Three-dimensional manual curve surface screen printing machine

A screen printing machine, three-dimensional technology, applied in the field of three-dimensional manual curved screen printing machine, can solve the problems of high production and use costs, broken screen pattern, complex structure, etc., to achieve low production and maintenance costs, Save printing cost and improve printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

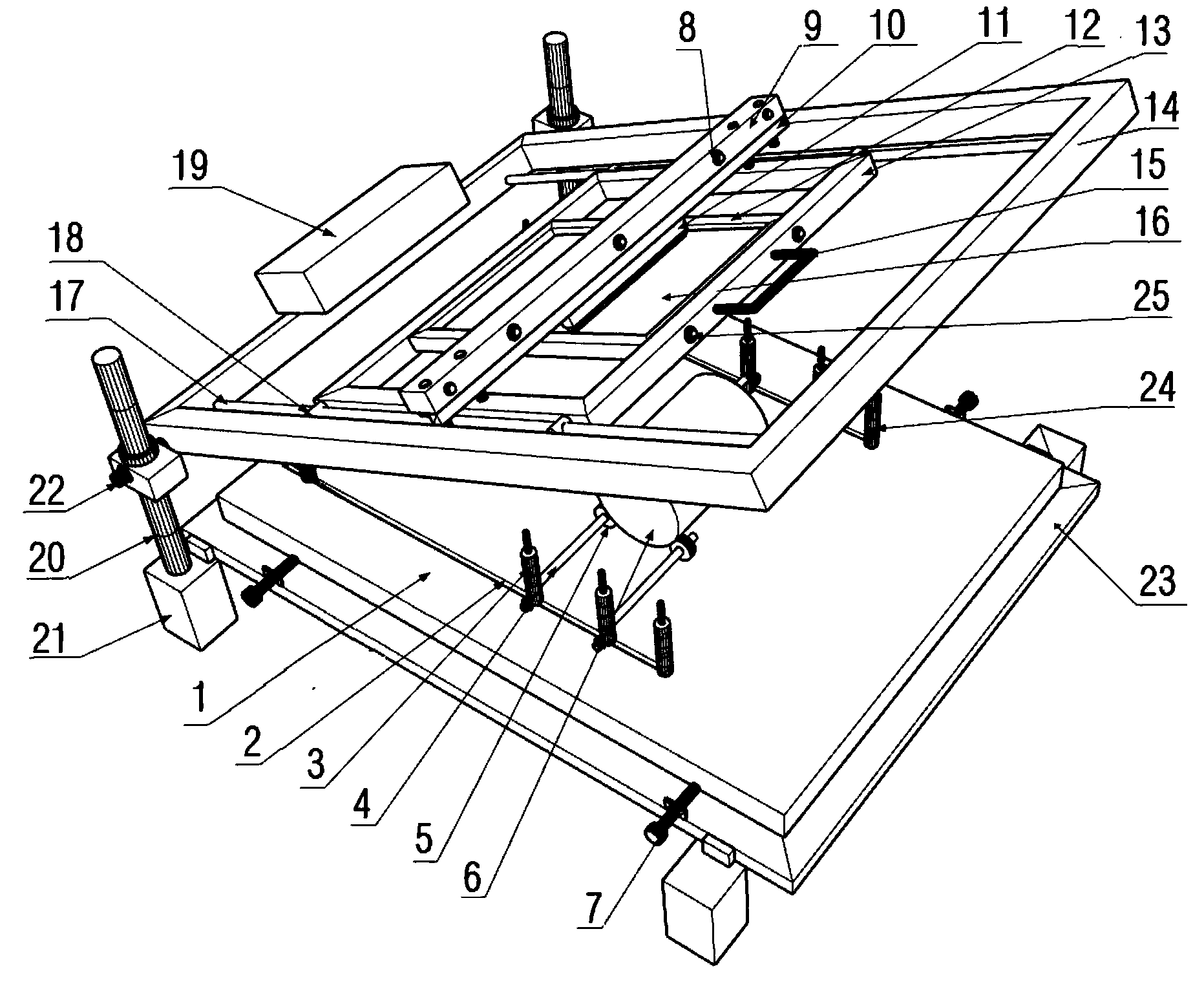

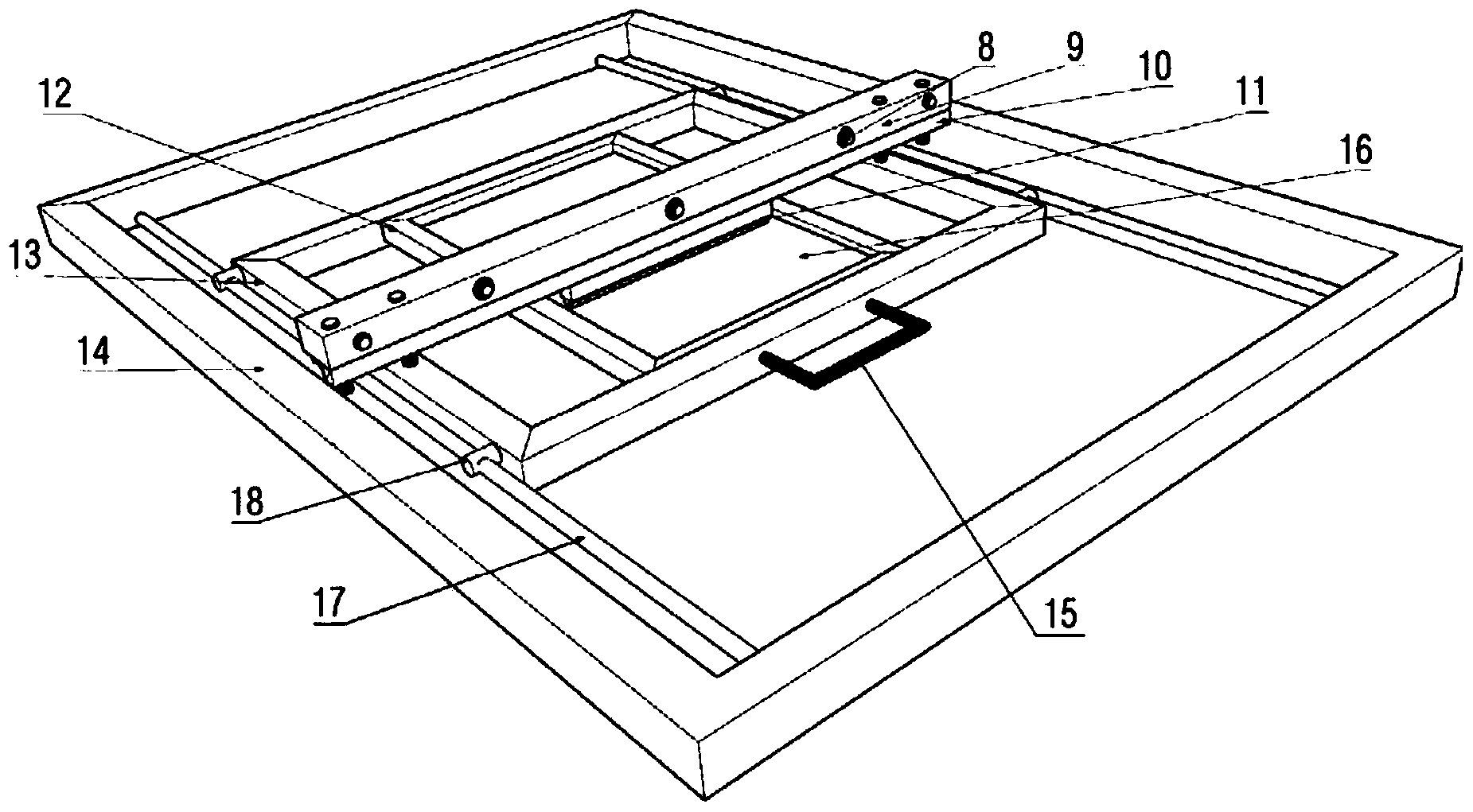

[0021] Embodiment 1: The present invention provides a kind of three-dimensional manual curved surface screen printing machine, its structure is as follows figure 1 Shown, comprise base plate 23, base plate support 21 and a set of spatial three-dimensional moving device, the four jiaos of described base plate 23 are provided with base plate support, and lifting screw rod 20 is installed on the base plate rear side two ends base plate support. The three-dimensional moving device in space is provided with upper and lower parts, the lower part is the three-dimensional moving mechanism for the substrate installed on the bottom plate 23; frame.

