Method for reducing three-coordinate measuring compensating error of blade surface

A three-coordinate measurement and error compensation technology, applied in the field of measurement, can solve the problems of large cosine error and affect the accuracy of measurement evaluation, etc., and achieve the effect of solving the problem of cosine error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

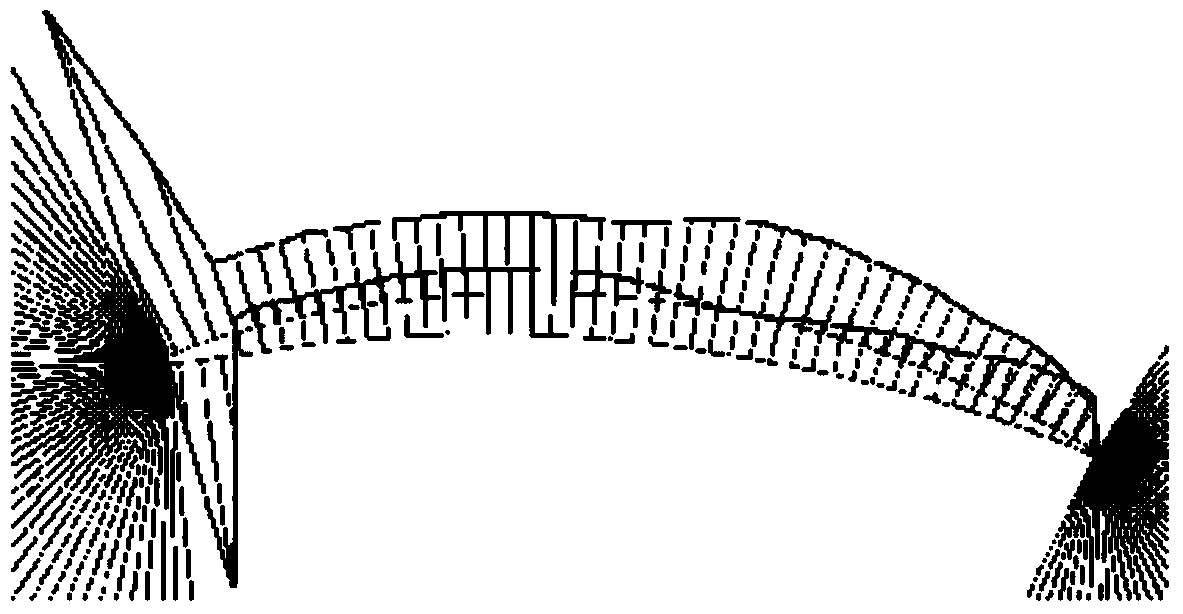

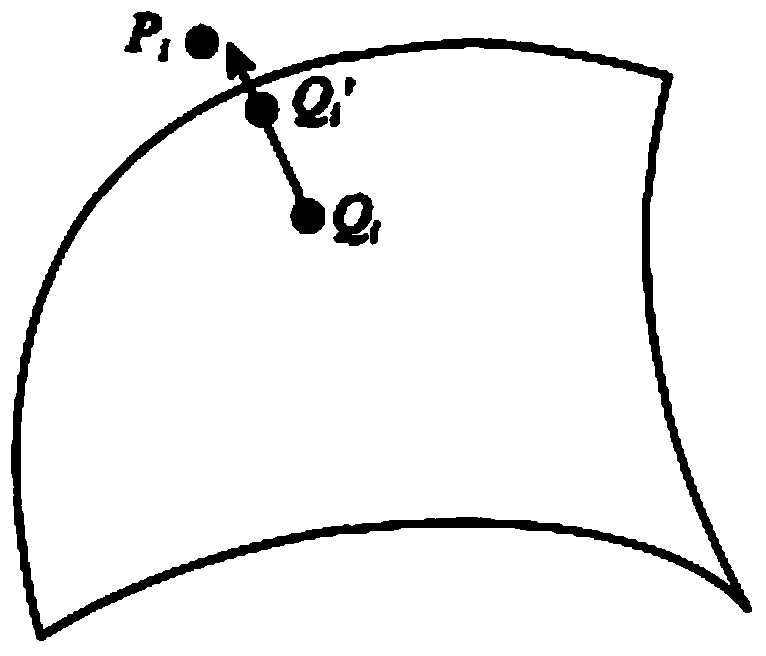

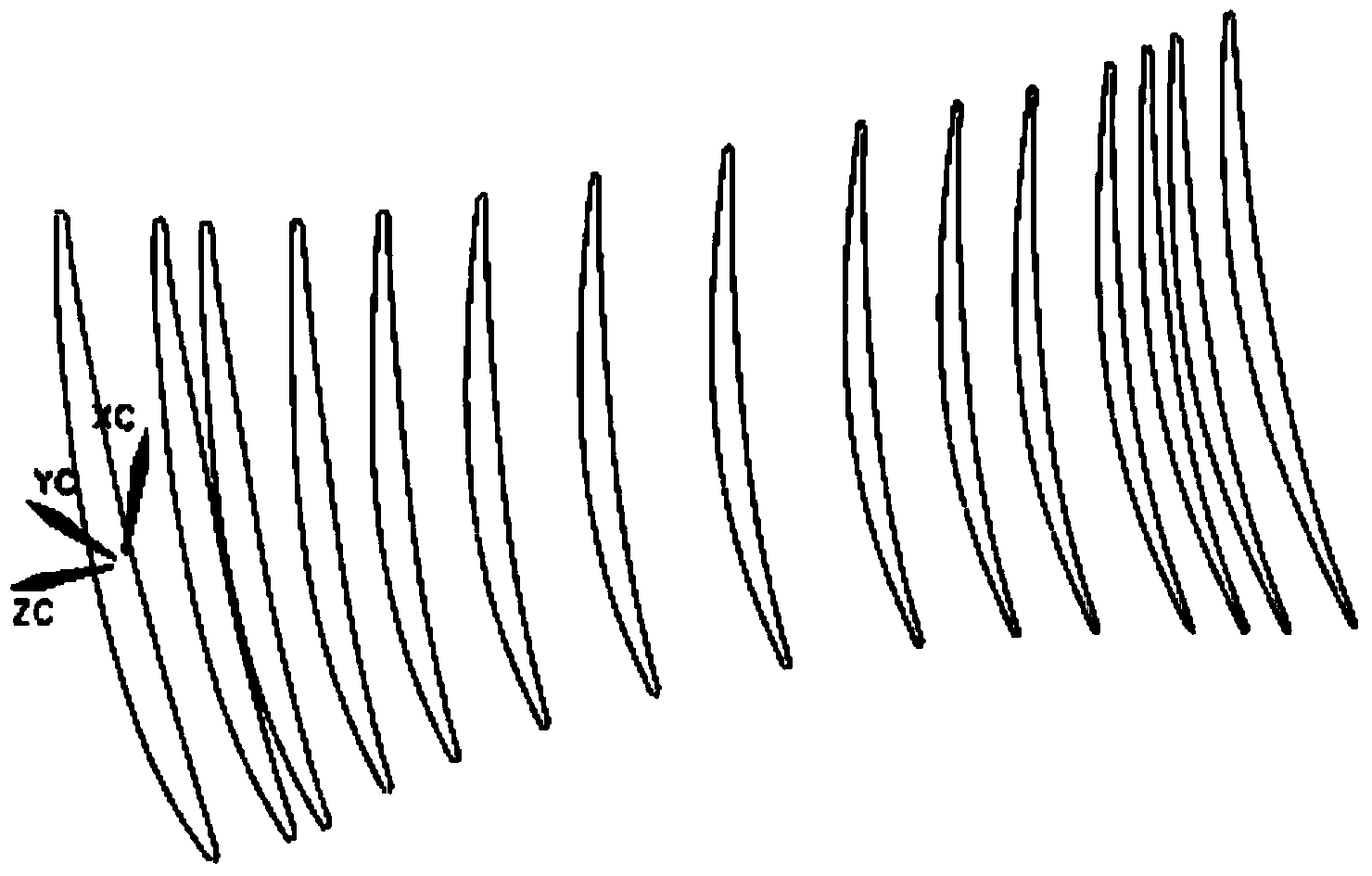

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 5 As shown, according to the problem of cosine error in the two-dimensional cross-sectional scanning of a certain end-curved blade using a three-dimensional coordinate measuring machine, resulting in a large deviation of the measured data, the method of the present invention is used to measure the end-curved position. to reduce measurement errors.

[0026] The specific implementation method is:

[0027] Make a new measurement surface

[0028] The vectors of each point of the blade body section are as follows: figure 1 As shown, the coordinates are shown in Table 1;

[0029] Table 1

[0030]

[0031] (1) According to the X, Y, Z coordinates of the design drawing, make a section curve forming multiple sections;

[0032] #Z,-124.5

[0033] P1, X-46.4982, Y-6.9525

[0034] P2, X-43.9148, Y-6.6336

[0035] P3, X-41.4438, Y-6.1816

[0036] P4, X-39....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com