Connecting structure for motor and circuit board in flat sewing machine control device

A control device and connection structure technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of low installation efficiency, troublesome connection between motor and circuit board, etc., and achieve the effect of improving installation efficiency and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

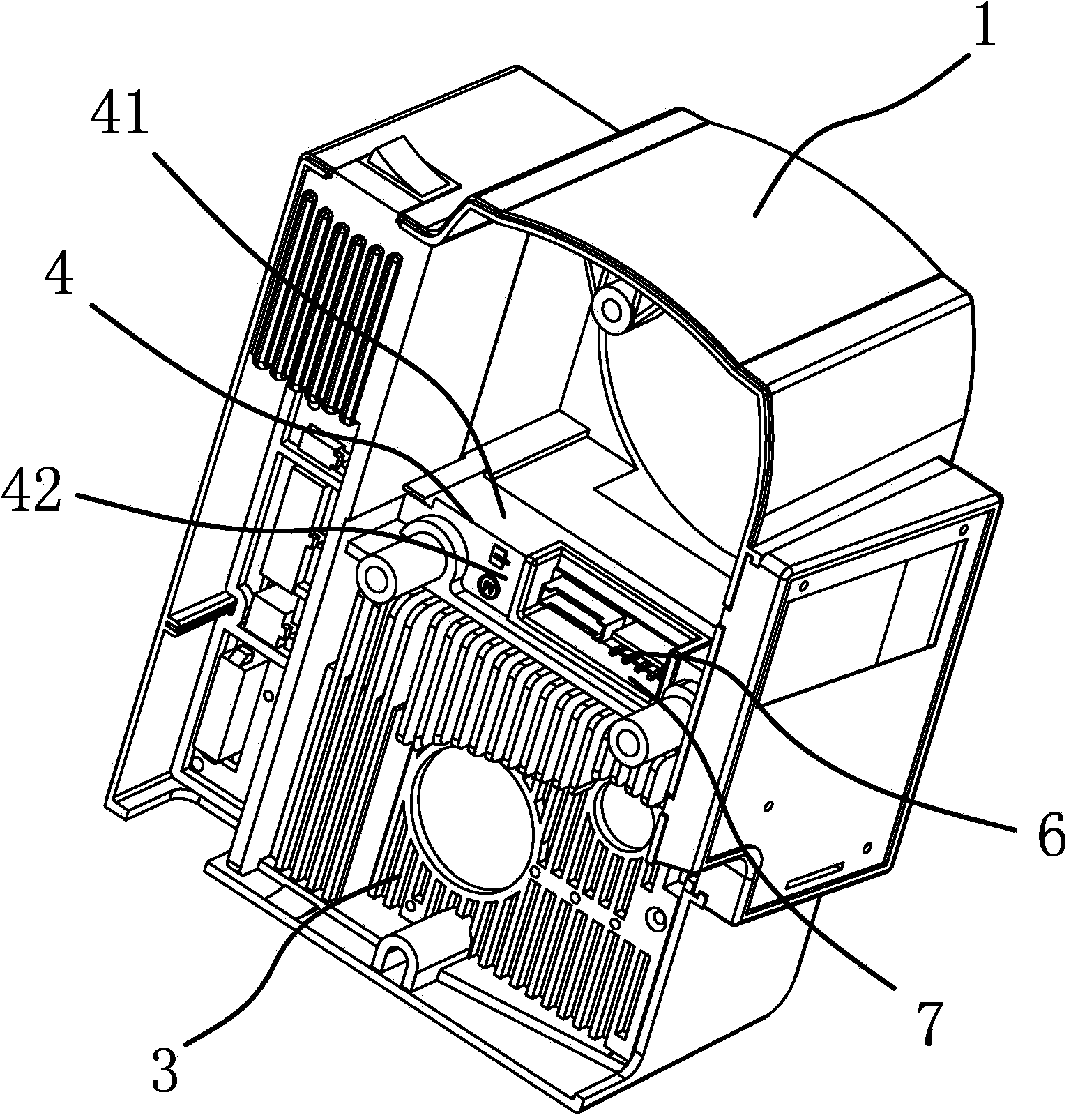

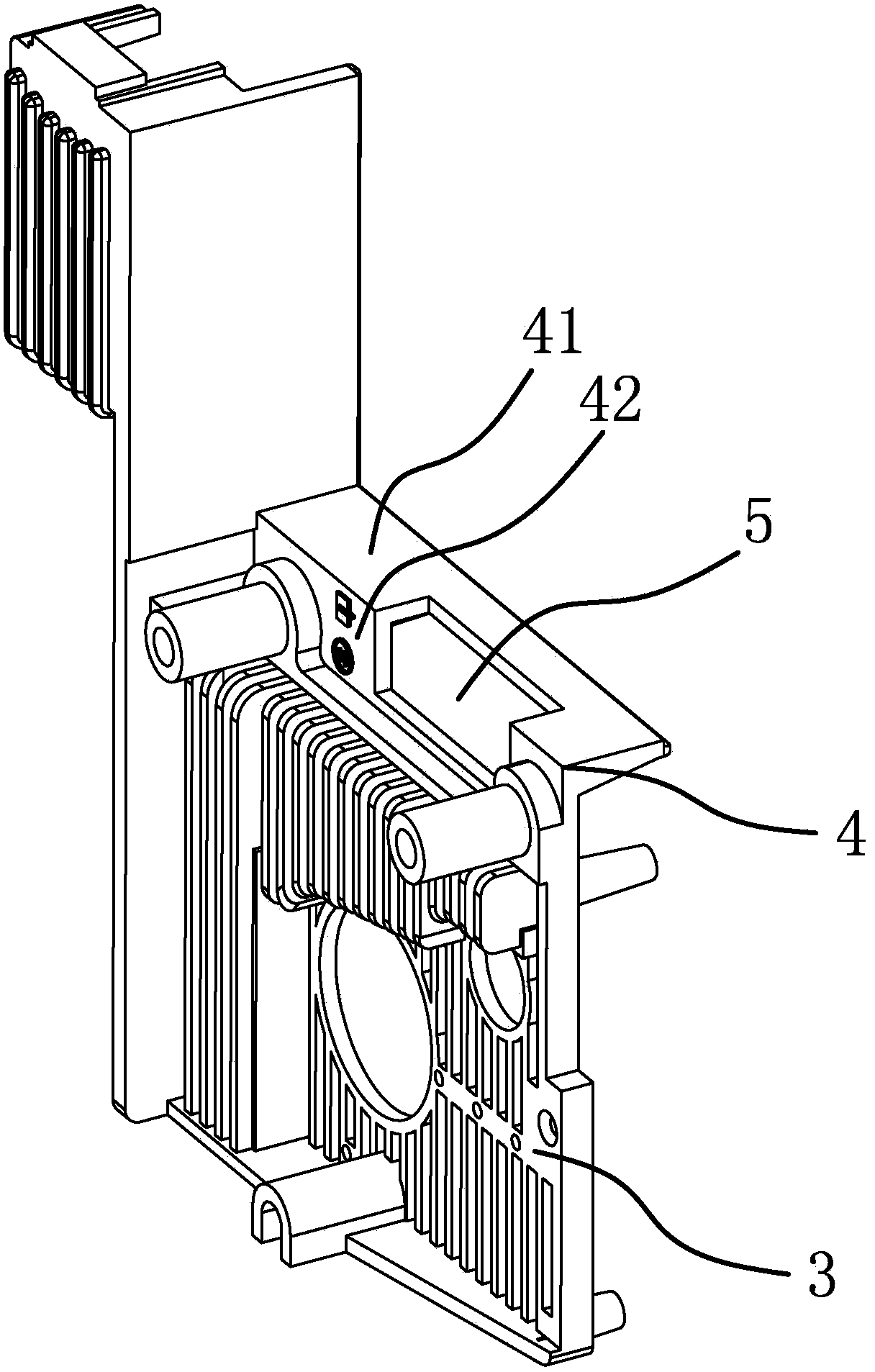

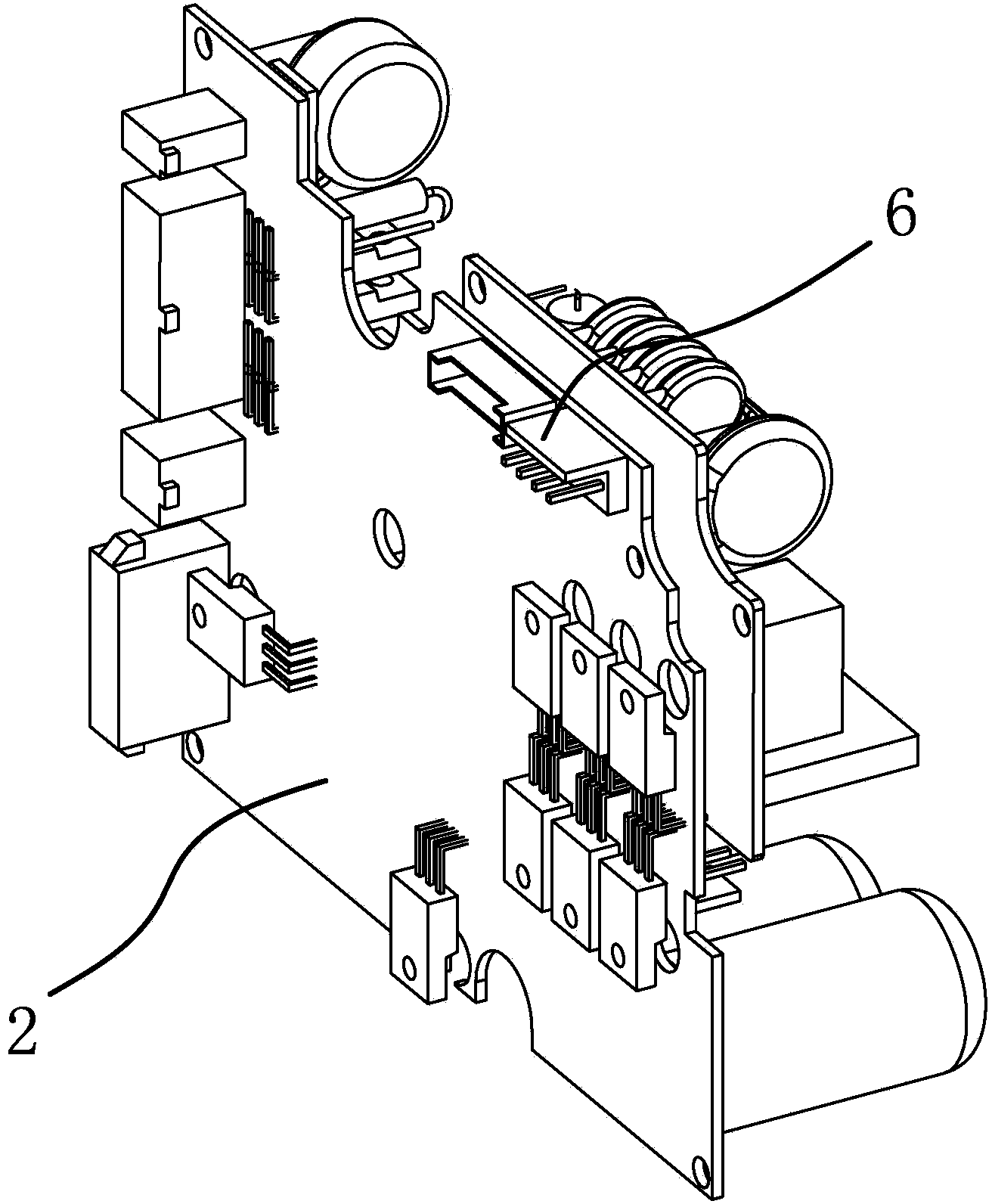

[0030] Such as figure 1 , figure 2 , image 3 , Figure 6 As shown, the lockstitch sewing machine control device includes a housing 1 , a circuit board 2 and a heat dissipation aluminum plate 3 . The housing 1 is in the shape of a box, with a cavity 11 inside, the motor is located on the