Abutting welding method for box columns of large-scale factory building

A welding method and box-shaped column technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems affecting the quality of box-shaped column welds and the construction period of structural installation, large butt joint section size, uneven heating of welds, etc. , to achieve the effect of shortening the installation time of butt welding, small welding stress and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

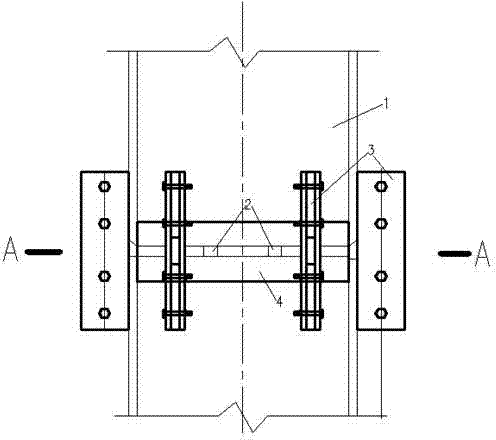

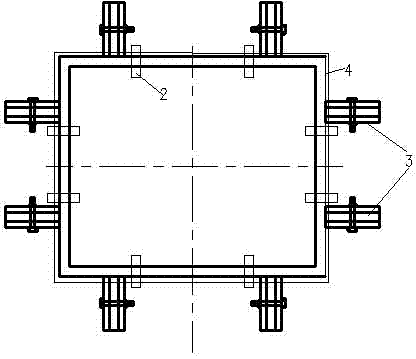

[0014] Referring to the accompanying drawings, a butt welding method for box-shaped columns of a large factory building, its specific technical scheme is:

[0015] A. Preparation before welding: install the positioning plate of the box-shaped column, install the box-shaped column: minimize the amount of misalignment when aligning butt joints, and the amount of misalignment should be controlled below 2.0mm. -2.0mm, the gap is required to be 1.0-3.0mm and the gap plate is installed, and the verticality and elevation are adjusted; after adjustment, the positioning plate of the box column is fastened to control the shrinkage of the weld seam, reduce the welding deformation, and take windproof measures;

[0016] B. Preheating before welding: Before welding, clean the rust, oil stains and polish within 10-20mm of the welded joint and the groove, and then preheat the base metal with an oxyacetylene flame. The preheating temperature is 100- 150°C, the preheating width is within 100mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com