Novel double-block type track panel coarse adjustment method

A double-block type, rail-row technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of high quality requirements for light and construction personnel, difficult to observe, etc., and achieves a reasonable and reliable rough adjustment method, less labor, and economical effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A new method for rough adjustment of double-block rail rows. The specific construction steps are as follows: a. Place the laser pointing track ruler on a group of rail rows 9 that have been fine-tuned, and install prisms on the finely adjusted rail row beams. There is a cross line on the prism and a scale on the line, adjust the laser pointing track ruler to make it perpendicular to the rail of the rail row 9;

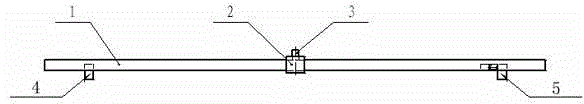

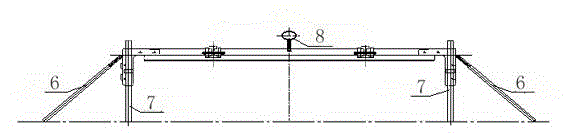

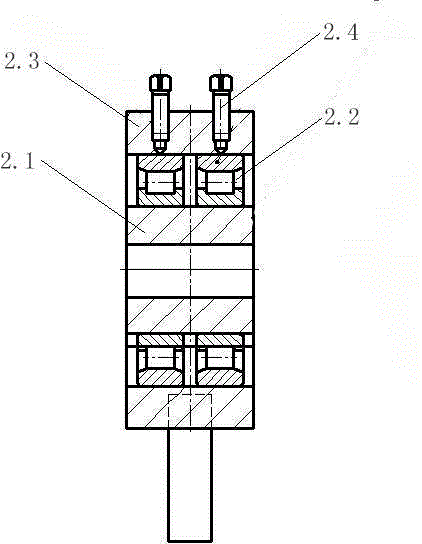

[0024] Such as figure 1 As shown, the laser pointing track ruler 10 includes a digital display track ruler 1 arranged on the rail row 9 and perpendicular to the rail row 9. One end of the digital display track ruler 1 is provided with a fixed end 4, and the digital display track ruler 1 is provided with a fixed end 4. 1 The other end is provided with a movable end 5, the fixed end 4 and the movable end 1 are respectively stuck on the inner sides of the rails on both sides, the digital display track ruler 1 is fixed with a rotating mechanism 2, and the rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com