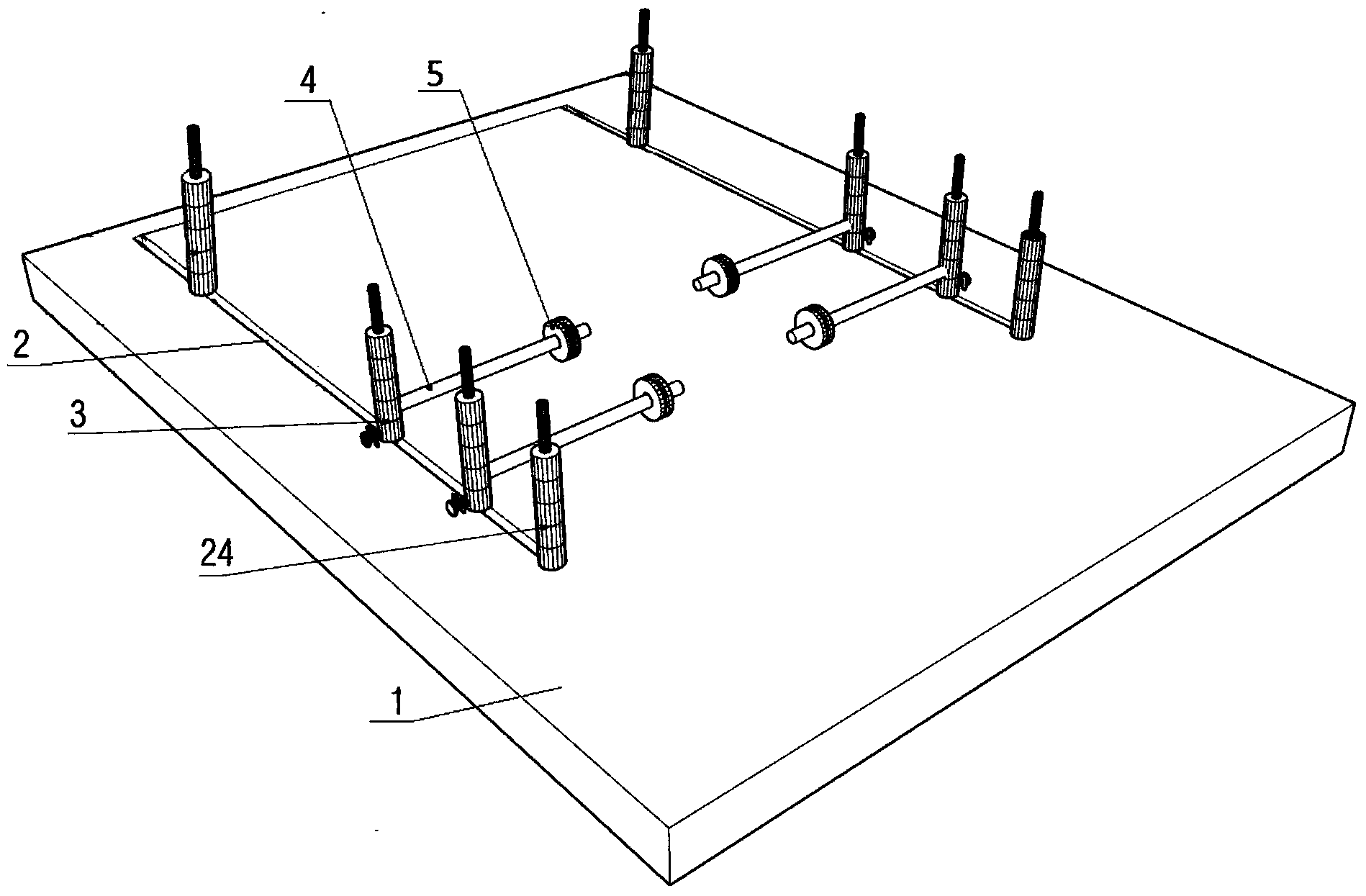

[0022] see figure 2 , the three-dimensional moving mechanism of the substrate in the lower part is provided with an operating platform 1, and two pairs of platform fixing bolts 7 are fixed on both sides of the operating platform. The platform fixing bolts 7 are used to adjust and slightly move the working angle of the operating platform; ...

Embodiment 2

[0025] Embodiment 2: Apply a kind of manual curved surface screen printing machine provided by Embodiment 1 of the present invention to print a relatively regular substrate 6, and its working process is as follows:

[0026] The first step: according to the shape of the substrate 6, adjust the vertical slide bar 3 and the horizontal slide bar 4 according to the present invention. After the sliding process determines a position point where the substrate is just placed, fix the vertical slide bar and the horizontal slide bar with nuts Horizontal slide bar, place the substrate on the four support bearings 5 with grooves, make the printing surface of the substrate 6 parallel to the screen plate 16, adjust the working position and state of the outer frame 14, and then adjust The vertical support bar 24 keeps the printing screen frame 12 and the screen screen 16 parallel to the outer frame 14 .

[0027] Step 2: Adjust the position of the scraper 11 in the scraper frame 9 so that th...

Embodiment 3

[0029] Embodiment 3: Apply the manual curved surface screen printing machine provided in Embodiment 1 of the present invention to print the substrate 6 with a handle, and its working process is as follows:

[0030] Step 1: According to the shape of the substrate 6, adjust the distance between the two vertical slide bars 3 on one side to change the distance between the horizontal slide bar 4 on the same side and the support bearing 5 on the same side to adapt to the printing The size of one side of the object, after determining a position that just places the substrate 6, fix the two vertical slide bars 3 and horizontal slide bars 4 on this side with nuts, and adjust the two sides on the other side in the same way. The distance between the two vertical slide bars is used to adapt to the size of the other side of the substrate, and after determining the position point, it is fixed; the curved surface substrate 6 is placed on the four supporting bearings 5 with grooves, Then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com