Constant value test system of reactor key process measurement parameters and test method

A technology of process measurement and test method, applied in reactors, nuclear reactor monitoring, nuclear engineering, etc., can solve problems such as unsteady hidden dangers, low work efficiency, poor control of adjustment accuracy, etc., to reduce the number of disconnected terminals and set them accurately And stable, reduce the effect of the number of signal sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

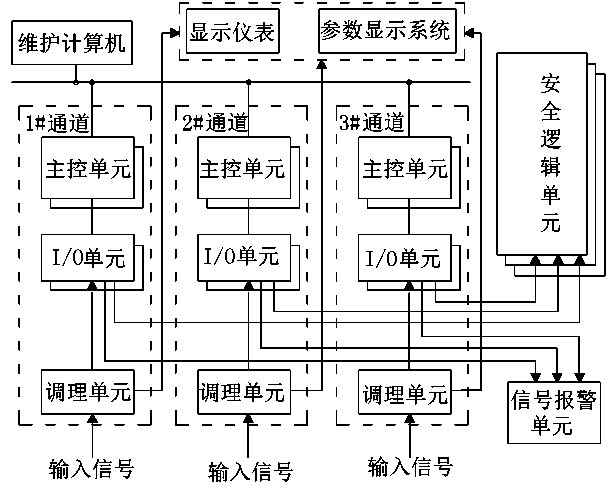

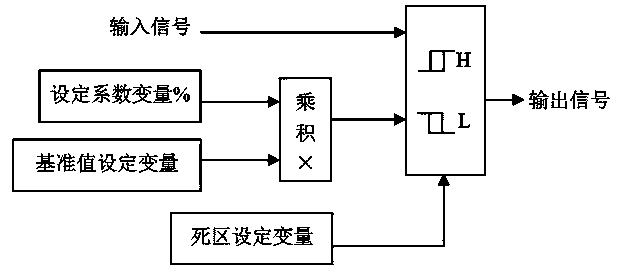

[0043] Such as Figures 1 to 2 As shown in the present invention, a reactor key process measurement parameter fixed value test system includes three mutually redundant channels, each of which includes a conditioning unit: used to receive signal input, isolate the signal and deliver it to I / O unit, display through the display instrument and parameter display system; I / O unit: transmit the input signal of the signal unit to the main control unit, and send the output signal of the main control unit to the safety logic unit and / or signal alarm unit ;Main control unit: calculates the input signal, compares the input signal with the threshold value; safety logic unit: used to receive the signal sent by the main control unit in each channel for logical operation; signal alarm unit: used to receive the main control unit alarm signal and alarm; maintenance computer: used to modify and test the alarm thresholds of all parameters of the main control unit.

[0044] Fixed value test can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com