Hexapod robot manipulation system and manipulation method

A technology of a hexapod robot and a manipulation system, which is applied to the manipulation system and manipulation field of a hexapod robot, can solve the problems of poor real-time communication, complicated manipulation, and poor man-machine coordination and integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

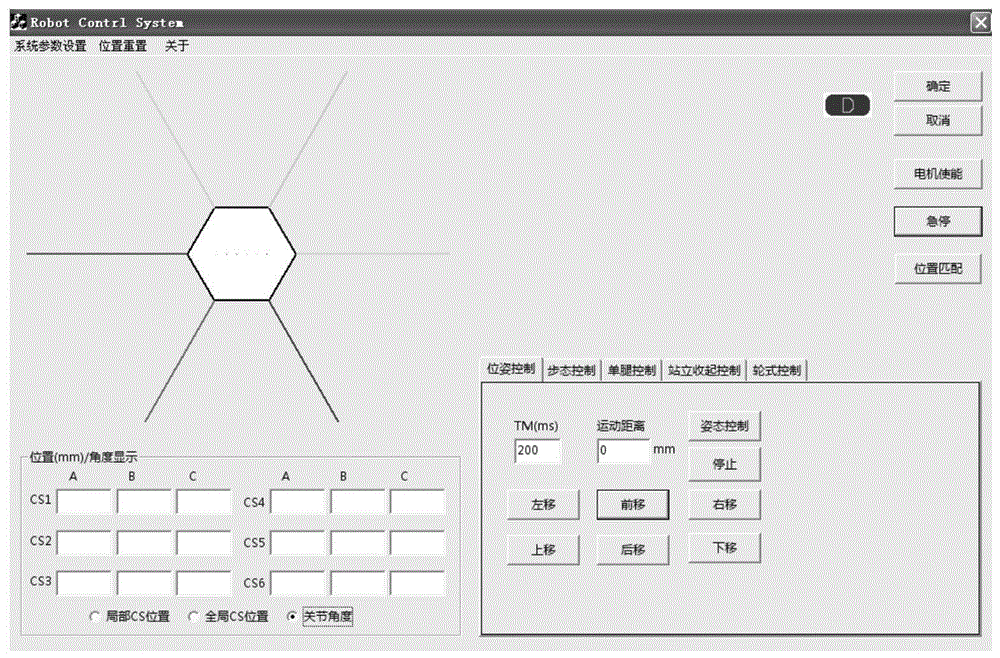

[0124] Specific implementation mode one: the operation interface of the hexapod robot manipulation system is as follows: figure 1 Shown; the hexapod robot control system, including the following modules: motor enable control module, stop module, parameter setting module, position reset module, pose control module, gait control module, single-leg control module, standing and retracting control module, wheel control module and position display module;

[0125] The motor enabling control module is used for the power-on control of the robot's action motor;

[0126] The stop module is used for the stop control of the robot execution action;

