Double-layered foaming hydrocolloid dressing and preparation method thereof

A technology of foaming water and hydrocolloid, which is applied in the medical field, can solve the problems of peripheral skin damage, no antibacterial properties, and low absorption efficiency, etc., and achieve the effect of reducing anti-inflammatory effects, reducing scar formation, and promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

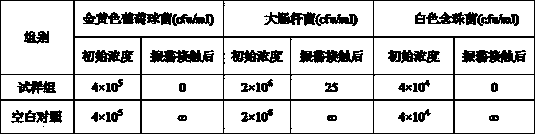

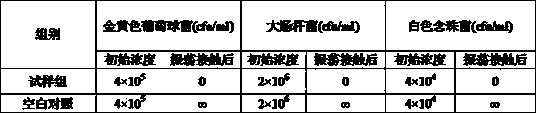

Examples

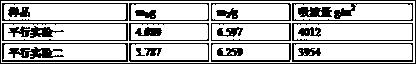

Embodiment 1

[0022] The foamed hydrocolloid is prepared as follows: Weigh 17.5g of SIS copolymer, 8.1g of polyisobutylene, 10.9g of rosin pentaerythritol ester, 1.3g of antioxidants and 17.4g of mineral oil and add them to a blade mixer for banburying at 115°C. 2h, then lower the temperature to 100℃ and banbury for 30min to obtain a liquid mixture. Then add 20g sodium carboxymethylcellulose, 8g cross-linked sodium carboxymethylcellulose and 0.05g silver nitrate into it and keep it at 100℃ Stir for 30 min to obtain a homogeneous mixture. After the last process is over, remove the mixture from the stirrer to cool down. At the same time, add 15g of ethylene propylene rubber to the stirrer and banbury for 10 minutes, then add the cooled mixture and stir with it, and banbury at 115°C for 30 minutes or Until a uniform hydrocolloid is formed.

[0023] Then the above-mentioned hydrocolloid glue slurry was stirred in an internal mixer at 80°C for 30 minutes, and sodium bicarbonate: citric acid = 2; 1...

Embodiment 2

[0034] The foamed hydrocolloid is prepared as follows: Weigh 17.5g of SIS copolymer, 8.1g of polyisobutylene, 10.9g of rosin pentaerythritol ester, 1.3g of antioxidants and 17.4g of mineral oil and add them to a blade mixer for banburying at 115°C. 2h, then cool down to 100℃ and banbury for 30min to obtain a liquid mixture, then add 22g sodium carboxymethylcellulose, 10g cross-linked sodium carboxymethylcellulose and 0.10g silver nitrate into it, keep it at 100℃ Stir for 30 min to obtain a homogeneous mixture. After the last process is over, remove the mixture from the stirrer to cool down. At the same time, add 15g of ethylene propylene rubber to the stirrer and banbury for 10 minutes, then add the cooled mixture and stir with it, and banbury at 115°C for 30 minutes or Until a uniform hydrocolloid is formed.

[0035] Then the above-mentioned hydrocolloid glue slurry was stirred in an internal mixer at 80°C for 30 minutes, and sodium bicarbonate: citric acid = 2; 1 foaming agent...

Embodiment 3

[0046] The foamed hydrocolloid is prepared as follows: Weigh 17.5g of SIS copolymer, 8.1g of polyisobutylene, 10.9g of rosin pentaerythritol ester, 1.3g of antioxidants and 17.4g of mineral oil and add them to a blade mixer for banburying at 115°C. 2h, then cool to 100℃ and banbury for 30min to obtain a liquid mixture, then add 23g of sodium carboxymethylcellulose, 9g of cross-linked sodium carboxymethylcellulose and 0.5g of silver nitrate into it and keep it at 100℃ Stir for 30 min to obtain a homogeneous mixture. After the last process is over, remove the mixture from the stirrer to cool down. At the same time, add 15g of ethylene propylene rubber to the stirrer and banbury for 10 minutes, then add the cooled mixture and stir with it, and banbury at 115°C for 30 minutes or Until a uniform hydrocolloid is formed.

[0047] Then the above-mentioned hydrocolloid glue slurry was stirred in an internal mixer at 80°C for 30 minutes, and sodium bicarbonate: citric acid = 2; 1 foaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com