Multi-filament bundle equally-spaced filament-discharge compensation device of composite material filament paving head

A composite material and equidistant compensation technology, which is applied in the field of distance wire compensation device, can solve problems such as inconsistency in wire length, achieve the effects of improving product quality, reducing trimming procedures, and facilitating precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

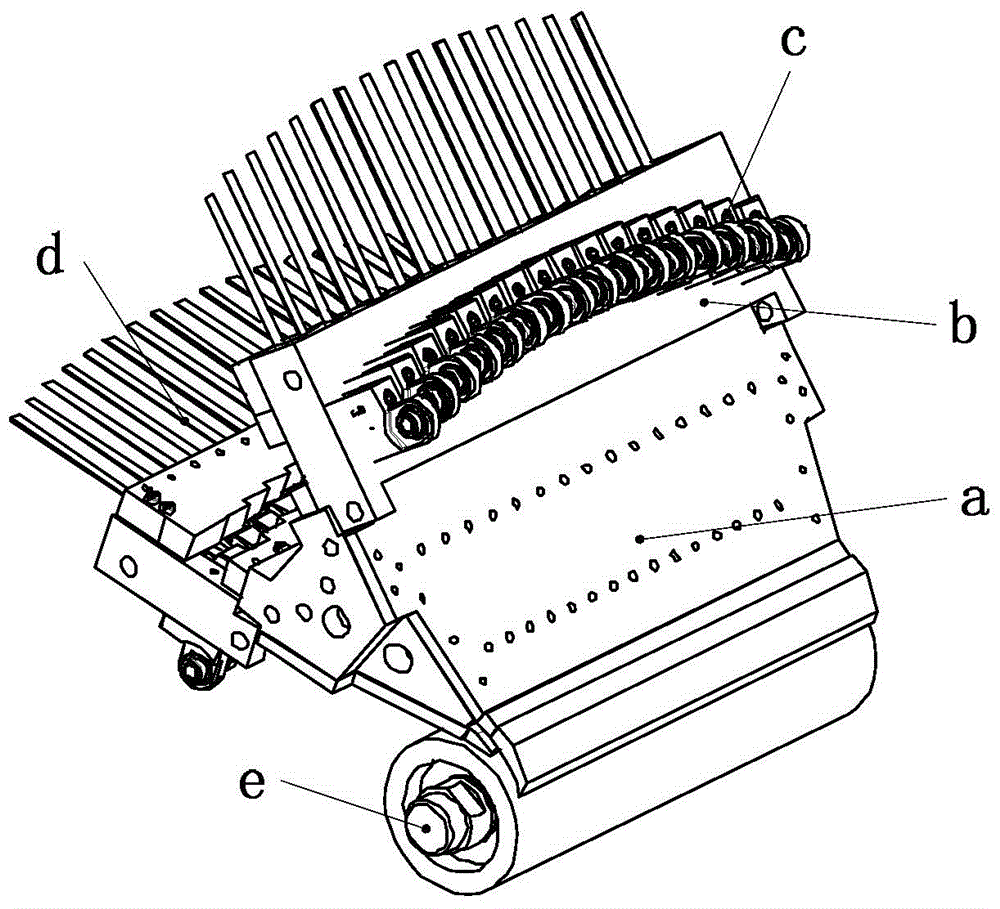

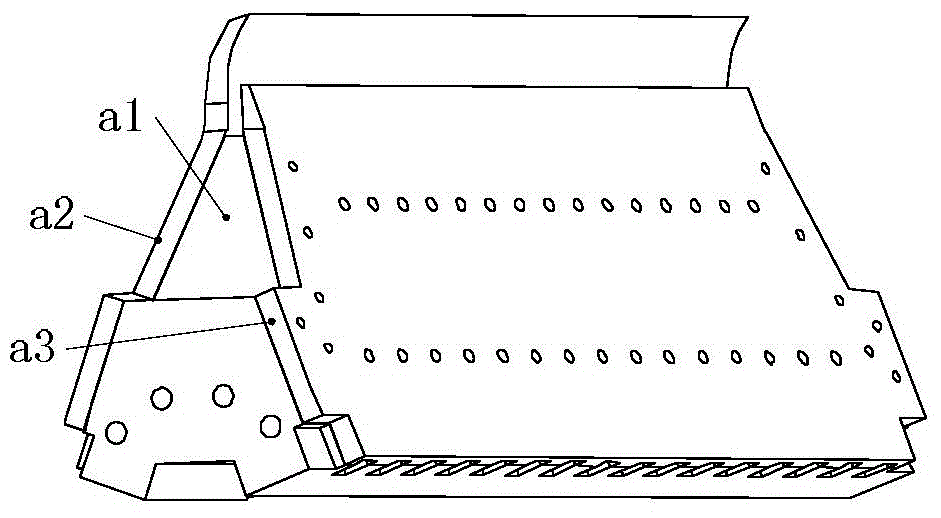

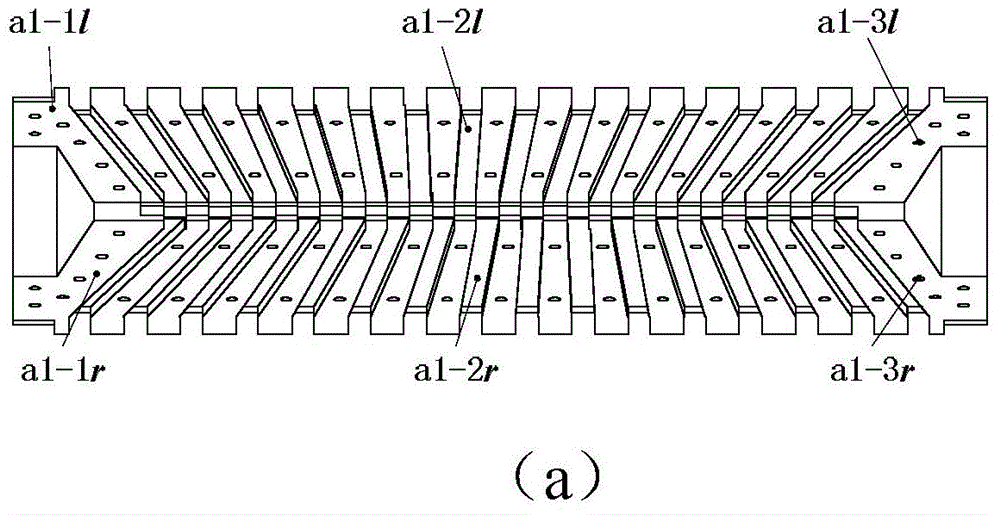

[0045] In order to solve the problem that the fiber tows pass through the guiding and combining device, because the guiding and combining device is a non-equidistant structure, the paths of the tows passing through the guiding and combining device are different, and there are always unequal lengths between the tows, and propose A compensation device that can realize equidistant filament output when laying multi-fiber tows, figure 1 It is a structural schematic diagram of the equidistant wire output compensation device of the present invention, such as figure 1 As shown, the compensation device includes: a guide beam combiner a, an equidistant compensation tool seat b, multiple sets of guide cutting and pressing cutter hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com