Quick movement tooling for gantry crane

A gantry crane, fast technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of large working area, long cycle, high cost, etc., achieve high safety factor, easy operation and control, and reduce the effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with drawings and embodiments.

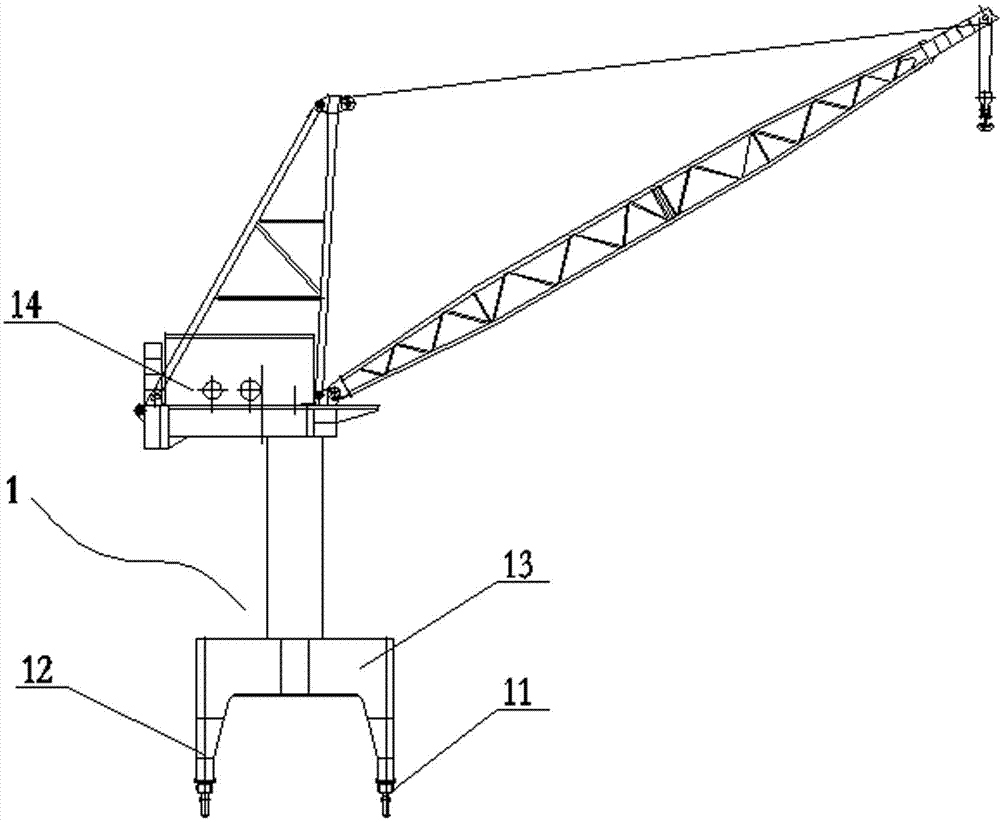

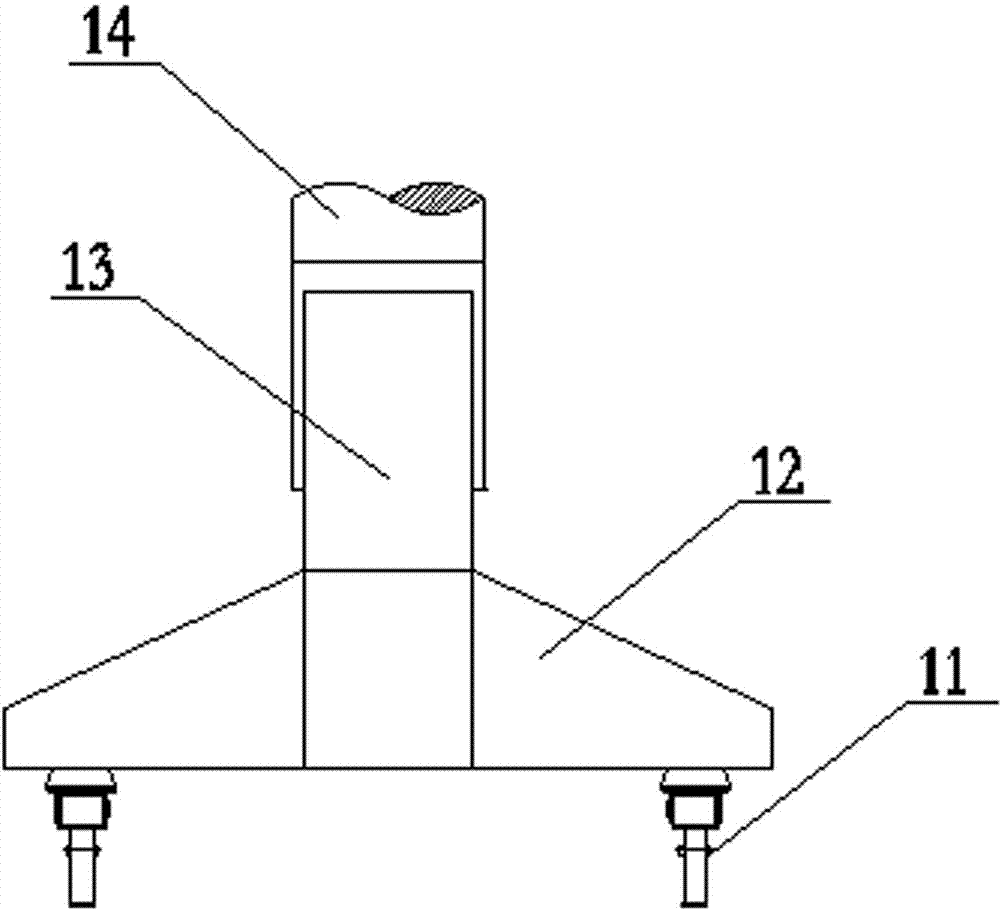

[0016] figure 1 , 2 The portal machine 1 shown is composed of 14 hoisting devices that are rotatably mounted on a portal frame. The portal frame includes four legs 11, beams 12 at both ends and beams 13. The beams at both ends 12 are arranged in parallel. The two ends are respectively