Elastic waistline shaping machine for waist-surrounding paper diaper

A technology of ring-waist paper and forming machine, which is applied in medical science, bandages, absorbent pads, etc., and can solve problems such as uncomfortable wearing of babies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

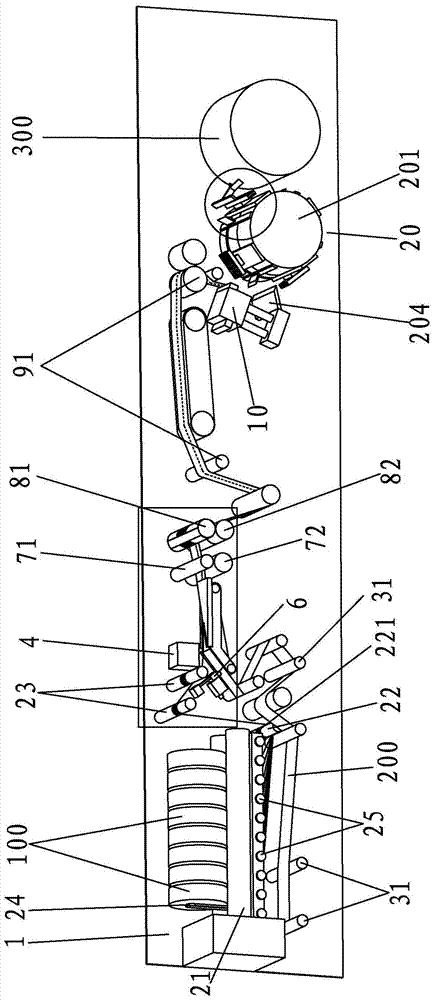

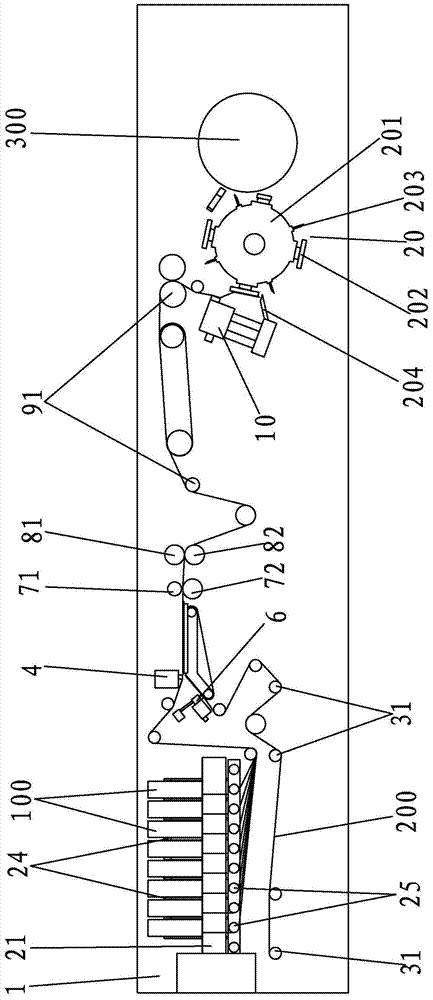

[0023] The elastic waist forming machine of a kind of ring-waist diaper of the present invention, as Figure 1-4 As shown, it includes a frame 1, and is arranged on the front side of the frame 1 for a number of elastic rolls 100 to be placed side by side at intervals, and the elastic on each elastic roll 100 is pulled out and transported side by side at a certain interval. Ribbon output device, non-woven fabric output device that transports roll-shaped non-woven fabric rolls, rubber band gluing mechanism that glues the surface of each elastic band, non-woven fabric that glues the surface of the output non-woven fabric The gluing mechanism, the half-folding mechanism for folding the output non-woven fabric in half, the cutting knife rest for partial breakpoint cutting of the elastic, the turning knife rest on the right side of the cutting k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com