Method for manufacturing sheet-shaped packaging materials

A packaging material and sheet-like technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as insignificant crease lines, poor folding and forming effects, and leakage of packaging containers, and achieve Good shape stability of the container, good packaging forming ease, and the effect of avoiding damage caused by rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

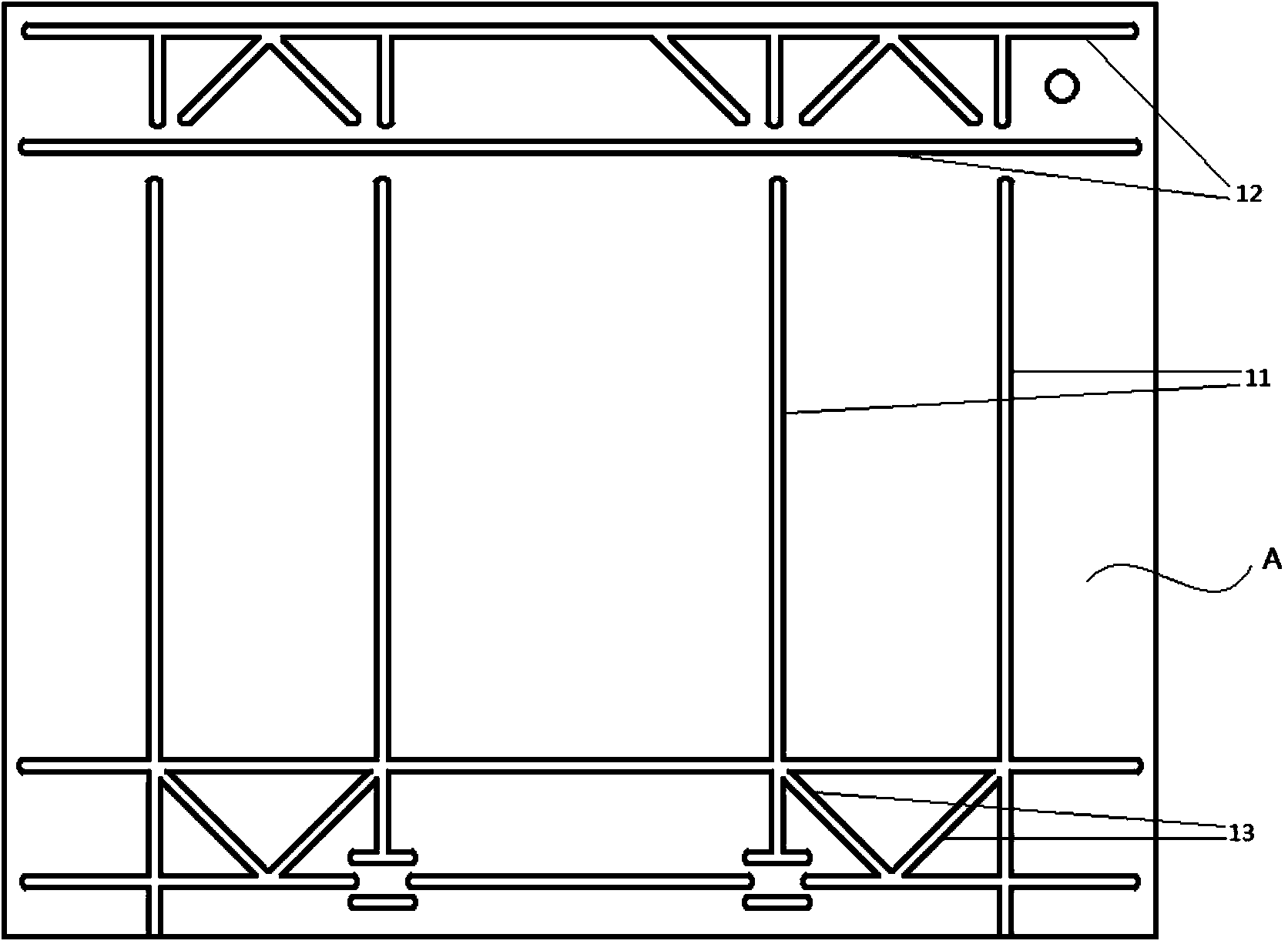

Image

Examples

Embodiment 1

[0025] A method of manufacturing sheet packaging material for forming packaging containers by slitting from a continuous packaging material comprising a plurality of sheet packaging material comprising sequentially laminated thermoplastic The outermost layer of material, printing layer, support layer, middle layer of thermoplastic material, aluminum foil layer, adhesive layer and innermost layer of thermoplastic material, including the following steps:

[0026] Step 1, unfolding the rolled paper core layer, punching open holes in the paper core layer, and the fiber direction of the paper core layer extends along the length direction;

[0027] Step 2, printing a printing layer on the outer surface of the paper core layer, and the direction of the pattern and text of the printing layer extends along the width direction of the paper core layer;

[0028] Step 3, extruding and laminating thermoplastic material on the printing layer to form the outermost layer;

[0029] Step 4, ext...

Embodiment 2

[0035] The difference from embodiment 1 is that the order of step 3 and step 4 is interchanged.

Embodiment 3

[0037] The difference from Embodiment 1 is that the order of the step 7 and the step 8 is exchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com