Fast desulfuration and dust removal device with multiple cavities

A desulfurization and dust removal, multi-chamber technology, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of single treatment method, insufficient mixing of atomized water and flue gas, and unreasonable use of treatment chambers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

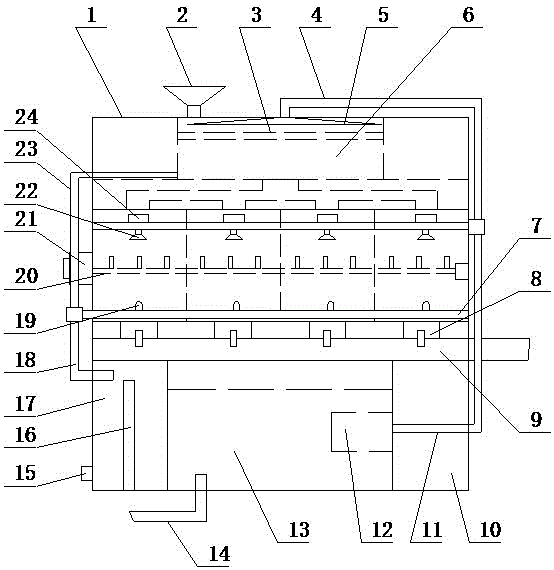

[0017] Such as figure 1 As shown, a multi-chamber rapid desulfurization and dust removal device according to the present invention includes a reaction box 1, which is divided into five layers from top to bottom, which are respectively the first chamber, the second chamber, the second chamber Three chambers, a fourth chamber and a fifth chamber; the third chamber is evenly divided into four filter chambers A, a rotating motor 21 is arranged on the left side of the third chamber, and the rotating motor 21 is connected to a stirring shaft 20, the stirring shaft 20 is set in the third chamber, interspersed in the four filter chambers A; the upper part of the third chamber is provided with a horizontal water pipe, and the horizontal water pipe is provided with four rotary atomizing nozzles 22, the four The rotary atomizing nozzles 22 correspond to the upper parts of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com