Cushioning shoemaking technology

A technology, shock absorbing pad technology, which is applied in the field of shoemaking by setting springs on the heel of the sole to achieve the shock absorbing effect. It can solve the problems of inability to absorb shock and protect the effect, complex process structure, etc., and achieve the effect of protecting the brain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

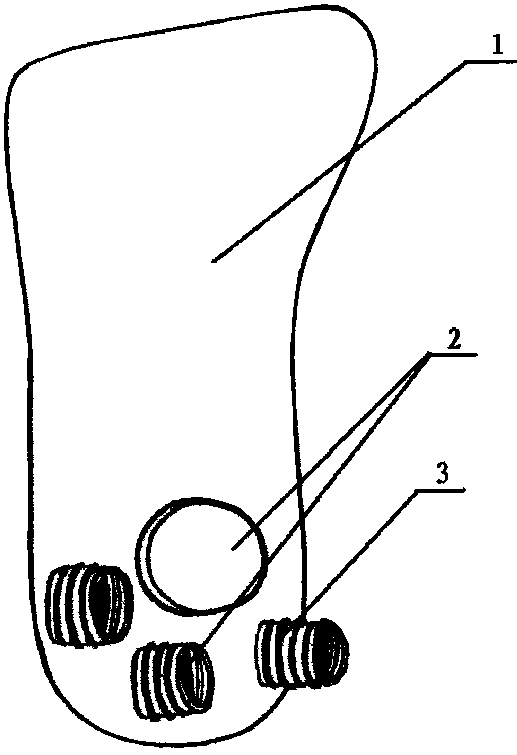

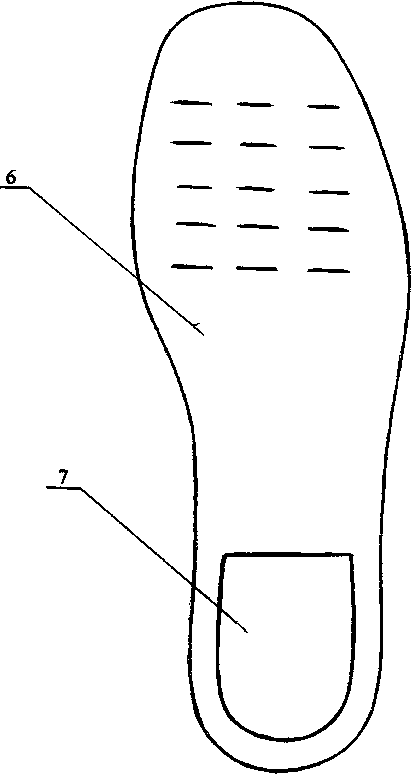

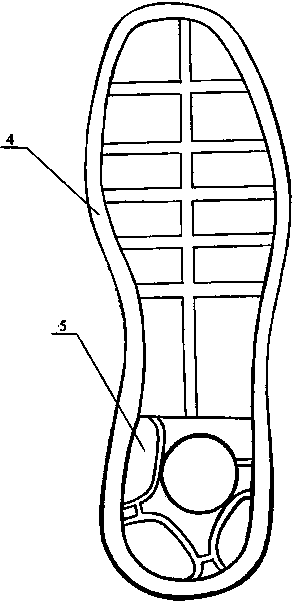

[0011] As shown in the figure, a shock-absorbing shoe-making technology is to put a shock-absorbing pad 1 in the inner cavity of the shoe, and there are a plurality of bosses 2 integrated with the shock-absorbing pad 1 under the shock-absorbing pad 1, and the bosses 2 is equipped with a spring 3 on the periphery; at the inner cavity of the heel of the sole 4, a plurality of partitions 5 are provided at the part corresponding to the boss 2 on the shock-absorbing pad 1, which are used to fix the boss 2 and prevent the shock-absorbing pad 1 from shifting , the shock absorbing pad 1 is integrated with the sole 1 through the hollow structure 7 of the heel of the midsole 6 .

[0012] Its technical principle is: when a person is walking or exercising, the spring is compressed by the gravity of the human body, which can dissipate and decompose the force and impact force of the human body, and play a buffering role; when the human body lifts the foot, the reaction force of the spring ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com