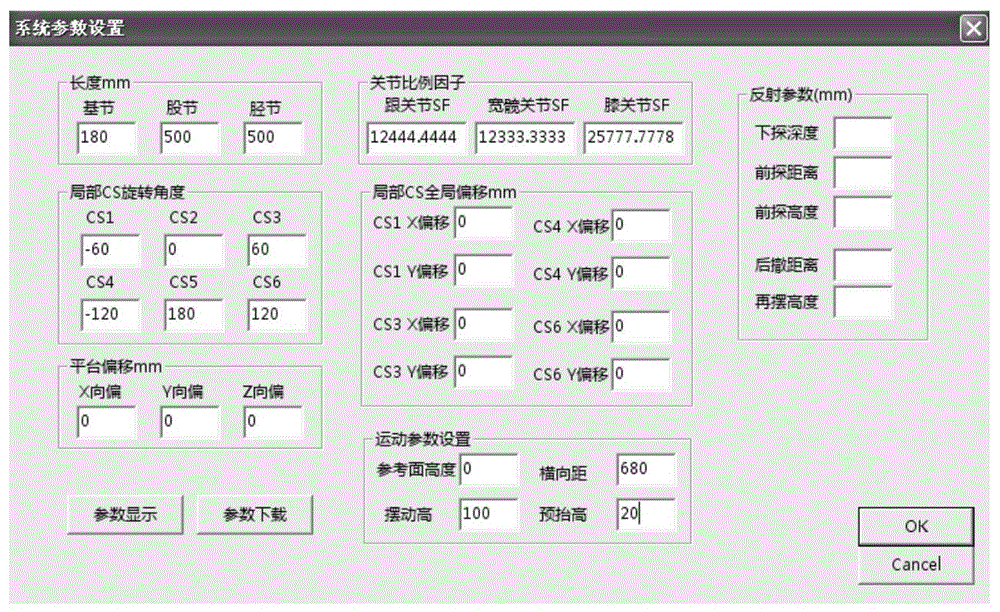

[0127] The display interface of the parameter setting module is as follows: figure 2 As shown; the parameter setting module is to input the parameters of the robot, including:

[0128] LegLength_1 / 2 / 3 parameter input sub-module, that is, base segment length, thigh length and calf length parameter input sub-module; used for base segment len...

specific Embodiment approach 2

[0196] Embodiment 2: The hexapod robot control system is developed on the basis of Visual C++6.0, and communicates with the control system by embedding the dynamic link library Pcomm32 provided by UMAC.

[0197] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0198] Specific embodiment three: utilize the method for manipulating a robot with a hexapod robot manipulating system, comprising the following steps:

[0199] Step 1: Run the motor enable control module to make the motor in working state;

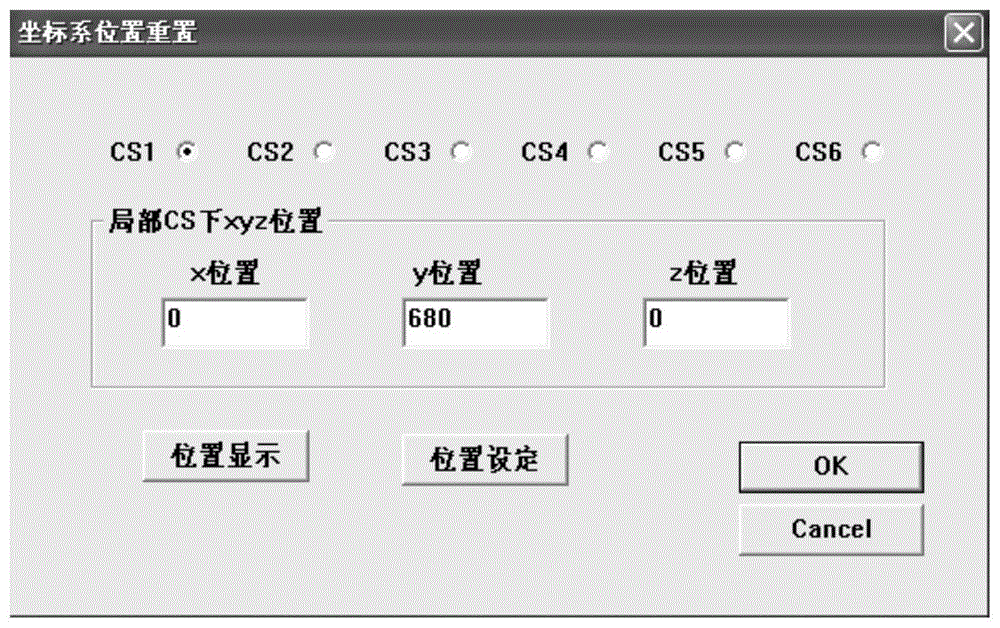

[0200] Step 2: Run the position reset module to set the initial position of the robot's legs in the local coordinate system, so that the robot can return to zero;

[0201] Set the initial position of the robot's single leg of the six-legged Choose_CS_1 / 2 / 3 / 4 / 5 / 6 in the local coordinate system, including: the setting of the x position Ed_xPos, the setting of the y position Ed_yPos in the local coordinate system, and the setting of the z position Ed_zPos set up;

[0202] Step 3: According to the actual situation of the robot, run the system parameter setting module and set the system parameters; including:

[0203] Enter LegLength_1 / 2 / 3, that is, the length of the base segment, the length of the thigh and the length of the calf;

[0204]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com