High core wall rock-fill dam foundation seepage prevention structure on deep overburden layer

A technology of deep covering layer and dam foundation anti-seepage, applied in infrastructure engineering, dams, barrages, etc., can solve the problems of long construction period, high investment, not meeting the anti-seepage requirements of high dams, etc., to increase the water head ratio and reduce seepage. leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

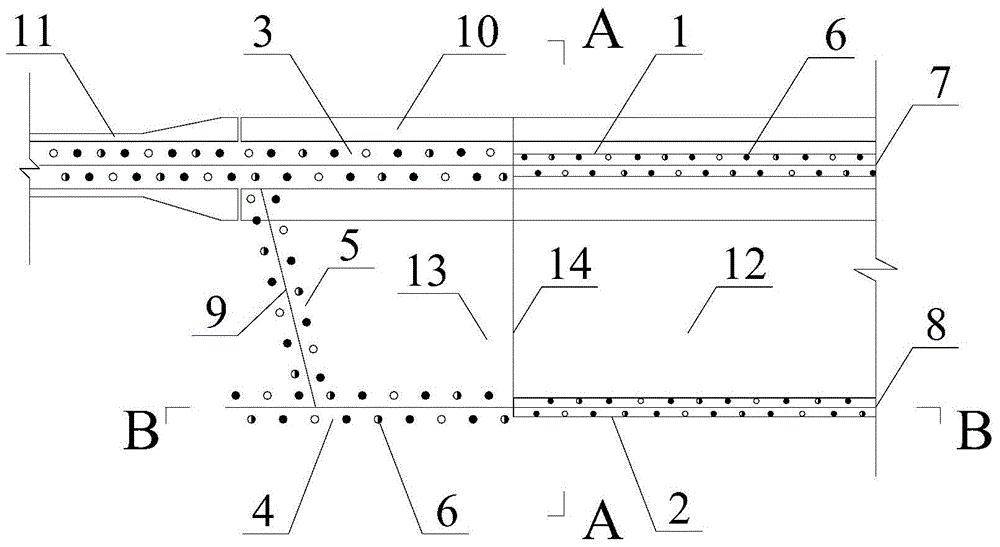

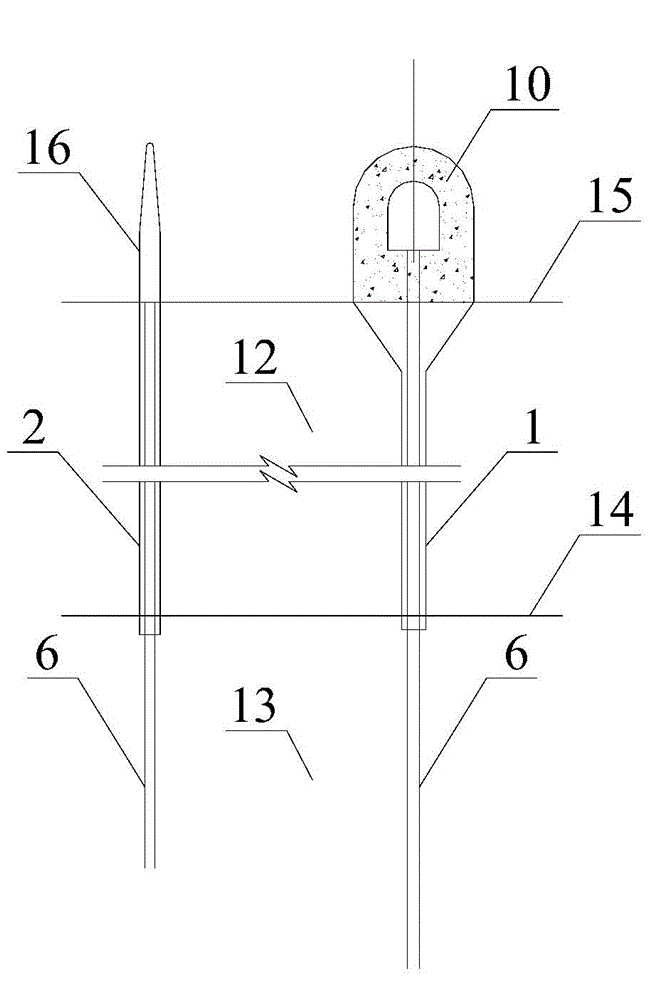

[0023] After the original ground line of the river bed is excavated to the dam foundation surface 15, the main cut-off wall 1 and the auxiliary cut-off wall 2 are drilled and grooved using a percussion drill or a double-wheel milling machine. The main cut-off wall 1 is located at the main On the center line of the anti-seepage plane, the auxiliary anti-seepage wall 2 is located on the upstream side of the main anti-seepage wall 1, and the clear distance between the main anti-seepage wall 1 and the main anti-seepage wall 1 is 12-14m. Penetrate the overburden layer 12 of the riverbed and insert 1 to 1.5m into the bedrock. The inclination of the slot is tracked and detected by an ultrasonic logging tool to ensure the verticality of the slot. After the slot hole construction is completed and the holes are cleaned and grouted, the concrete pouring of the main cut-off wall 1 and the auxiliary cut-off wall 2 is carried out by using the straight-up conduit method. The main cut-off wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com