Pungent food making device

A technology for brewing spicy vegetables and equipment, which is applied in the field of equipment for brewing spicy vegetables, can solve problems such as unfavorable industrialization, inability to use spicy vegetables, and inability to store and maintain quality for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

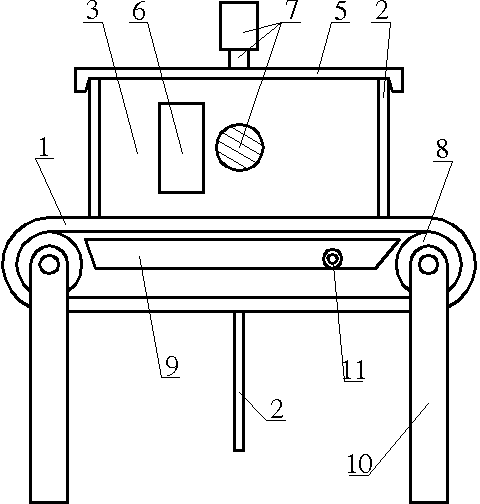

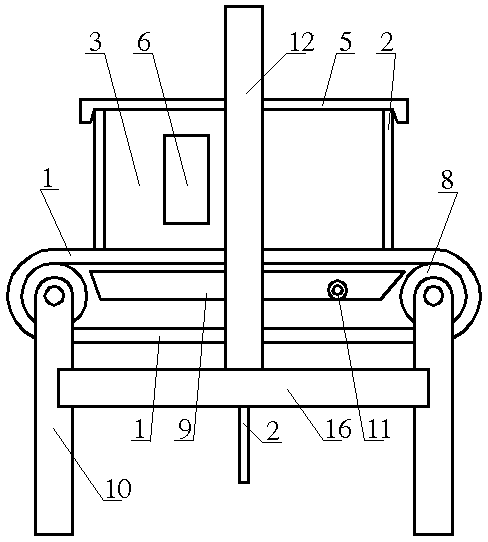

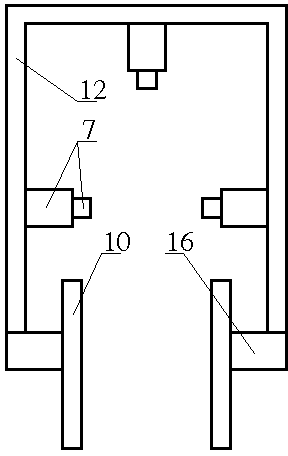

[0077] The equipment for preparing spicy dishes of the present invention mainly includes a lettuce squeezing machine and a kneading and wrapping machine;

[0078] The lettuce squeezing water machine mainly includes a rotating belt 1, a vertical plate 2, an extruding plate 3, a hydraulic telescopic cylinder 7, an eccentric vibrator 6, a buckle cover 5, a receiving tray 9, a rotating roller 8, a support frame 10, and a horizontal frame 16. Fixed frame 12, water leakage hole 13, water passing hole 14, vertical hole 15, hydraulic pump, electric motor, cycle control switch of computer version.

[0079] The vertical plate 2 is fixed on the rotating belt 1, and the rotating belt 1 is set on the rotating roller 8, and the two ends of the rotating roller 8 are fixed on the support frame 10 through bearings, and the shaft of the rotating roller 8 is directly or indirectly connected to the shaft of the motor. Connection; Extrusion plate 3 is installed on both sides above the rotary belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com