Compressed packer rubber barrel with spacer ring combined spring shoulder pad

A compression packer and composite spring technology, which is used in sealing/packing, wellbore/well components, earth-moving drilling, etc. Recycling and other issues to achieve the effect of meeting high temperature, high pressure and deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

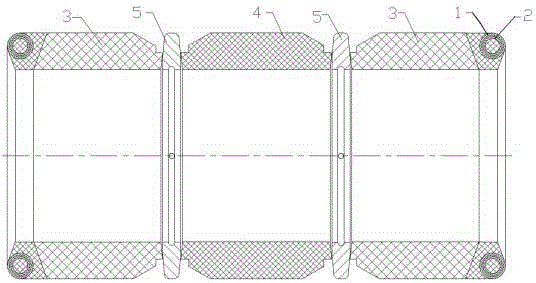

[0024] like image 3 The rubber sleeve of a composite spring shoulder compression packer with a spacer ring shown includes a rubber sleeve body, which is a combined structure of three rubber sleeves, including two side rubber sleeves 3 and a middle rubber sleeve 4. The middle rubber tube 4 is located between the two side rubber tubes 3, and the two ends of the middle rubber tube 4 are separated from the side rubber tubes 3 by a spacer ring 5, and the side rubber tube 3 and the middle rubber tube 4 are respectively It is in close contact with the spacer ring 5; the structure of the rubber cylinder body is a combined structure of three rubber cylinders with spacers, and the structure of the rubber cylinder is a three-stage sealing structure. When working, even if the single-stage seal fails, the other two sections can also work. To effectively seal the role. The shoulders of the two side rubber tubes 3 are respectively provided with multi-layer spirals for protecting the should...

Embodiment 2

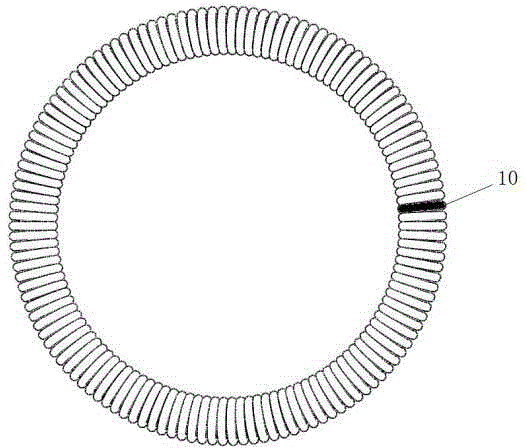

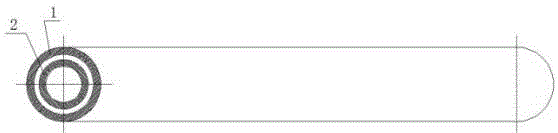

[0026] On the basis of Embodiment 1, the multi-layer coil spring ring includes an outer coil spring ring 1 and an inner coil spring ring 2 sleeved in the outer coil spring ring 1, as figure 1 , figure 2 As shown, its structure is that a small cylindrical helical spring is placed in a large helical spring, and the head and tail ends of the inner and outer helical springs are respectively welded by a special process to form a ring (welding points 10 such as figure 1 shown in ), the ring can radially expand and contract; the number of inner helical spring rings 2 in this embodiment is at least one. The multi-layer helical spring ring is inlaid on the shoulder of the side rubber tube 3 and vulcanized into one with the side rubber tube 3, the rubber penetrates into the inside of the spring, and the spring plays the role of strengthening the rubber strength, as image 3 shown. The multi-layer helical spring ring can expand with the expansion of the rubber tube, and bear the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com