Rotating machinery fault simulation platform

A fault simulation and rotating machinery technology, applied in teaching models, educational tools, instruments, etc., can solve the problem of single function of the rotating machinery fault detection experiment platform, achieve visualization, enhance functions, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

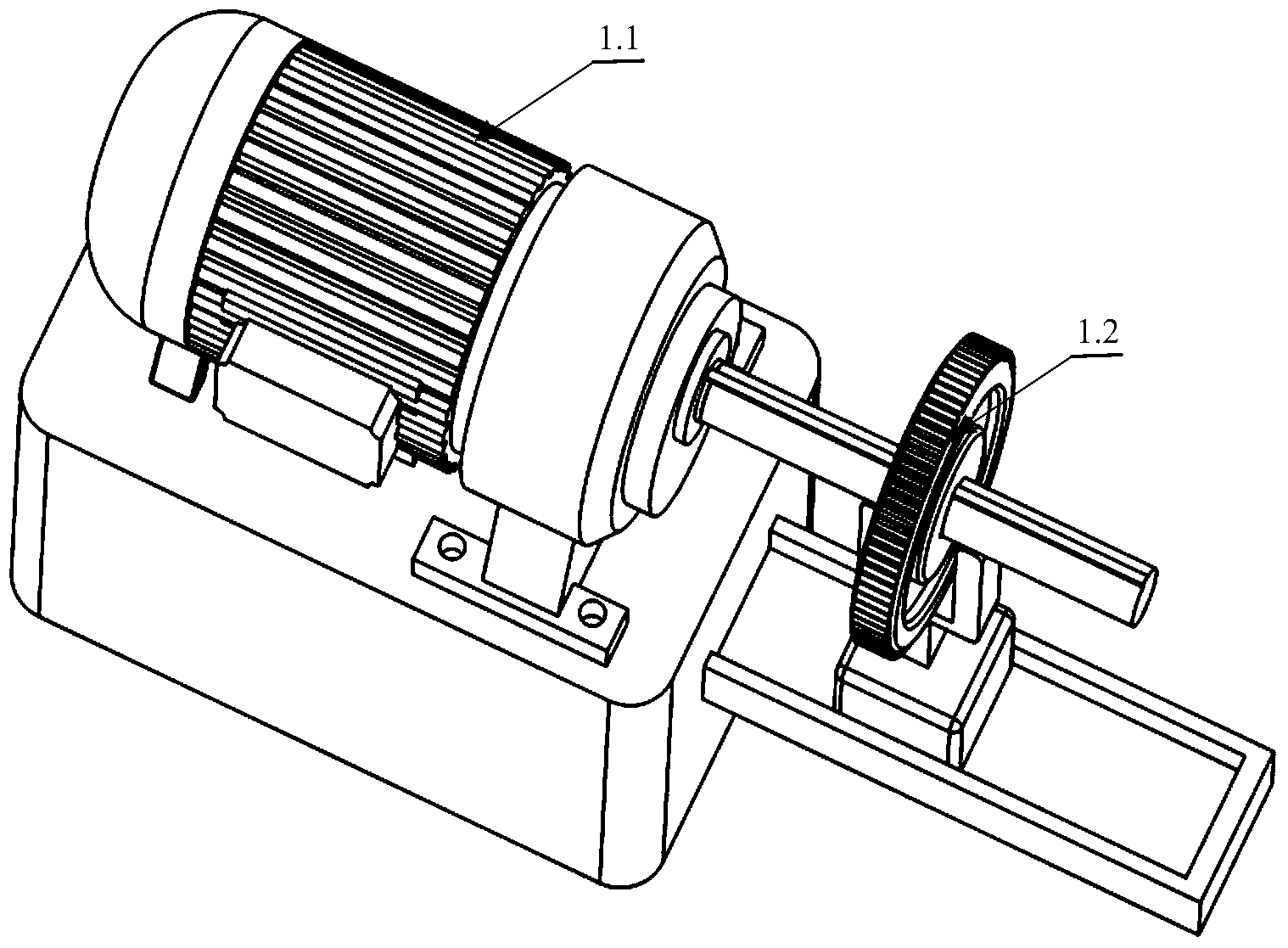

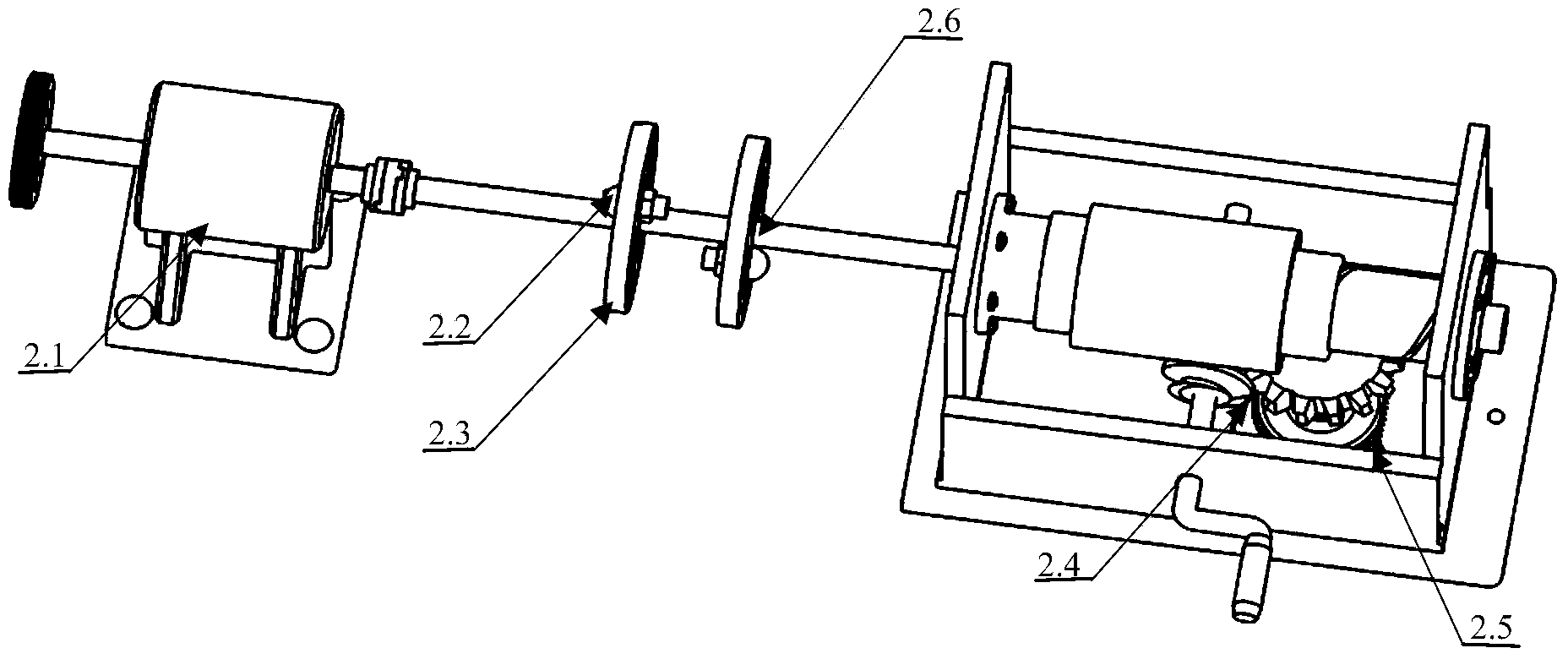

[0031] The rotating machinery failure simulation platform provided by the present invention has a structure such as Figure 1 to Figure 6 As shown, it includes a sliding gear mechanism 1.2, a combined mechanism of a worm gear 2.4 and an incomplete internal gear 2.5, a screw nut mechanism 2.6, a sheave mechanism 3.5 and a triple sliding gear mechanism 4.2, etc. The above-mentioned mechanisms are independent of each other, and the power can be obtained through the gear pair formed by the gear at the end of each module and the sliding gear mechanism 1.2 on the power module.

[0032] The slip gear mechanism 1.2, which engages with the input end gears of the three fault simulation modules respectively through the slip gear on the power module 1, makes the AC motor 1.1 provide power for them; and through the reducer in front of each fault simulation module ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com