Bobbin grabbing device of spinning machine

A spinning frame and pipe grabbing technology, applied in textiles and papermaking, etc., can solve problems such as bobbin inclination, complex structure, and easy air leakage in gas pipelines, so as to enhance sealing, prevent air leakage, and prevent service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

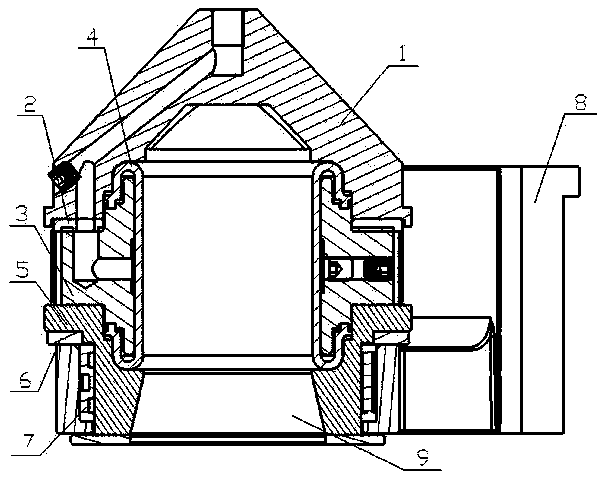

[0021] see figure 1 , a pipe grasping device of a spinning frame according to the present invention, which includes a pipe grasper base 8, on which the pipe grasper base 8 is sequentially provided with a pipe grasper upper cover 1, a pipe grasping timing pulley 3 and a pipe grasping The lower cover 5 of the pipe grabber, the upper cover 1 of the pipe grabber, the synchronous pulley 3 and the lower cover 5 of the pipe grabber form a gripping hole 9, and the upper cover 1 of the pipe grabber and the synchronous pulley 3 of the pipe grabber There is a pipe grab washer 2 between them, and the pipe grab upper cover 1 adopts an integral structure, and an air intake passage is arranged between the pipe grab upper cover 1, the pipe grab washer 2 and the pipe grab synchronous pulley 3, and the An air bag 4 is arranged on the pipe grabbing synchronous pulley 3, and an air-filled cavity is formed between the air bag 4 and the inner wall of the pipe grabbing synchronous pulley 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com