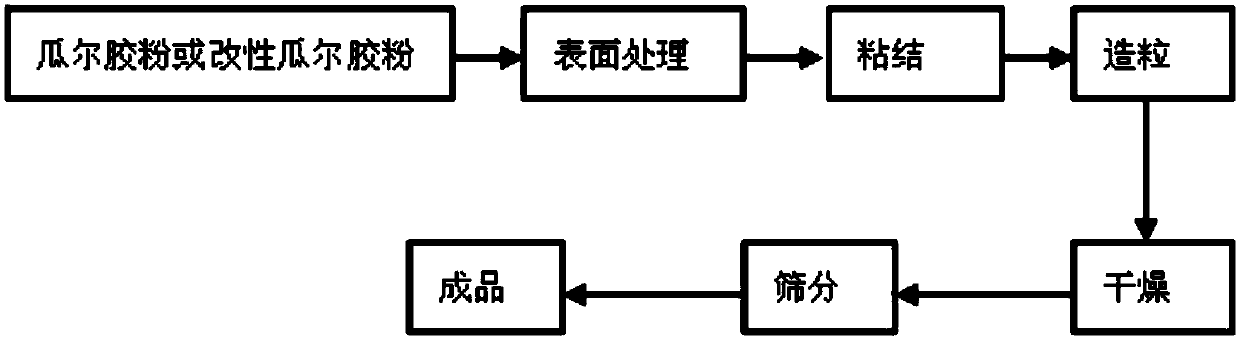

A kind of preparation method of easily dispersible dust-free guar gum particles

A guar gum, dust-free technology, applied in the field of preparation of modified guar gum, can solve the problems of injury to workers, serious dust, environmental pollution, etc., and achieve the effect of reducing dust damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Get 100 mass parts of guar gum powder as raw material, add 1 mass part of surfactant JKS and 10 mass parts of ethanol mixed solution to carry out surface treatment of guar gum, react for 2 hours, then add 30 mass parts of binder water, pass The rotation of the disc makes the binder water and the guar gum powder come into close contact with each other to generate cohesive force and form porous and loose aggregates, then dry them in a boiling drying oven at 75°C, and finally sieve to obtain particles with a size of 1 to 5 mm of granular guar gum products.

Embodiment 2

[0017] Get 100 mass parts of modified guar gum powder raw materials, add 1.5 mass parts of fatty acid salt and 10 mass parts of ethanol mixed solution to carry out surface treatment to guar gum, react for 2 hours, then add 30 mass parts of binder water, in Under the action of different wind forces, the rubber powder floats up from the middle of the core tube in the tube, contacts with the binder water sprayed from the spray gun installed in the center of the bottom, and then bonds with the powder falling from the top, and then settles down from the outside of the core tube to form The particles are circulated up and down to make the particles evenly grow into porous and loose particles, followed by vacuum drying at 70°C and a vacuum degree of 0.092MPa for 2 hours, and finally sieved to obtain granular guar gum products with a particle size of 1-5 mm.

Embodiment 3

[0019] Get 100 mass parts of guar gum powder raw material, add the mixed solution of 1 mass part gelatin and 30 mass parts water to carry out surface treatment to guar gum, react for 2 hours, then add 20 mass parts of binder water, in different wind Under the action, the rubber powder floats up from the middle of the core barrel in the barrel and contacts with the binder water sprayed out by the spray gun installed in the center of the bottom, and then bonds with the powder falling from the top and then settles down from the outside of the core barrel to form the upper and lower layers of the particles. Circulate the flow to make the particles evenly grow into porous and loose particles, then dry them in an airflow drying oven at 70°C, and finally sieve to obtain granular guar gum products with a particle size of 1 to 5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com