supported by supporting legs 11, and the beam 13 is vertically supported on two end beams 12 arranged in parallel.

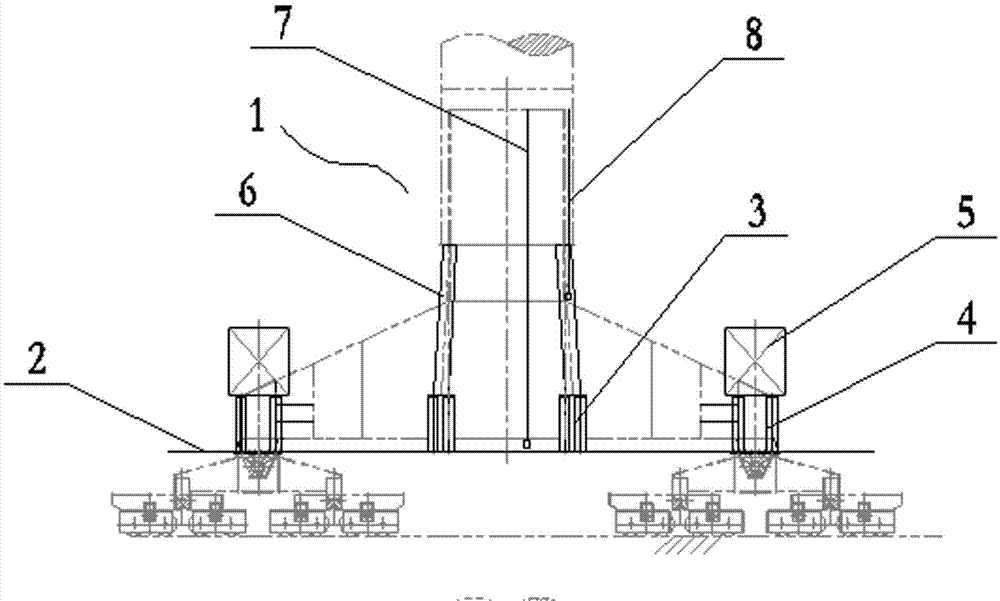

[0017] image 3 , 4 As shown, a quick shift tooling for a gantry crane includes a lifting transport platform car 2, two middle beams 3, two end beams 4, two shift supports 6 and a counterweight 5, and the two middle beams 3 are arranged on two sides in parallel and at intervals. Between the end crossbeams 4 and the four crossbeams are all supported on the lifting transport flatbed truck 2, the two displacement supports 6 are respectively arranged on the two middle beams or on the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com