A construction method for the support of multi-arch tunnel without chamber and large pipe shed

A technology for multi-arch tunnels and construction methods, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as difficulty in switching construction steps, increased construction risk levels, and increased construction difficulty, so as to ensure operational comfort and reduce costs. The effect of small expansion of earth volume and reduction of construction excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0036] A construction method for supporting a multi-arch tunnel body without a large pipe shed, comprising the following steps:

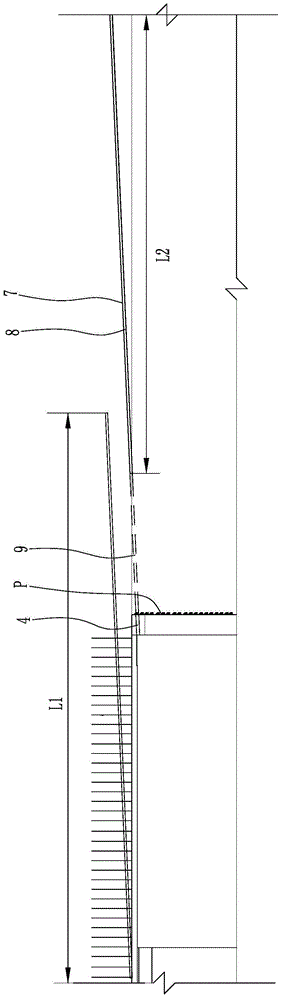

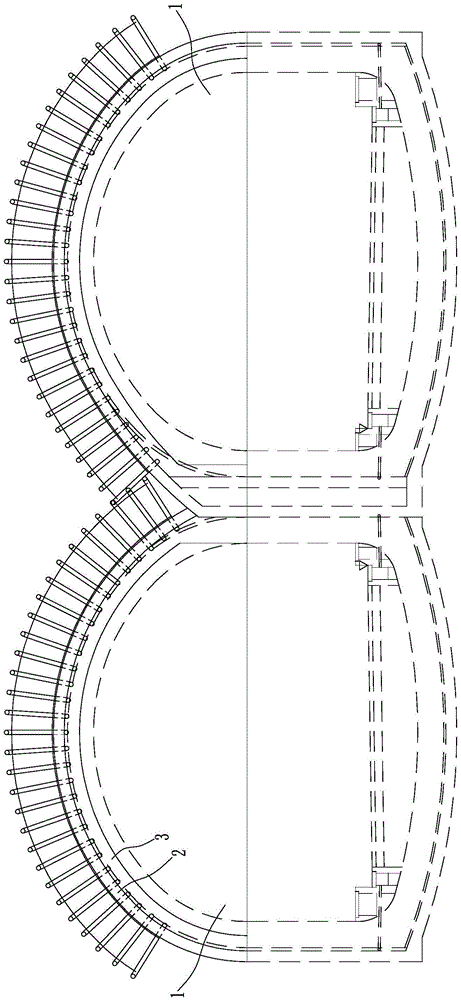

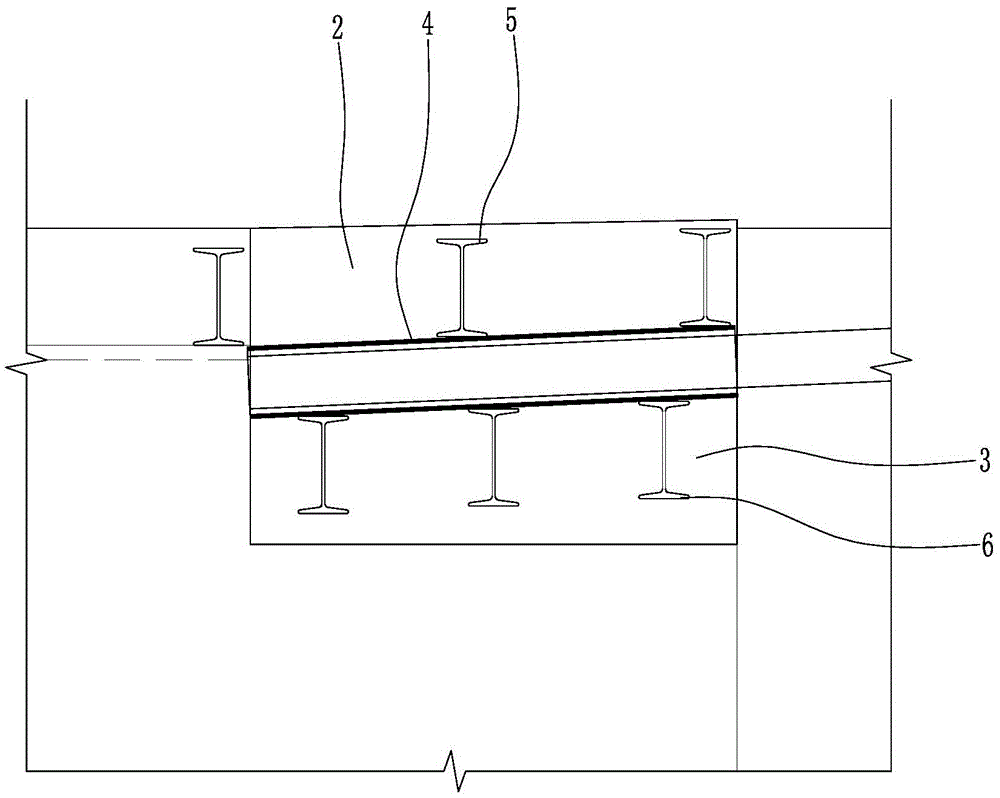

[0037] 1) Build a composite guide wall and install a guide pipe 4 at the face P of two tunnels 1 arranged side by side: the composite guide wall includes a sprayed concrete layer 2 and a poured concrete layer 3, and the sprayed concrete layer 2 The pouring concrete layer 3 is distributed along the arc profile of the top of the tunnel 1, and the pouring concrete layer 3 is located inside the sprayed concrete layer 2; the initial support steel frame 5 is arranged in the sprayed concrete layer 2, and the initial support steel frame 5 is The frame structure is composed of parallel I-beams and steel bars connected between two adjacent I-beams; a temporary steel frame 6 is arranged in the pouring concrete layer 3, and the temporary steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com