Packing box boxing and sealing device

A packaging and sealing technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of low production efficiency, labor consumption, and increase packaging production costs, so as to reduce operating costs, reduce manual intervention, The effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

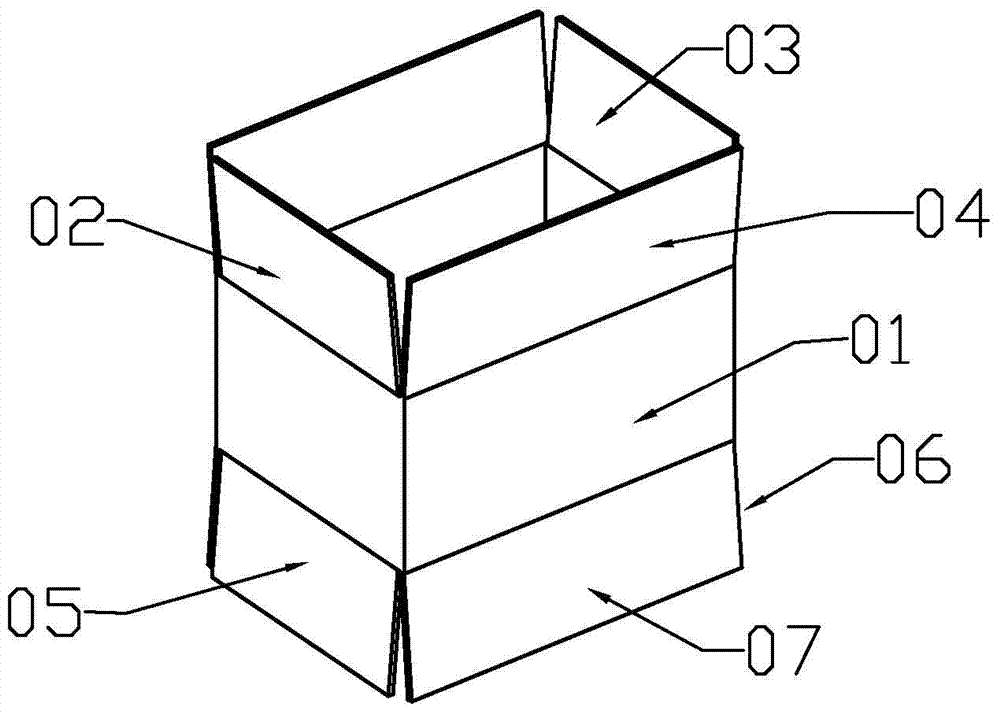

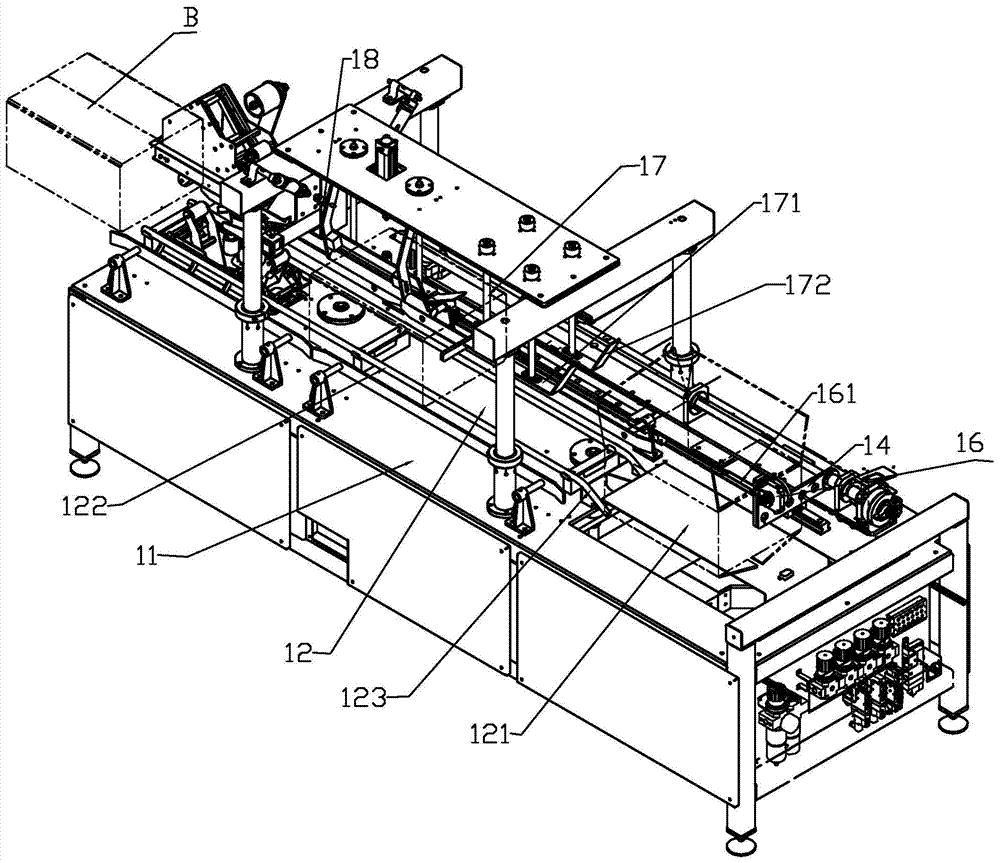

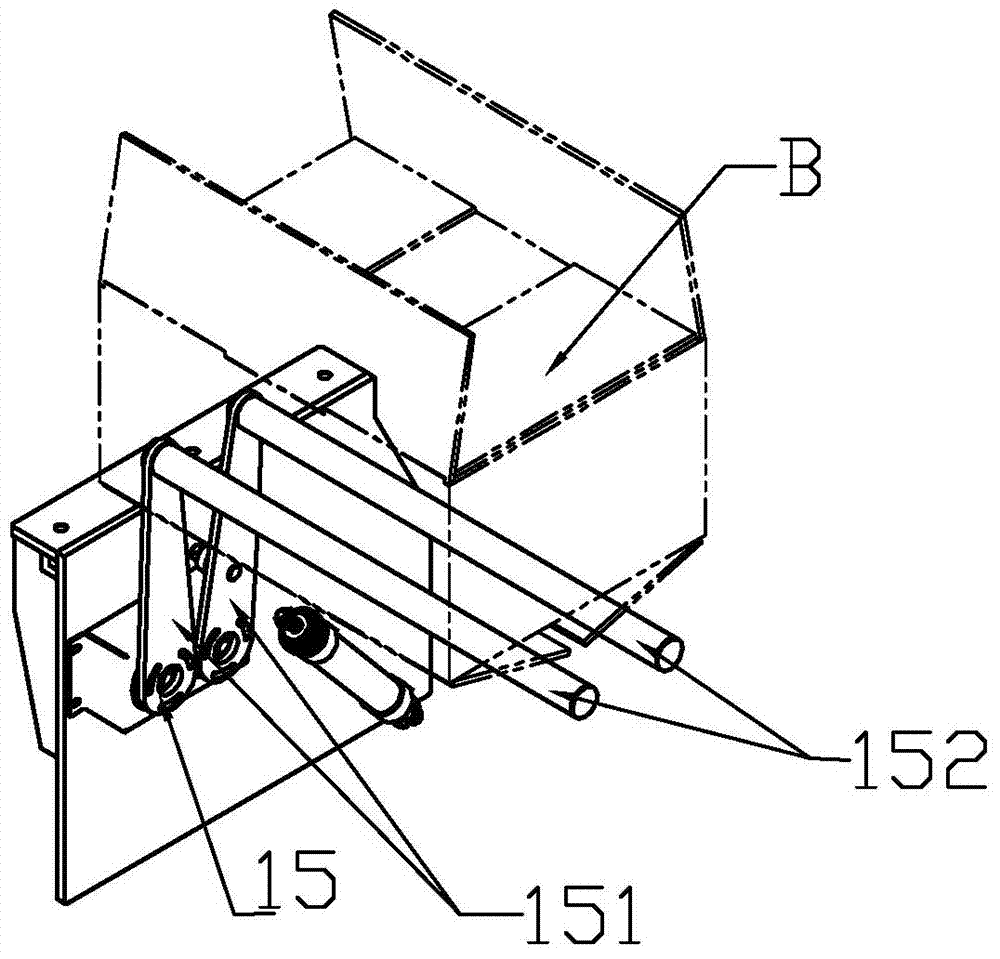

[0017] Such as figure 2 As shown, the packing and sealing device of the packaging equipment includes a horizontal conveying channel 12 located on the frame 11 through which the packing box B can pass, and also includes a manipulator 13 located above the conveying channel capable of holding and releasing the packing box; There is a support plate 121 at the bottom of the rear section of the conveying channel, and the bottom of the front section of the conveying channel is a section of conveying track 122, and the rear end of the conveying track 122 is inclined downward to form a vertical neutral guide section 123 between the supporting plate; There is a driving arm 14 that can move longitudinally under the drive of the power unit and push the packaging box B to move forward. The driving arm 14 is driven by a stepping motor through a screw mechanism to move longitudinally; The front and rear tilting swings and vertical lifting actions can turn the front piece of the lower cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com