Optical fiber ribbonization apparatus and method

A strip-shaped, equipment technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of long processing time, high processing risk, low processing reliability, etc., to reduce processing time and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Illustrative embodiments are described below to disclose the teachings of the present invention by referring to the accompanying drawings. While the invention has been described herein with reference to illustrative embodiments for particular applications, it is to be understood that the invention is not limited thereto. Other modifications, applications, and implementations within the scope of the present invention and other important areas of application will be appreciated by those skilled in the art based on the teachings provided herein.

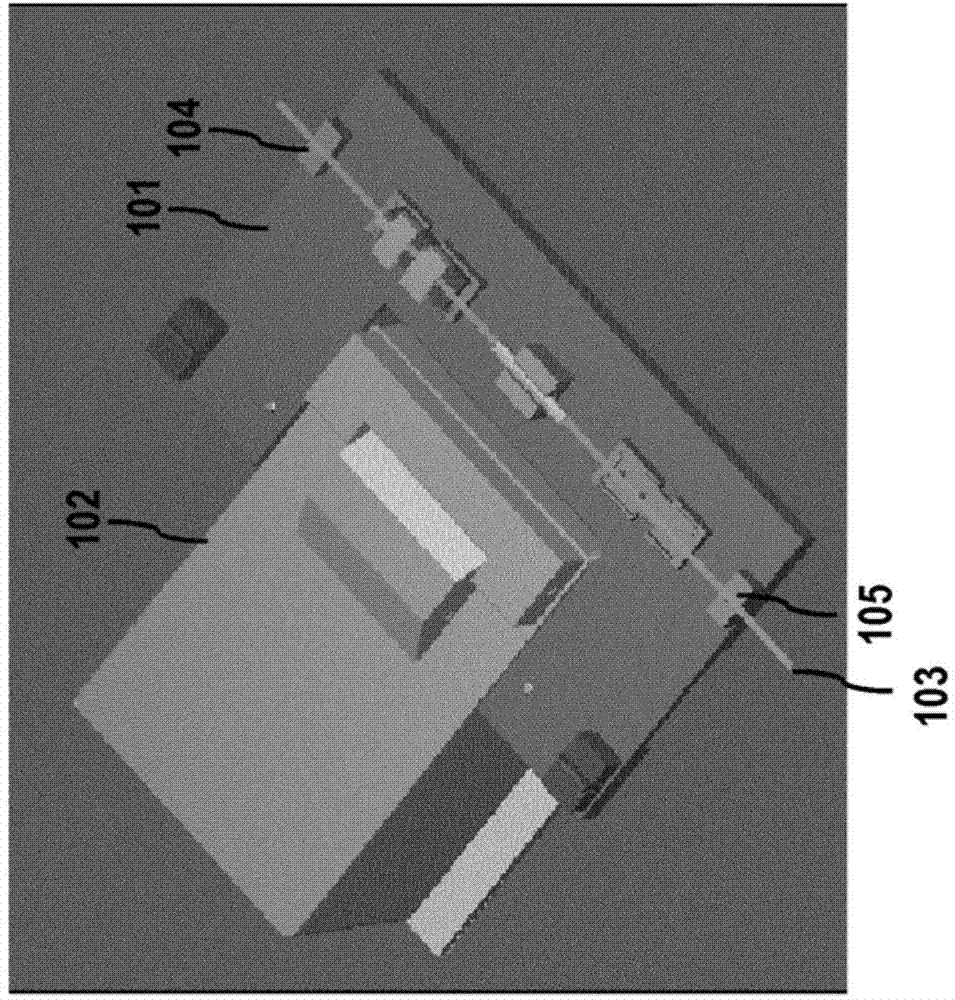

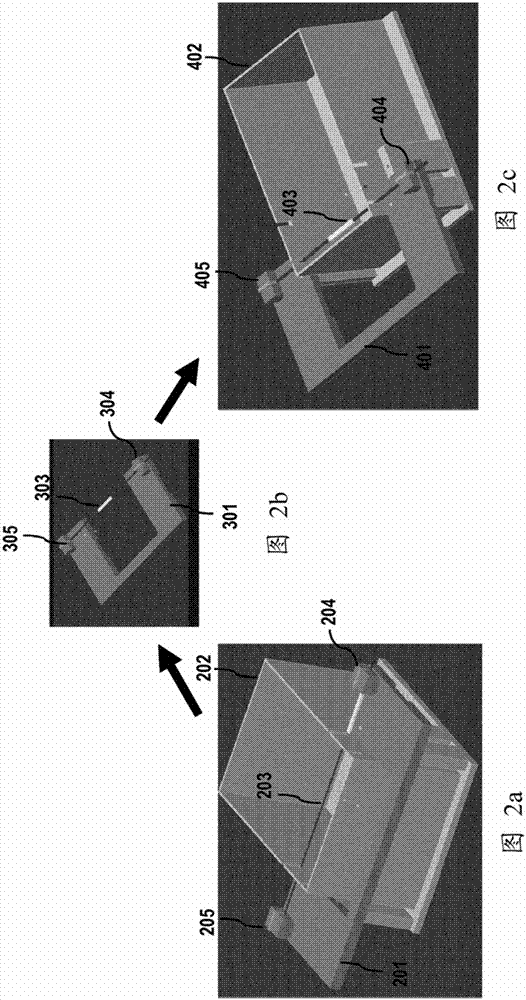

[0028] figure 1 is a schematic perspective view of an apparatus for splicing optical fibers into a ribbon according to an embodiment of the present invention. In the figure is shown a plate 101 comprising fiber alignment means 104 and 105 for aligning a plurality of parallel optical fibers 103; figure 1 The shown device for splicing optical fibers into a ribbon is disposed in and spliced with the splicing device 102 . The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com