upper part of the cavity 11 of the housing 1 (marked in the figure), the circuit board 2 and the heat dissipation aluminum plate 3 are located at the lower part of the cavity 11 of the housing 1, and The circuit board 2 is fixedly connected with the housing 1 through the heat dissipation aluminum plate 3 and bolts, the heat dissipation aluminum plate 3 seals the circuit board 2, and the heat dissipation aluminum plate 3 plays the role of heat dissipation and dustproof for the circuit board 2.

[0031] Such as figure 1 , figure 2 , image 3 As shown, the connection structure includes a connection plate 4 , a connection port 5 and a protective cover 7 .

[0032] The connection plate 4 i...

Embodiment 2

[0036] Such as Figure 7 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the connecting port 5 only runs through the connecting portion 42, that is, the connecting port 5 is located on the side of the connecting plate 4, the In this structure, the motor socket 6 can directly pass through the connection port 5, and the peripheral outer wall of the motor socket 6 is attached to the edge of the connection portion 42 at the edge of the connection port 5, that is, the motor socket 6 blocks the connection port 5, There is no need to provide the protective cover 7, and it also plays the role of dustproof and insulating, so that the whole connection structure is simple in structure and low in manufacturing cost. Of course, in actual production, a protective cover 7 matching the shape of the connection port 5 can also be provided in the connection port 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com