Slide rail socket

A technology of slide rails and sockets, which is applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems of low flexibility of use and inability to realize effectively, so as to improve the safety of use, realize the cost of electricity, and avoid poor power contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

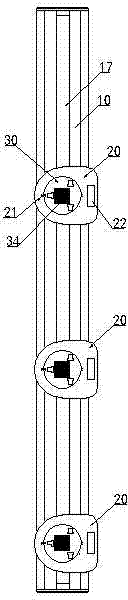

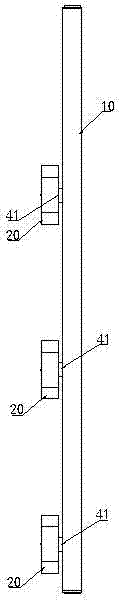

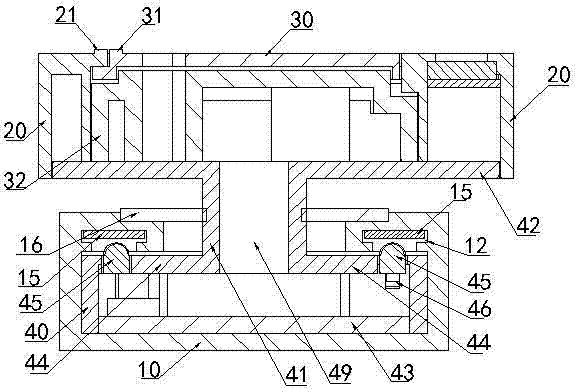

[0033] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 , Figure 9 In the shown embodiment, a slide rail socket includes a slide rail base 10, a chute is opened in the slide rail base 10, and the two side walls 18 of the chute have a hook body 11 at the upper end of the slide rail base that extends upward and inwardly. , two conductive strips 14 are respectively installed at the back positions of the hook bodies 11 at the upper ends of the two slide rail bases along the length direction of the slide rail base 10, the conductive strips 14 are sheet-like long copper strips, and the two conductive strips 14 They are respectively electrically connected to the AC power supply, and the distance between the upper end hook bodies 11 of the two slide rail bases forms the upper port sliding track 17 in the length direction of the slide rail; Rotatable socket base, the specific number can be set separately according to the actual needs to form slide rail socket...

Embodiment 2

[0035] figure 1 , Image 6 , Figure 7 In the shown embodiment, the power socket includes a socket housing 20 and a socket body 36. A socket cover 30 is installed on the upper surface of the socket body 36. The socket housing 20 can be installed on the socket body 36 and the socket cover around the angle of rotation of the socket cover 30. At the outer periphery of the plate 30, the socket housing 20 and the socket cover 30 are respectively provided with reference lines aligned with each other, wherein the socket housing 20 is provided with a socket housing reference line 21, and the socket cover 30 is provided with a socket cover reference line 31 (See Image 6 , Figure 7 ); when rotated to align with the reference line, the cover plate jack 33 on the socket cover 30 is aligned with the socket jack on the socket body 36 and the plug can be inserted to connect electricity (see Image 6 ), after rotating and staggering the reference line, the cover hole on the socket cove...

Embodiment 3

[0037] A liquid crystal display window 22 is installed on the socket shell 20 , and a useful electricity metering circuit module is installed inside the socket shell 20 , and the electricity metering circuit module is electrically connected to the liquid crystal display window 22 . Others are identical with embodiment 1 or embodiment 2. It is more clear about the power consumption of each power socket, and it is easier to calculate the electricity cost of the power used by a single power socket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com