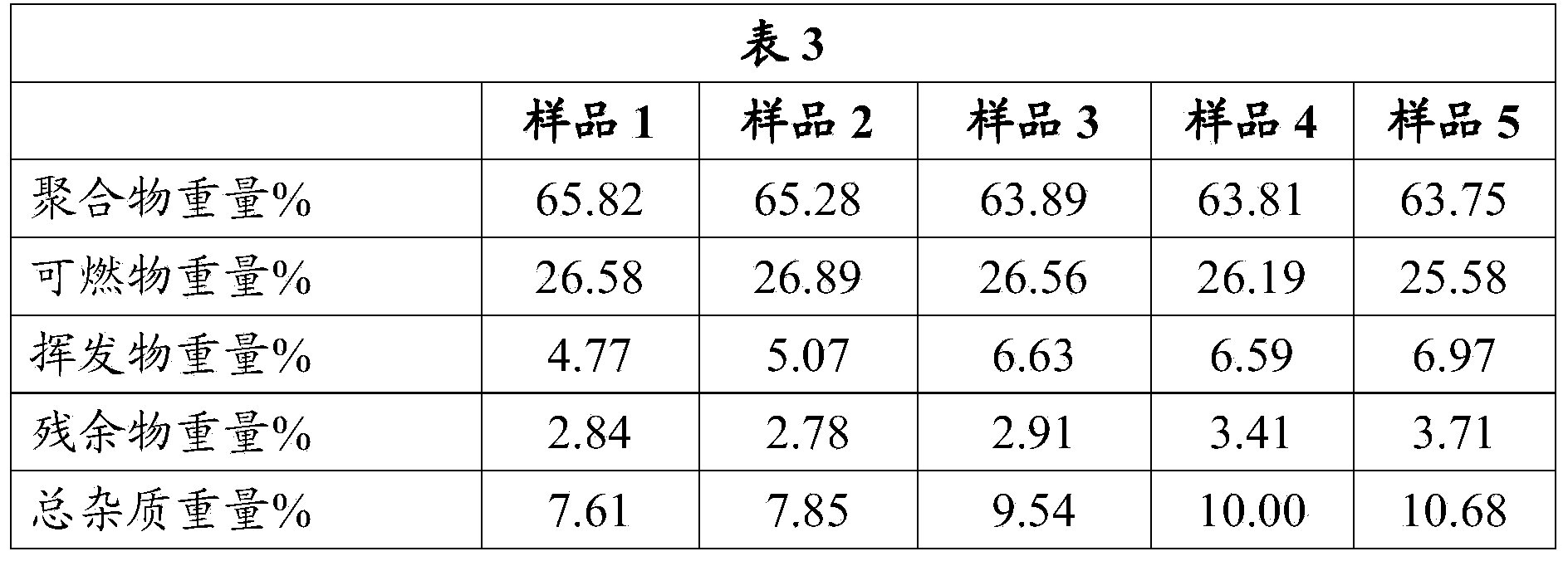

[0094] Example 2 - Preparation of Rubber Compound Using TKS Source Natural Rubber

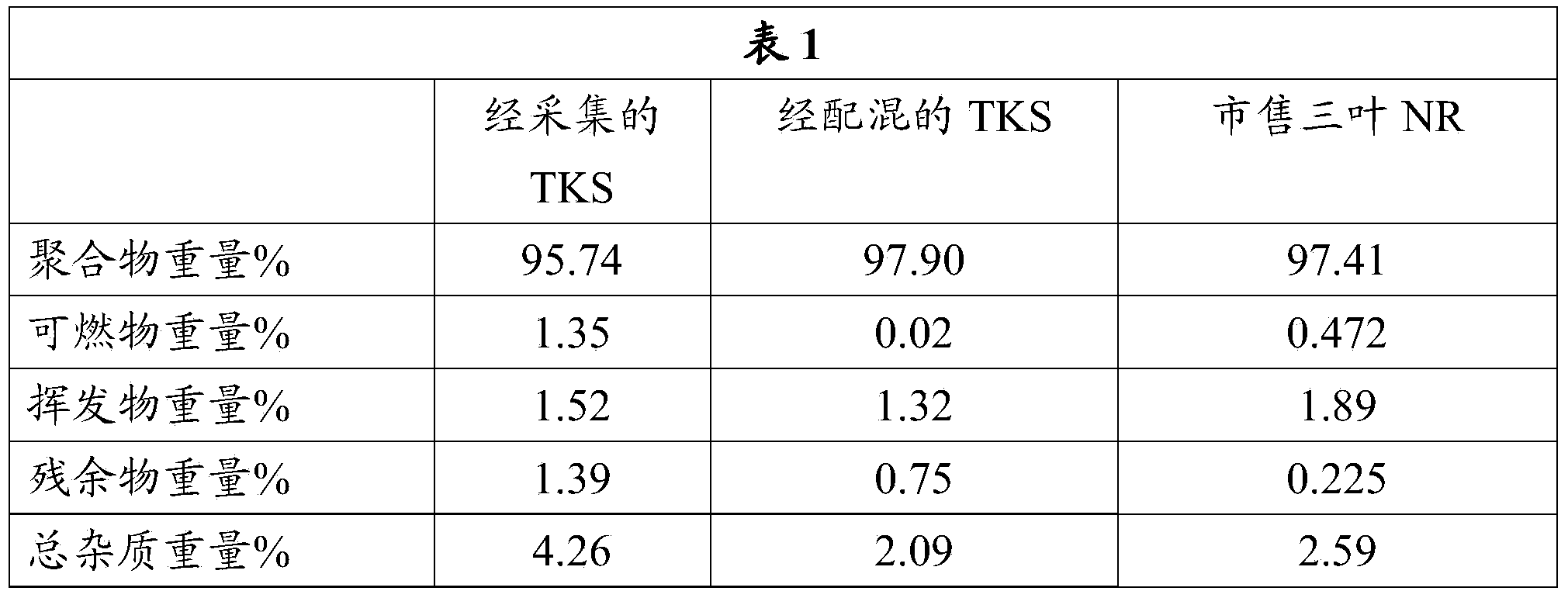

[0095] To evaluate the effect of impurity levels on rubber compounds, rubber compounds were prepared using purified TKS source natural rubber with different impurity levels. (The abbreviation "TKS" is used to refer to rubber grass.) A rubber compound containing a commercially available Hevea source natural rubber was used as a control. The TKS source natural rubber denoted below as "Compounded TKS" was obtained from a sample of harvested TKS purified using the procedure described in Example 1 above. The TKS source natural rubber denoted below as "harvested TKS" was a sample provided by the Ohio State University Agricultural Research and Development Center; methods used to purify the harvested TKS included passing water Flotation Pebble milling, sieving and separation (more precise details not available). Each natural rubber source was found to contain the amounts listed in Table 1 below. R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com