Pressurized industrial exhaust gas energy utilization method

A technology for industrial exhaust gas and energy, applied in pressure pumps, non-displacement pumps, machines/engines, etc., can solve problems such as power consumption, improve efficiency, operate flexibly, and avoid mechanical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

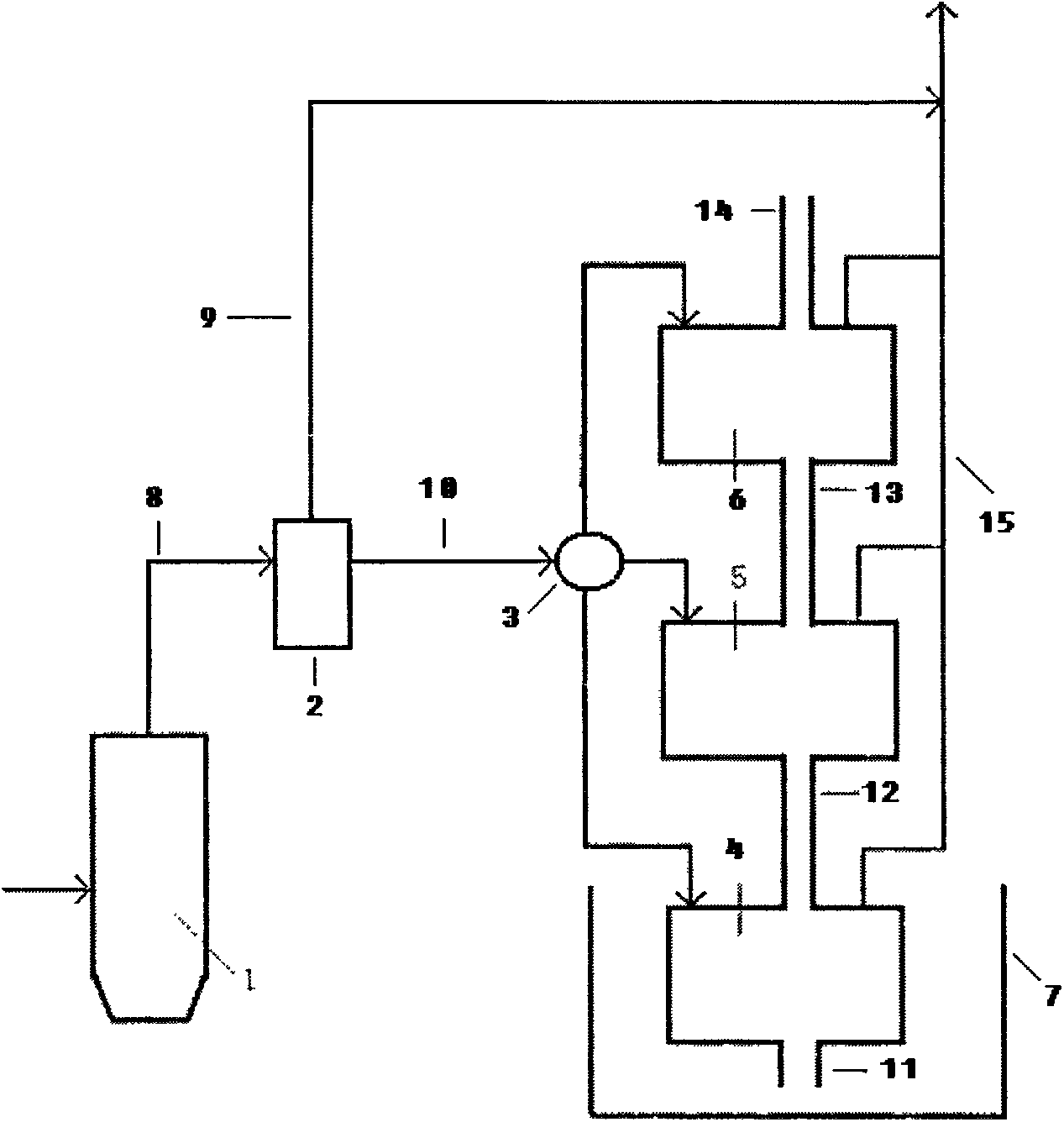

[0018] attached figure 1 It is a specific embodiment in which a multi-stage air pressurized water machine is driven by pressurized industrial tail gas. As shown in the figure, the pressurized industrial tail gas enters the tail gas purification device 1 through the pipeline. After removing solid or liquid substances or doing corresponding treatment, it enters the pressure stabilizing device 2 through the gas transmission pipeline 8. After the pressure is adjusted by the stabilizing device 2, it is discharged. The exhaust gas under pressure enters into and drives the primary air pressure water press 4, the secondary air pressure water press 5, and the third air pressure water press 6 respectively through the air intake pipe 10, and the water in the pool 7 enters the primary air pressure water press through the water inlet pipe 11. After the pressurized water machine 4, it continuously enters the secondary air pressurized water machine 5 through the upper water pipe 12 under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com